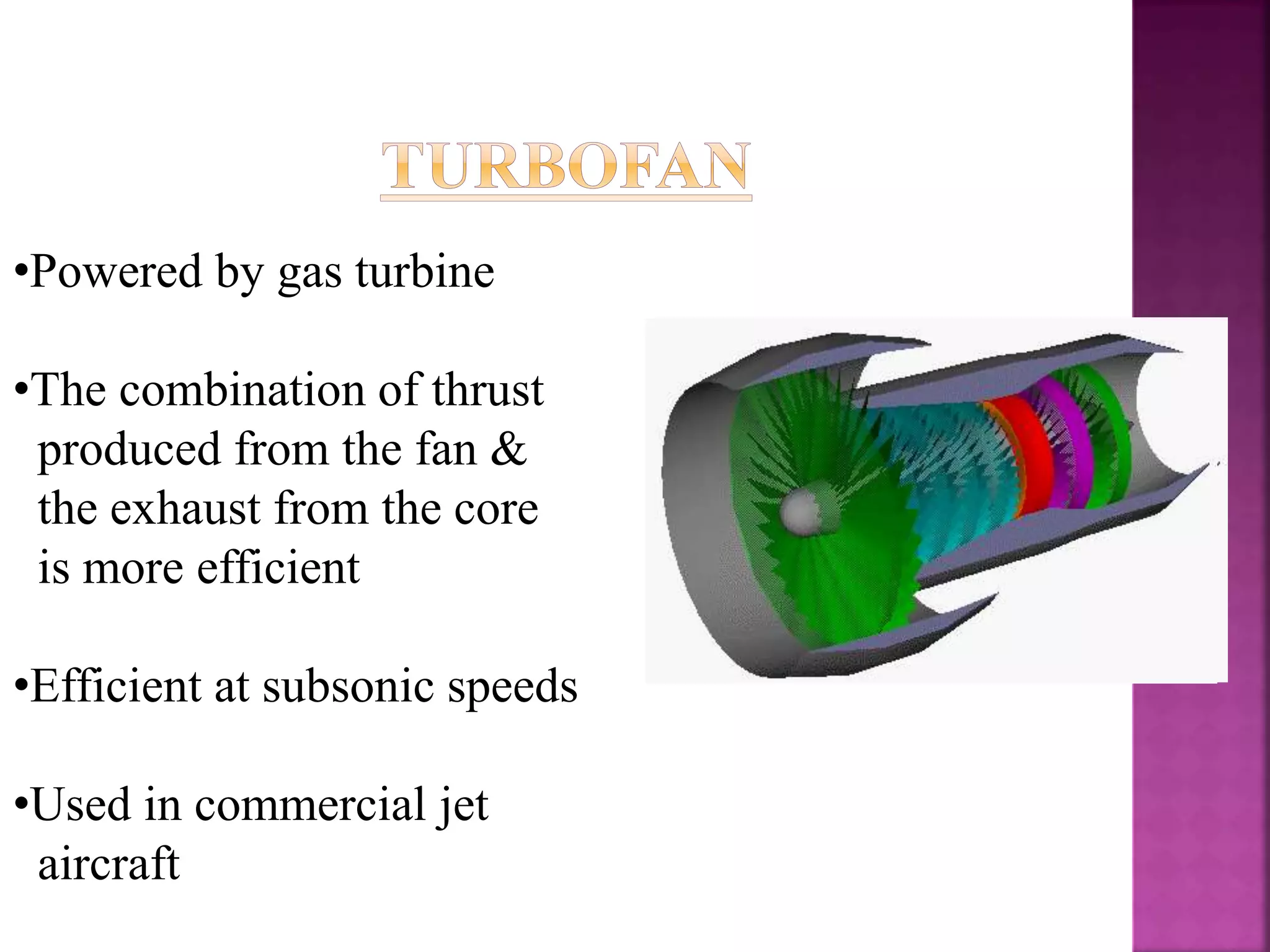

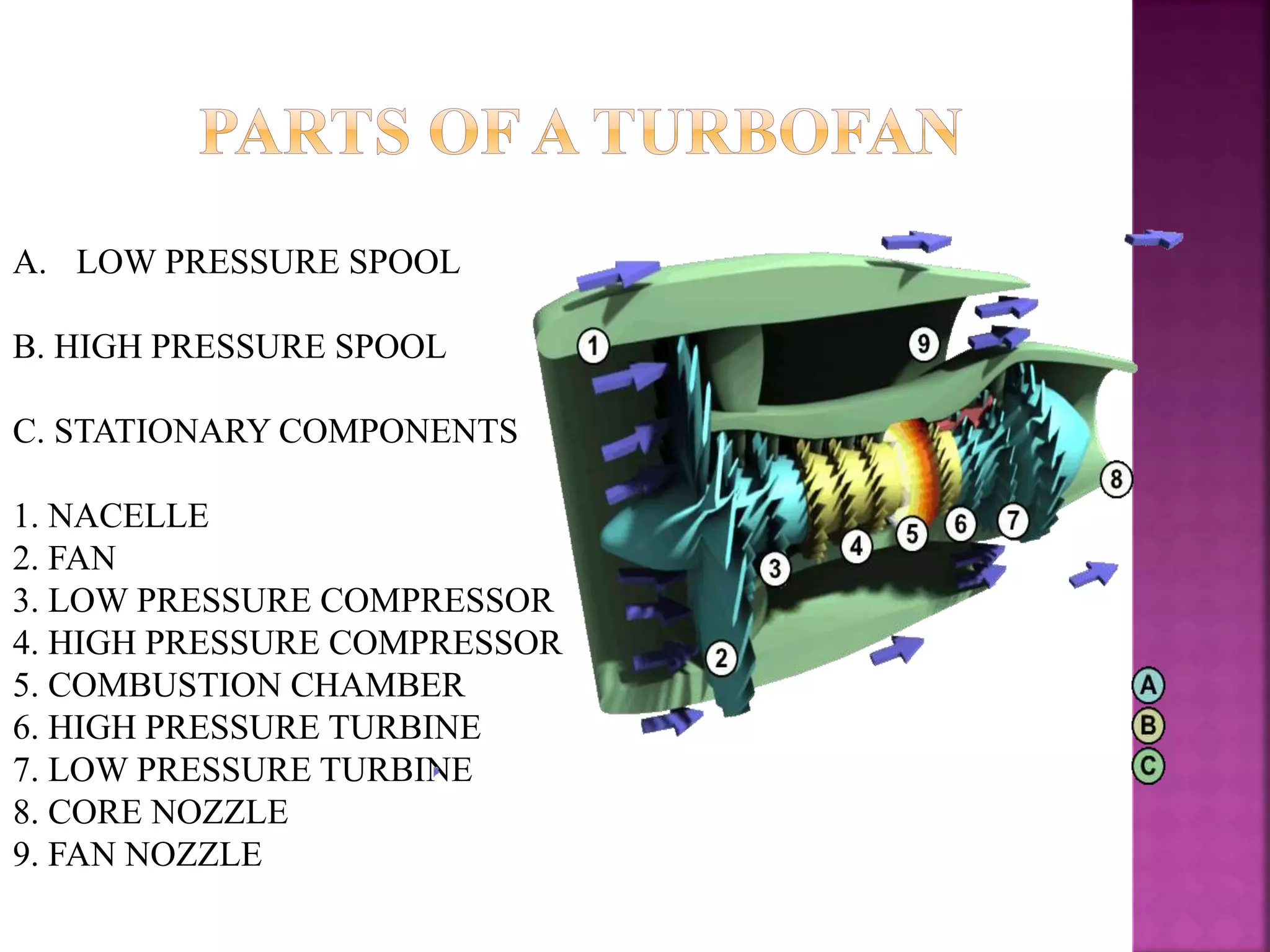

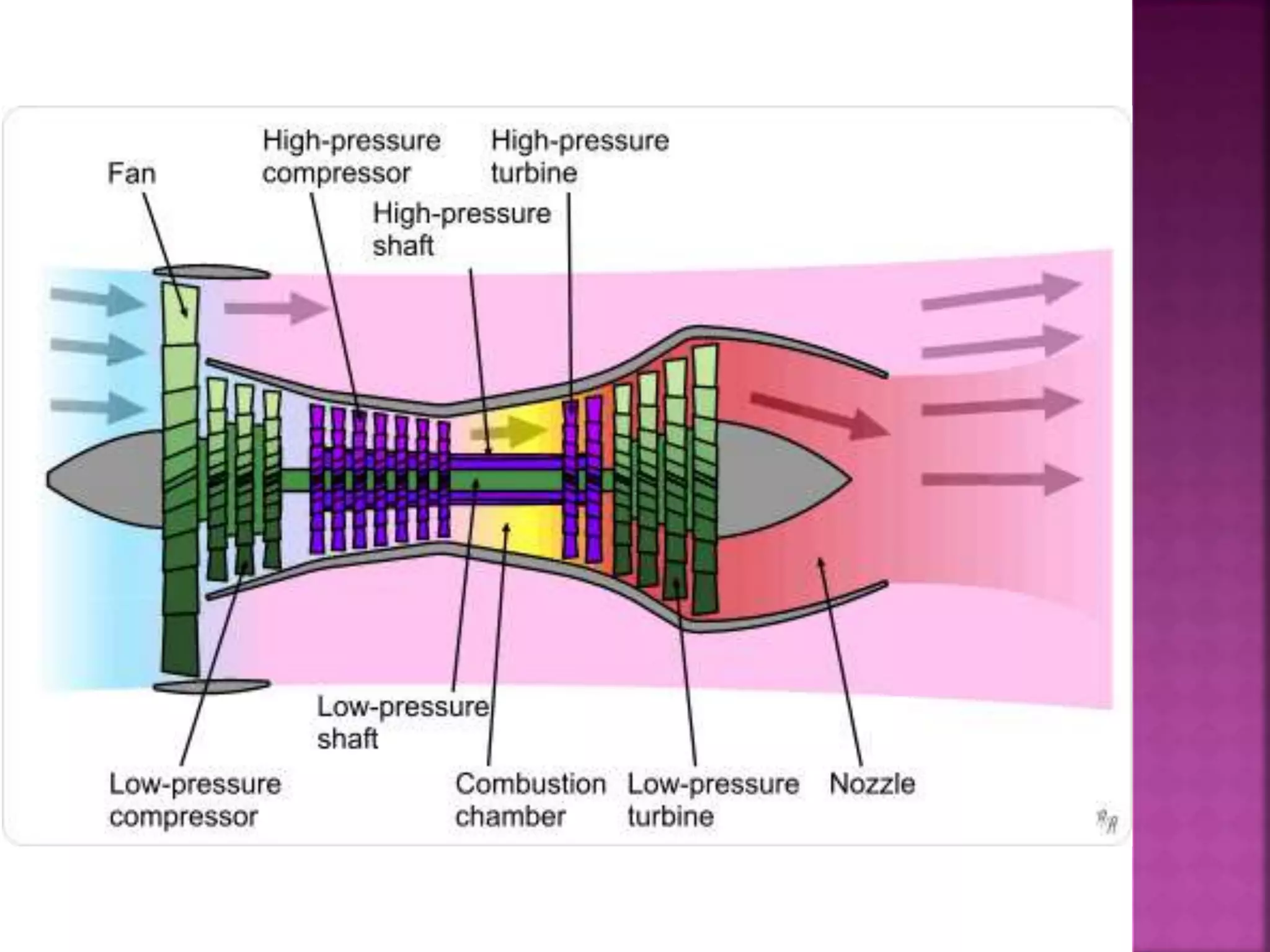

The document discusses turbofan engines, explaining their components, operation, advantages, and historical development. It highlights the efficiency of turbofans at subsonic speeds and the technological advancements in reducing noise and improving performance. Future applications, such as the geared turbofan concept, are also mentioned, showcasing the potential for enhanced fuel efficiency and performance.