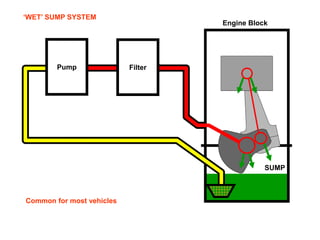

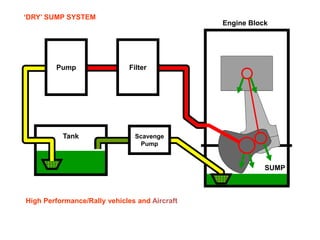

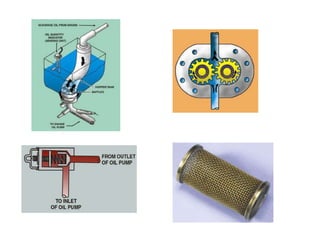

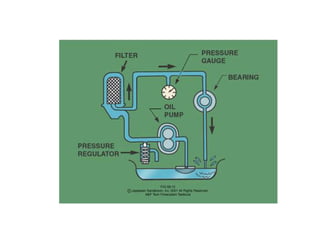

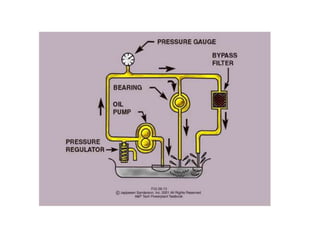

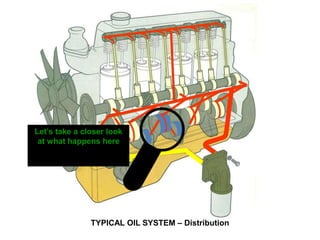

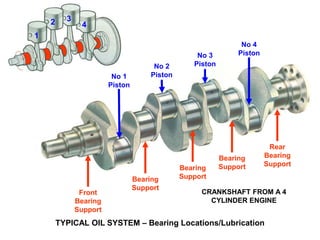

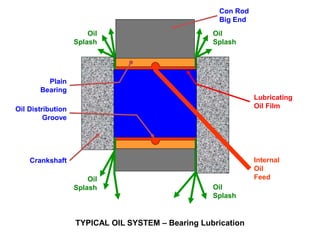

Lubricating oil is essential for piston engines to reduce friction and wear between moving parts. It also removes heat from the engine. There are two main types of lubrication systems - wet sump and dry sump. Wet sump systems carry the oil in the engine crankcase, while dry sump systems store oil externally. Pressure lubrication is the primary method used, relying on pumps to circulate pressurized oil through the engine. Filters help clean the oil before it reaches critical components.