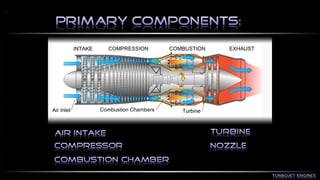

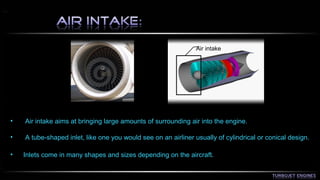

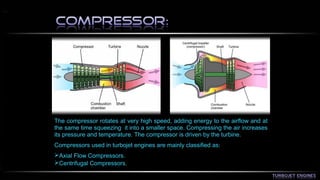

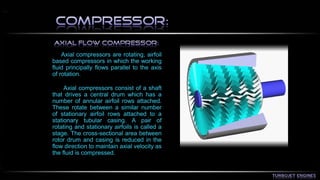

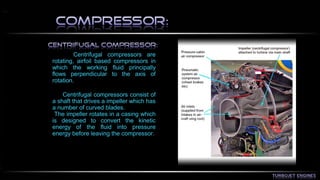

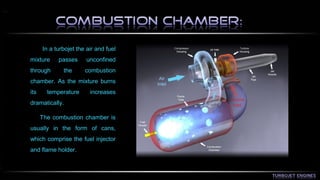

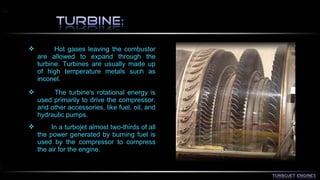

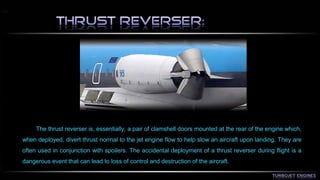

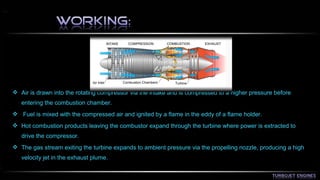

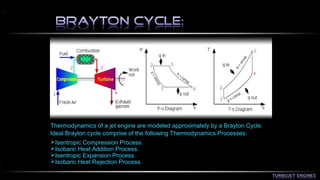

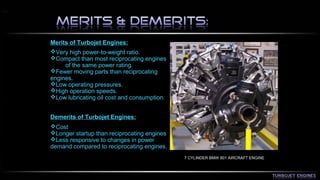

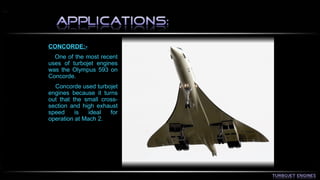

The document discusses the mechanical design of a turbojet engine. It describes the primary components including the air intake, axial and centrifugal compressors, combustion chamber, turbine, exhaust nozzle, and afterburner. It explains how turbojet engines operate based on the Brayton cycle and provides examples of their applications in early jet aircraft like the Messerschmitt Me 262 and Concorde. The summary highlights the key components and operating principles of a turbojet engine.