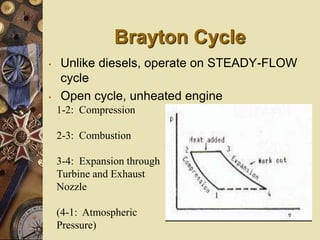

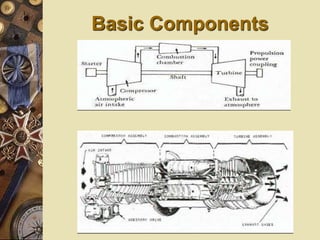

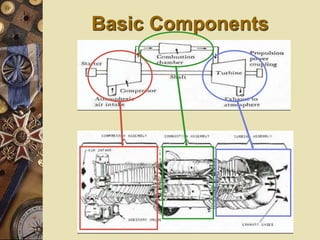

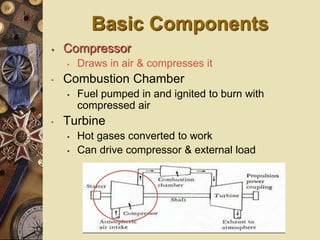

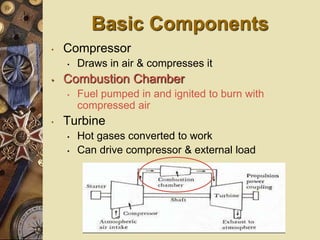

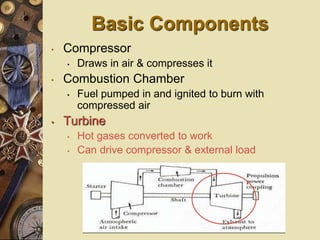

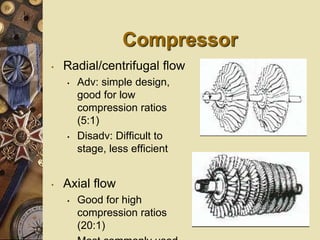

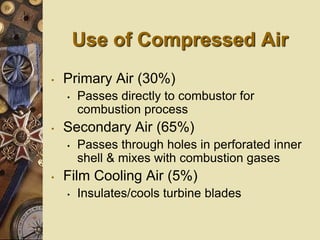

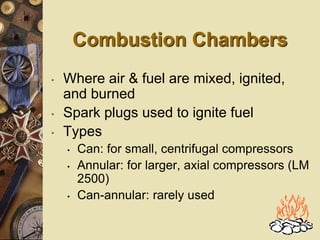

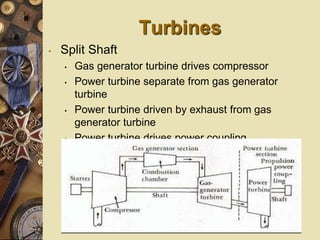

The document discusses the construction and operation of gas turbine engines, detailing their critical components including the compressor, combustion chamber, and turbine. It outlines the thermodynamic processes involved in the Brayton cycle, the types of compressors, and the different combustion chamber designs. Additionally, it compares gas turbines to steam turbines in terms of weight reduction, maintenance, and operational efficiency.