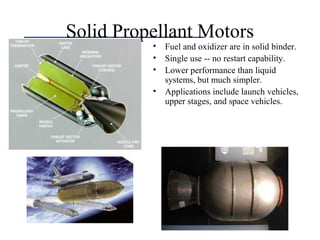

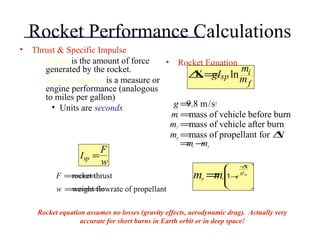

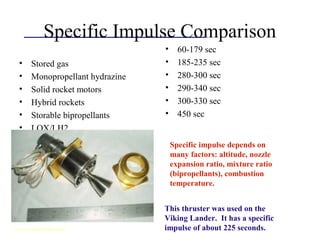

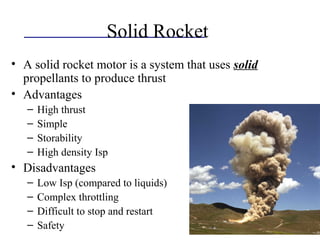

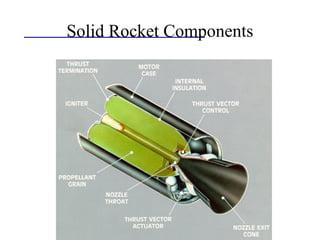

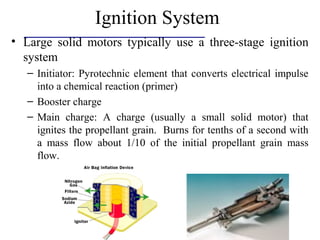

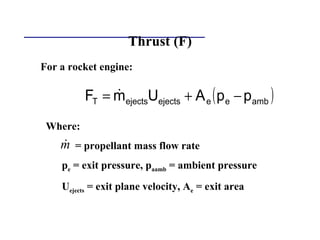

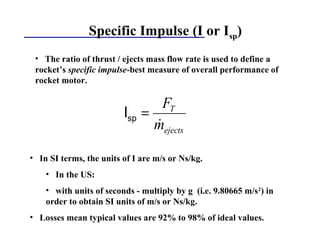

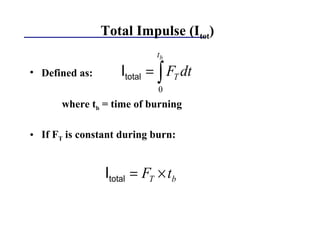

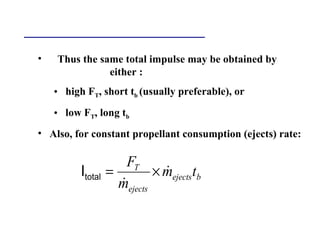

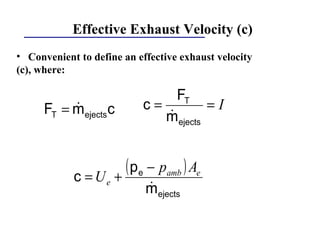

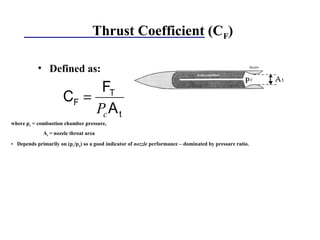

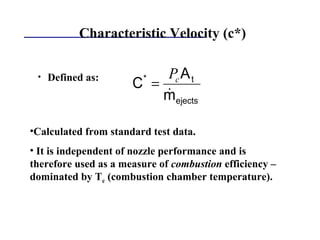

This document discusses solid rocket propulsion. It describes the key components of a solid rocket motor, including the thermal insulation, nozzle, ignition system, and solid propellant grain. Solid propellant grains can be composite, containing an oxidizer like ammonium perchlorate and a fuel like aluminum powder held together by a binder. Performance criteria for rockets include thrust, specific impulse, total impulse, and effective exhaust velocity. Solid rockets provide high thrust but have low control and cannot easily be shut down or restarted.