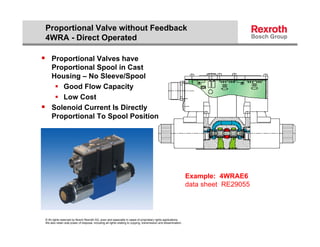

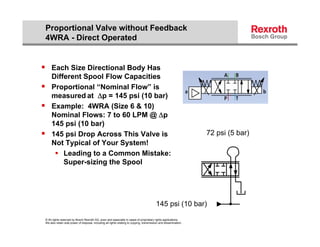

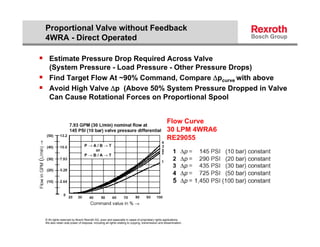

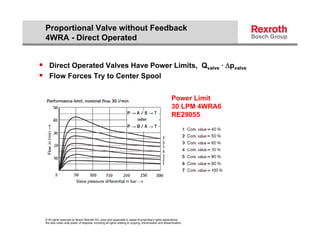

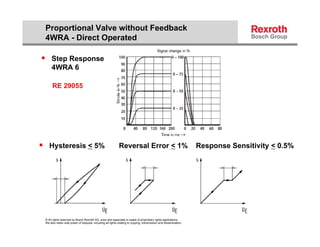

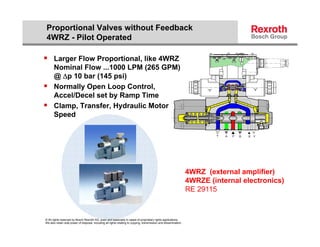

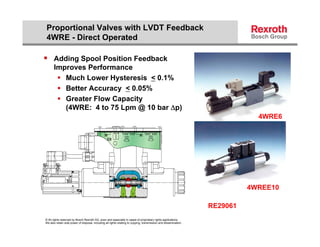

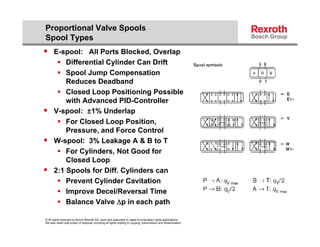

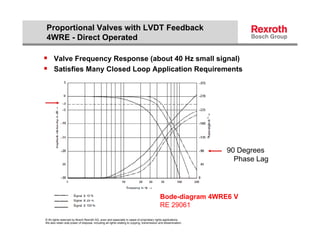

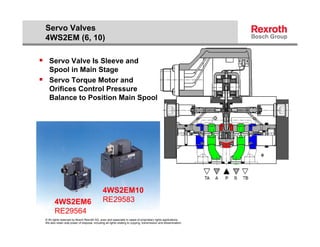

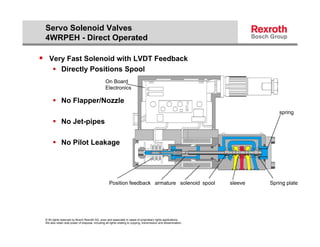

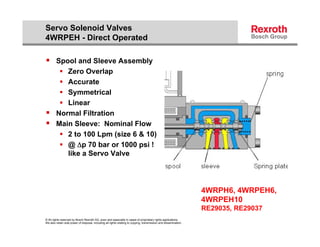

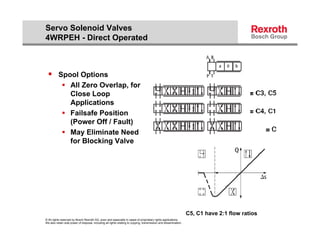

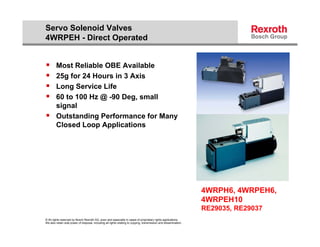

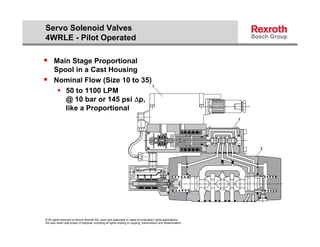

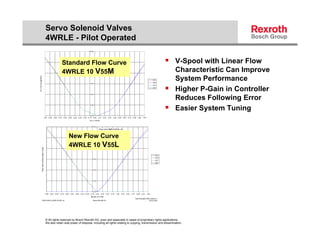

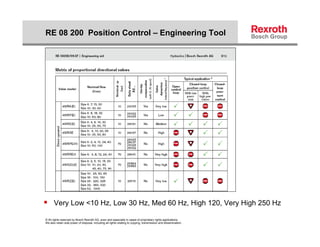

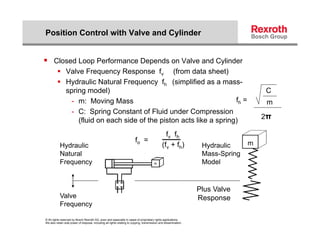

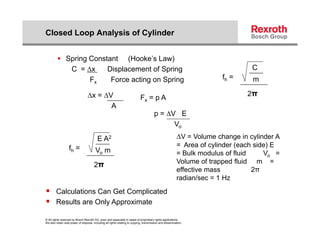

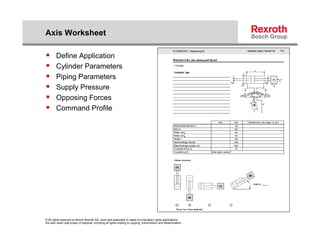

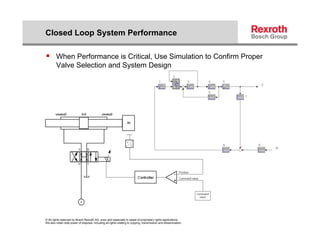

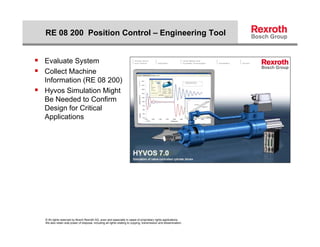

This document provides a comprehensive overview of selecting proportional and high response valves for various applications, emphasizing flow requirements, dynamic performance, and different valve categories. It details various types of proportional valves including direct operated and pilot operated designs, along with their flow capacities, characteristics, and feedback mechanisms to improve performance. Additionally, it discusses the significance of closed-loop systems and simulations for confirming proper valve selection and ensuring optimal performance.