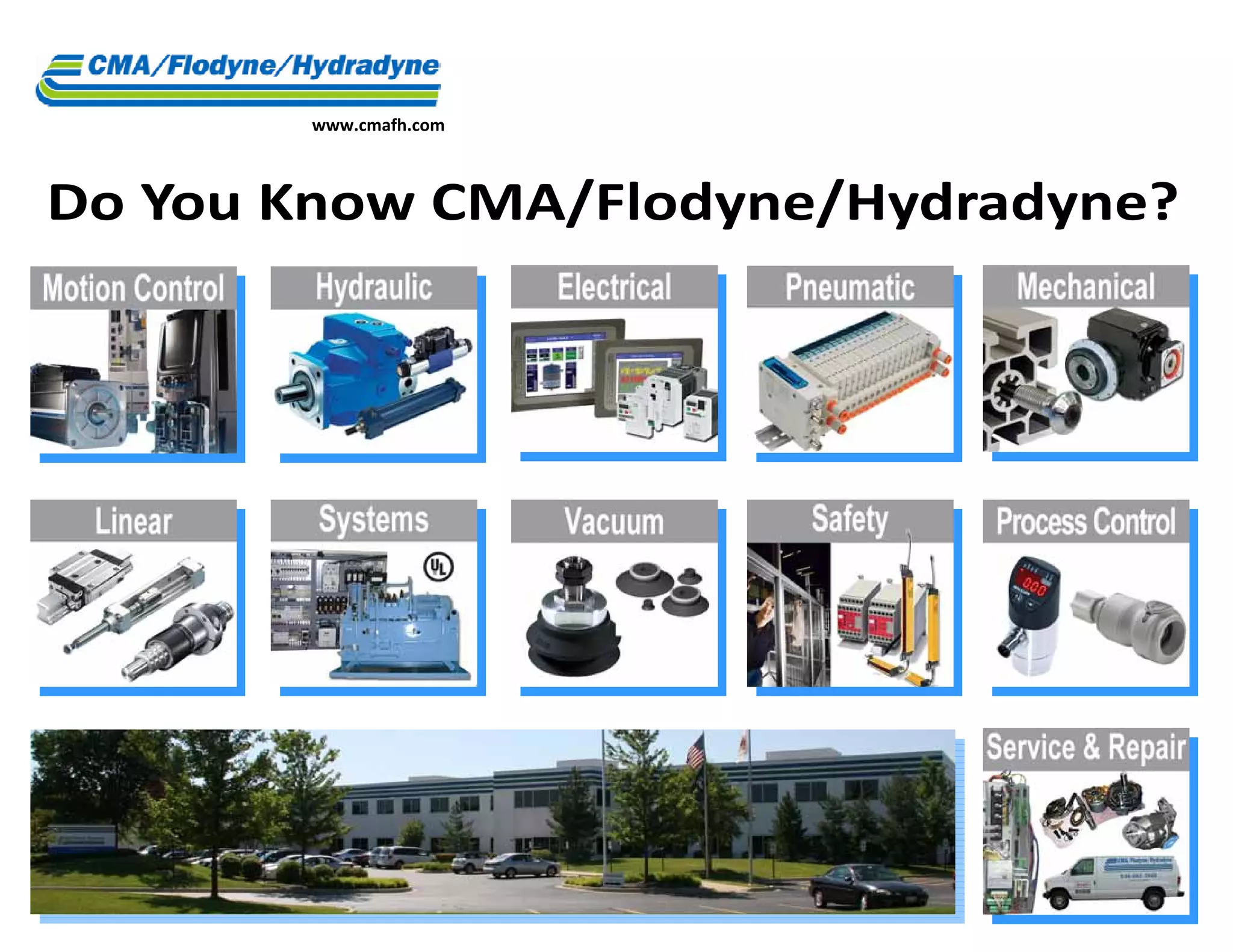

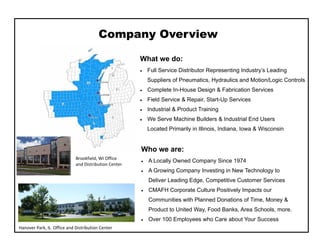

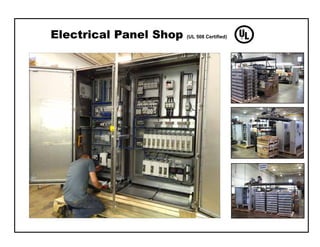

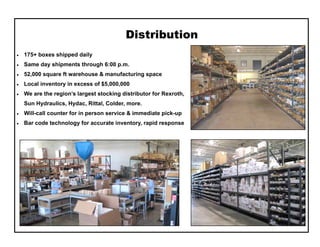

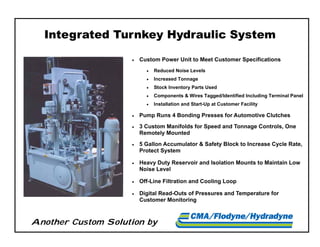

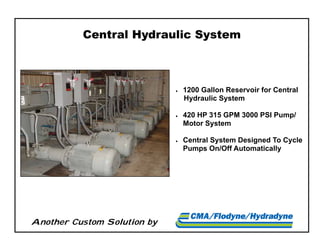

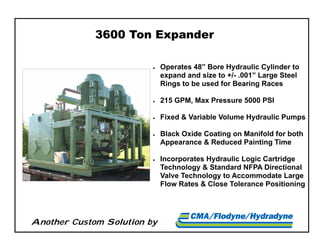

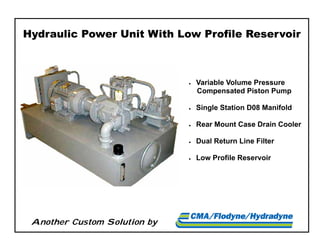

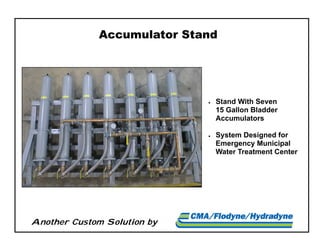

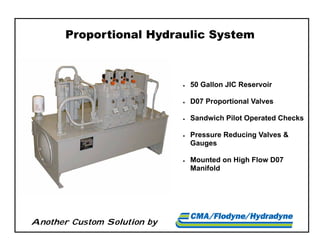

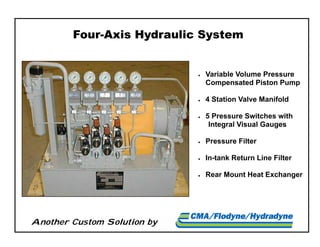

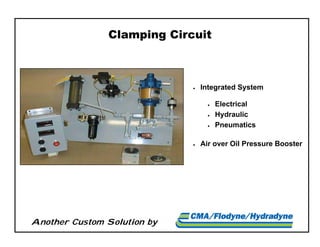

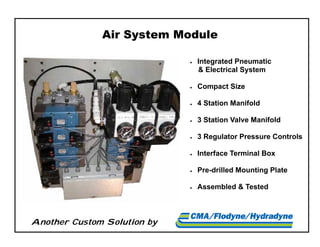

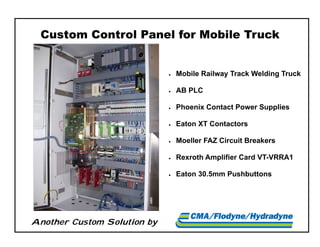

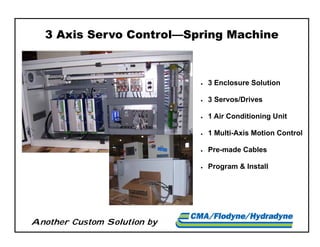

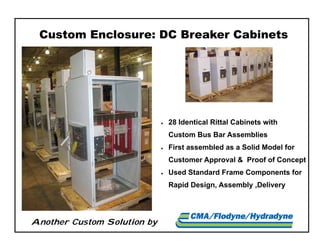

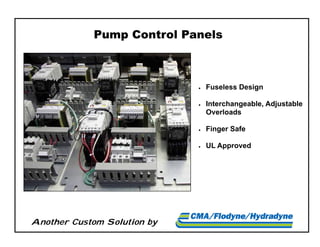

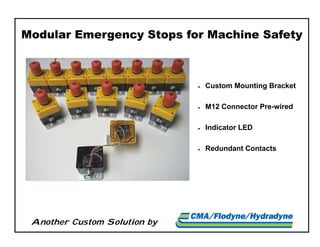

CMA/Flodyne/Hydradyne is a fluid power company that has been in business for over 30 years. In addition to fluid power, they also offer motion and logic controls, machine safety, field service, engineered systems, and warehouse distribution. The document provides details on their capabilities, partnerships, fabrication, field service, distribution, customer service, training programs, and examples of custom hydraulic systems they have created for customers.