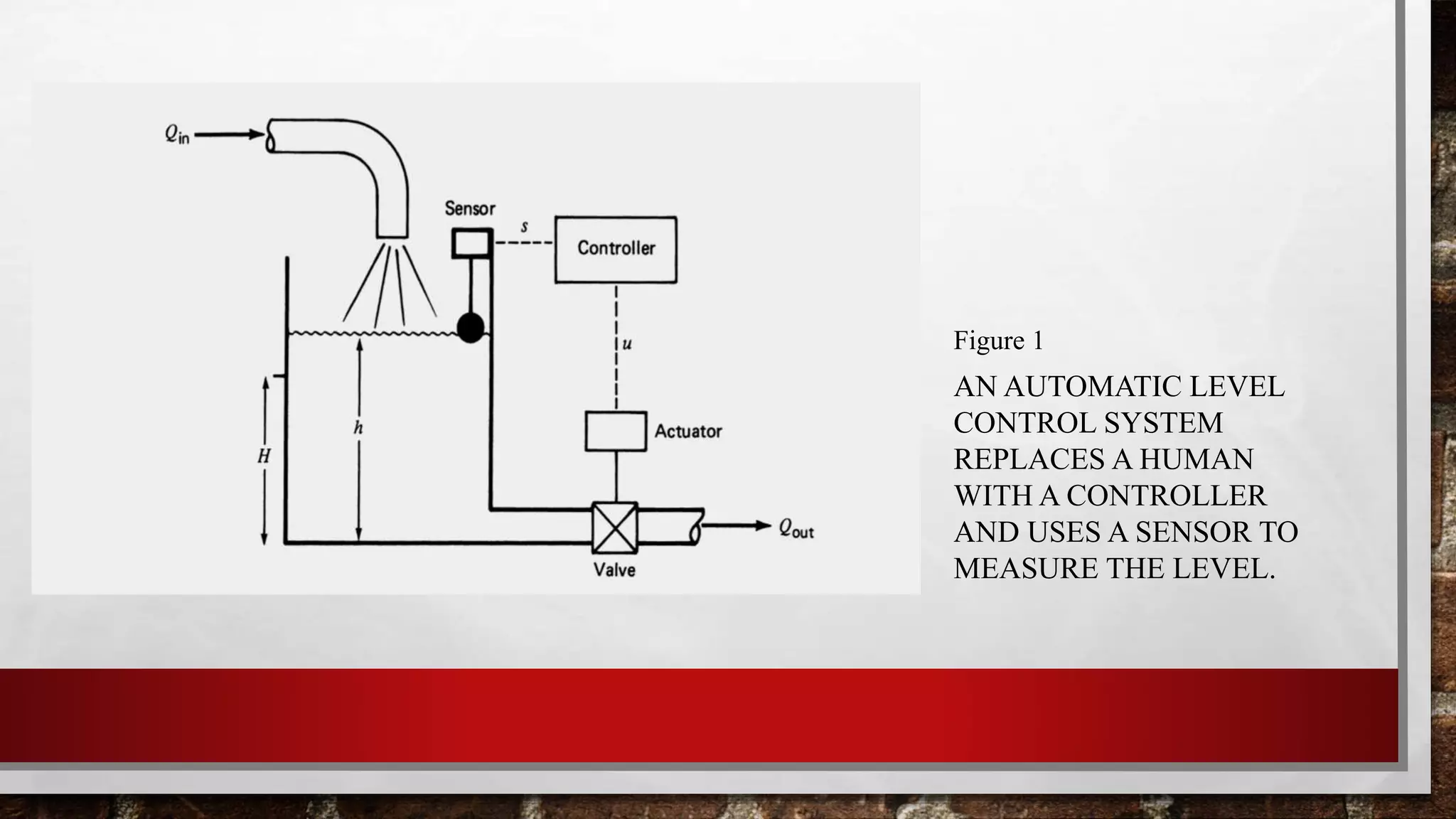

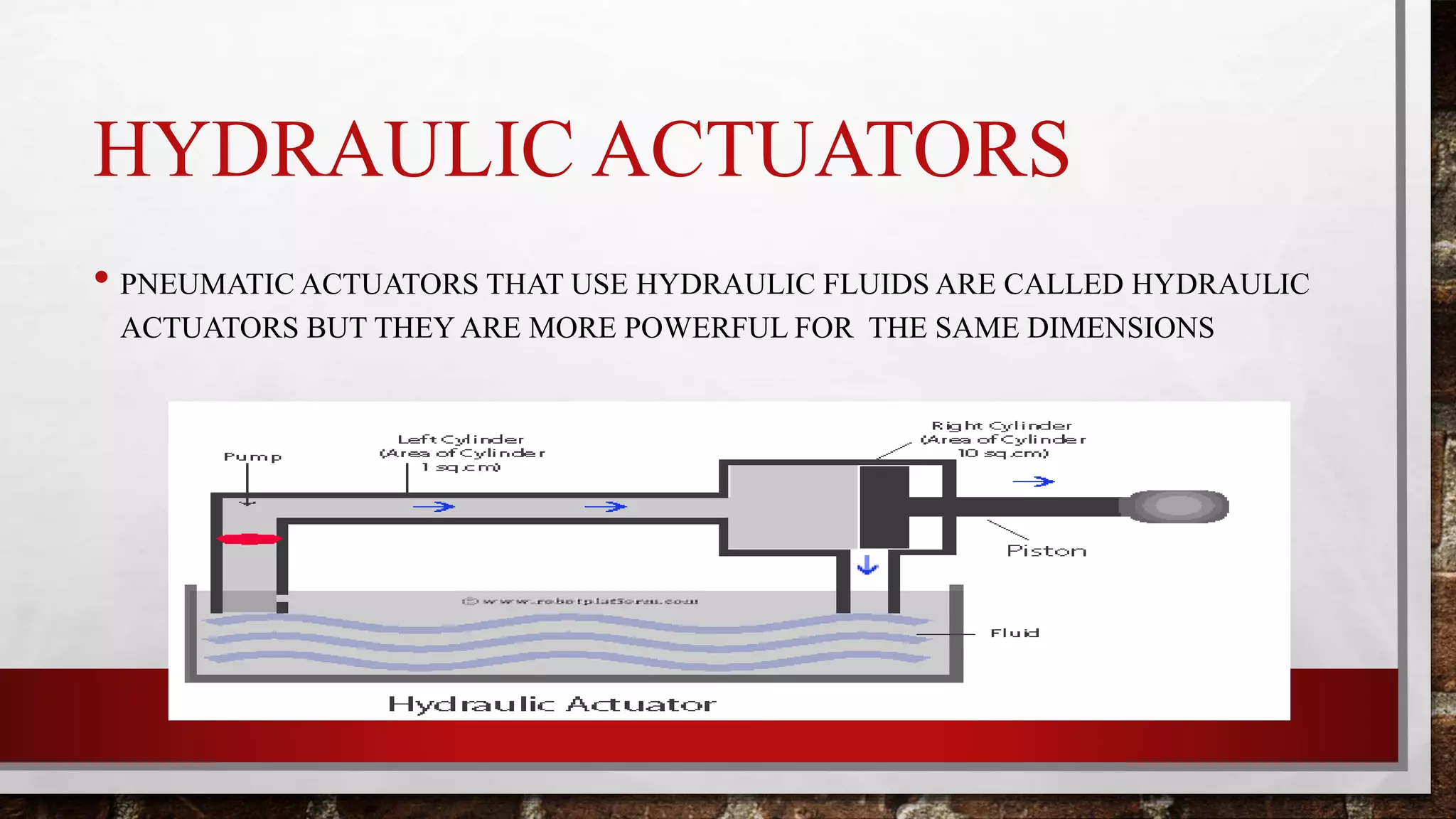

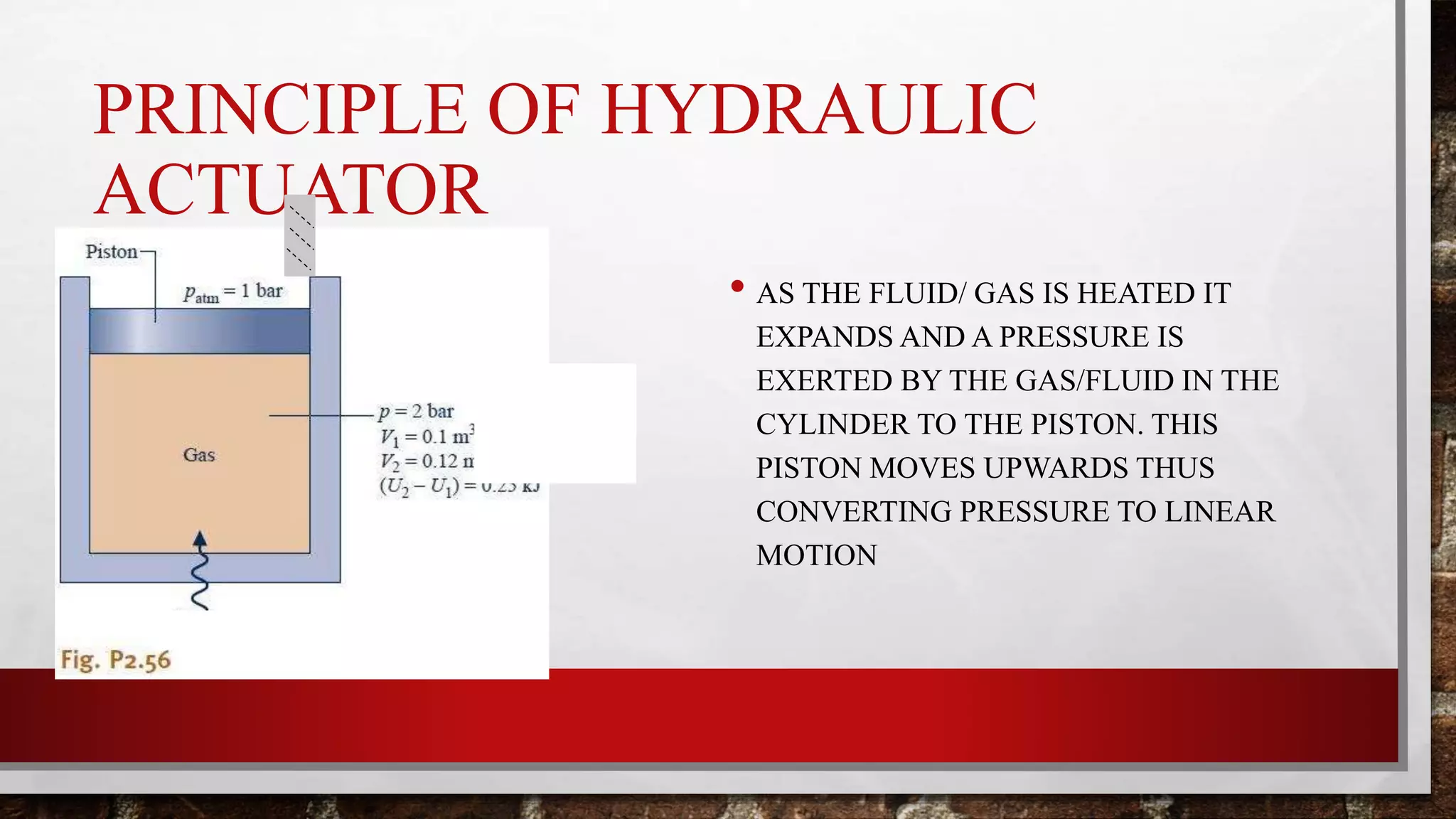

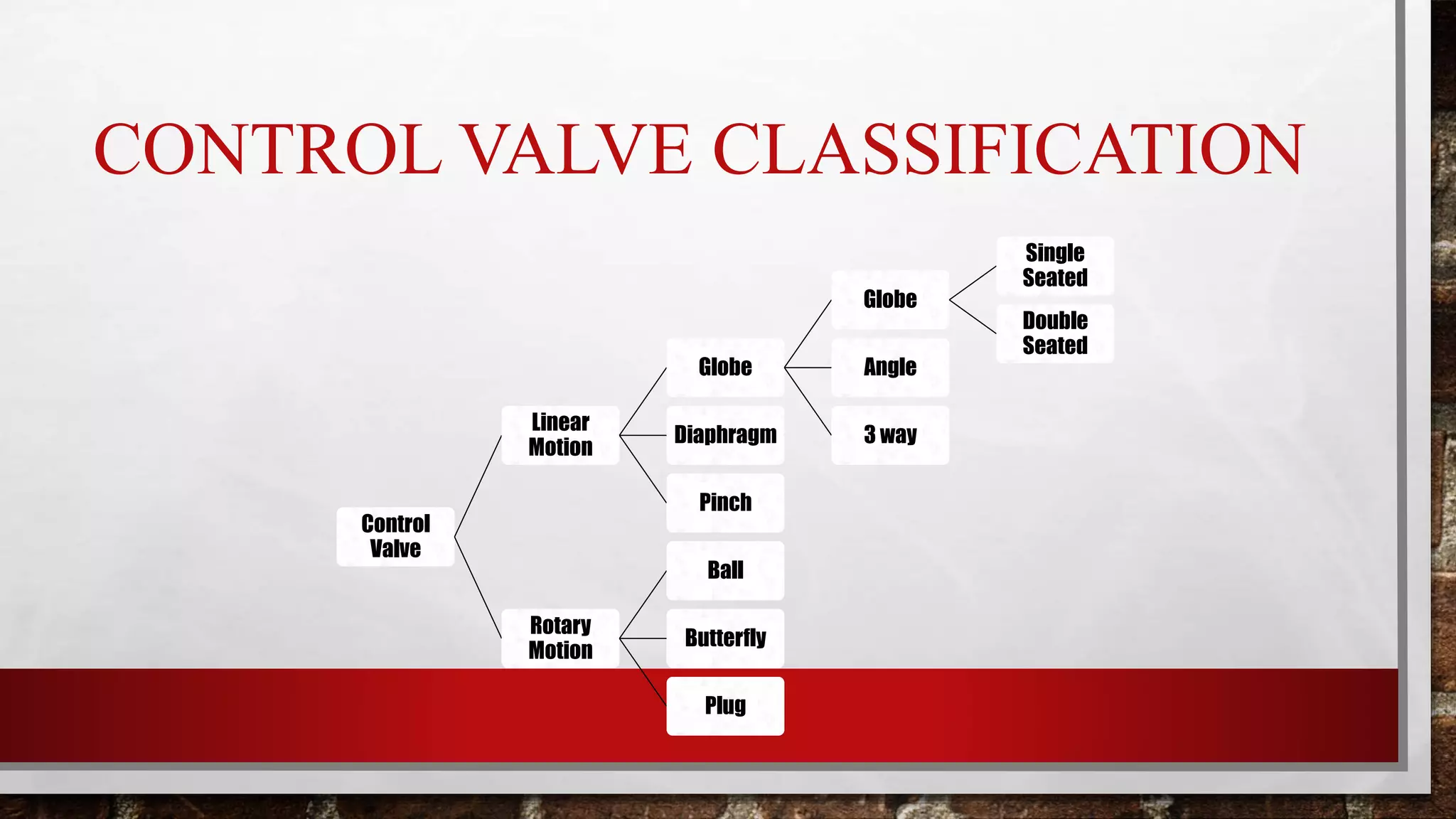

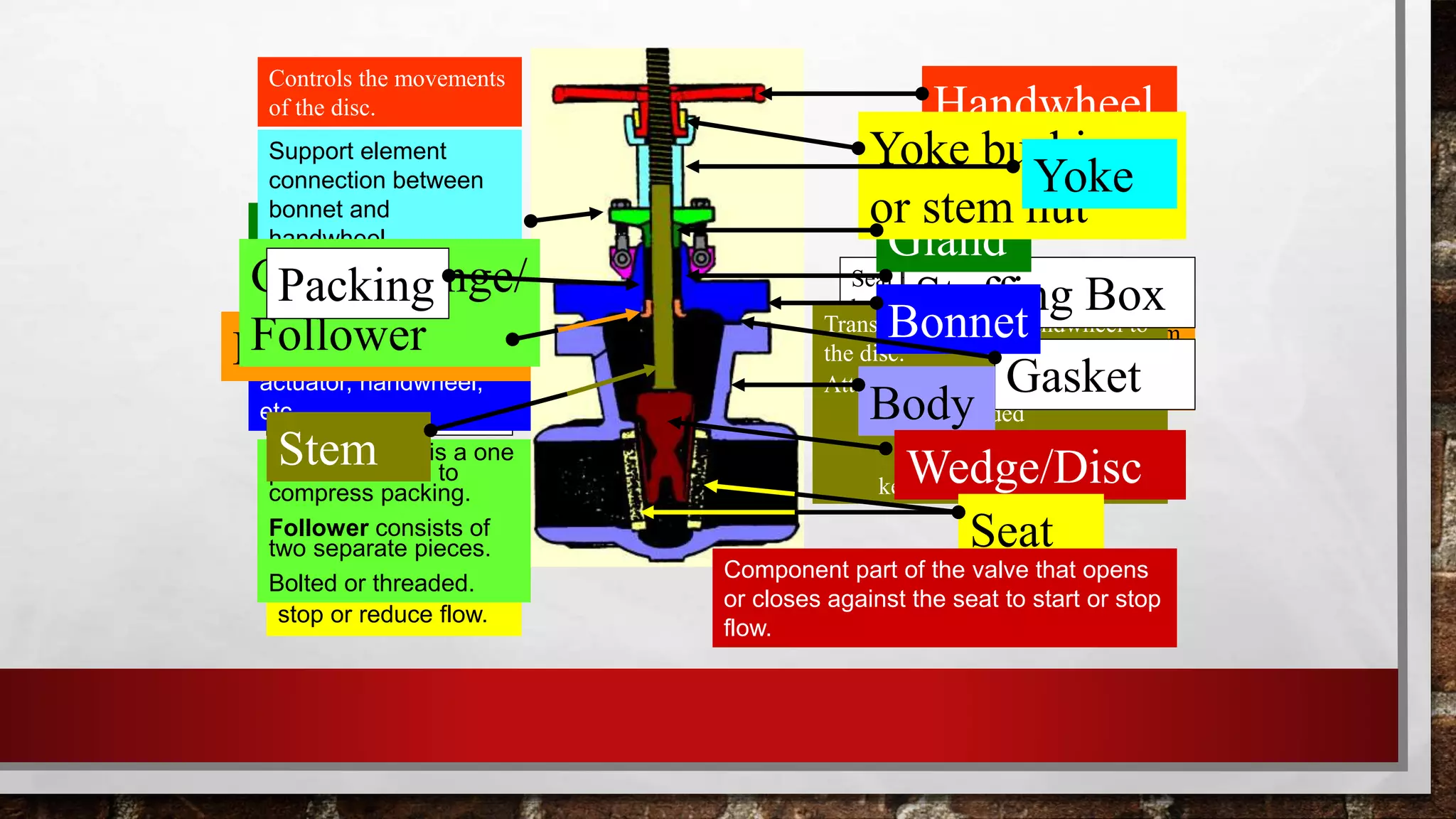

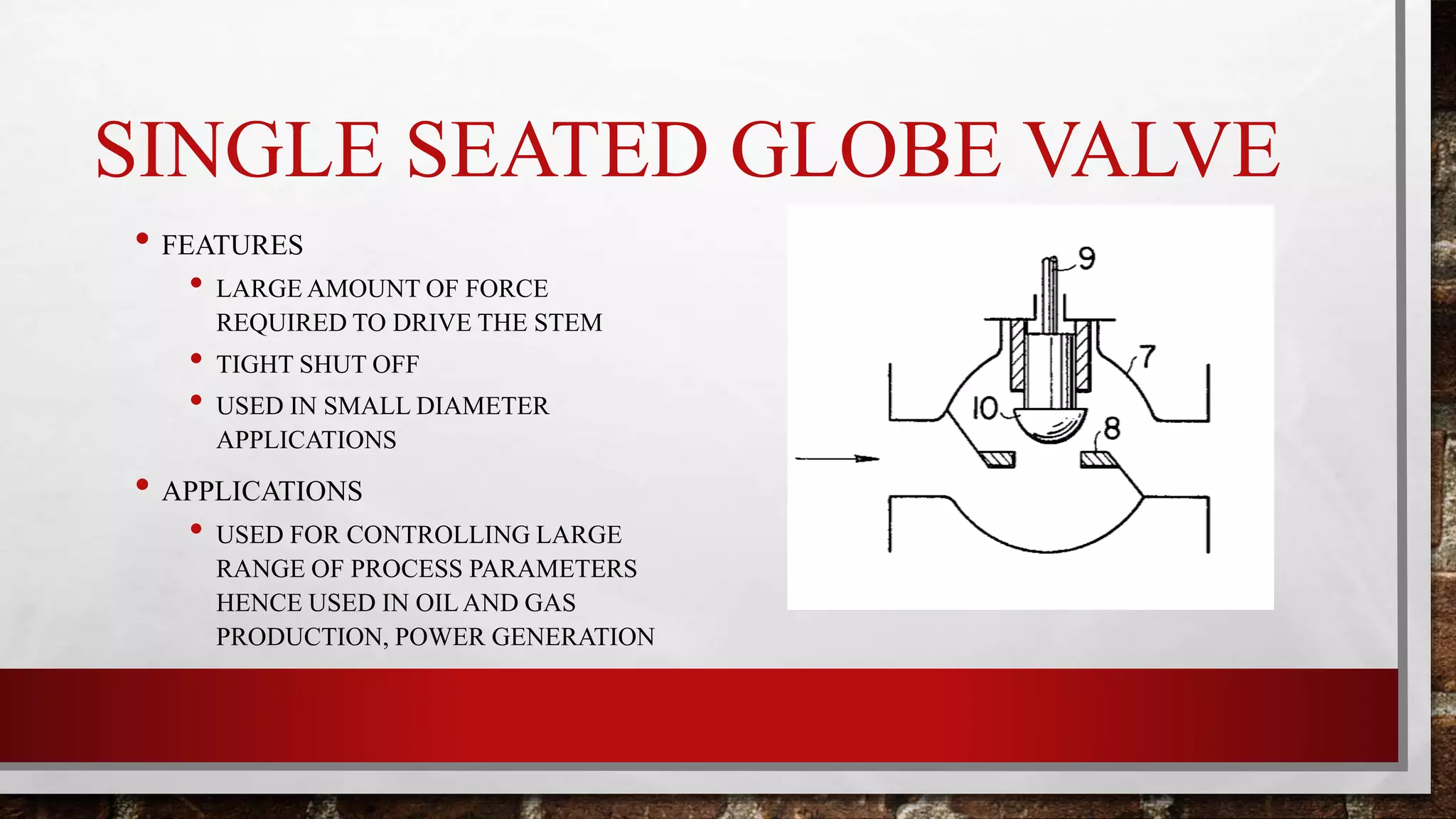

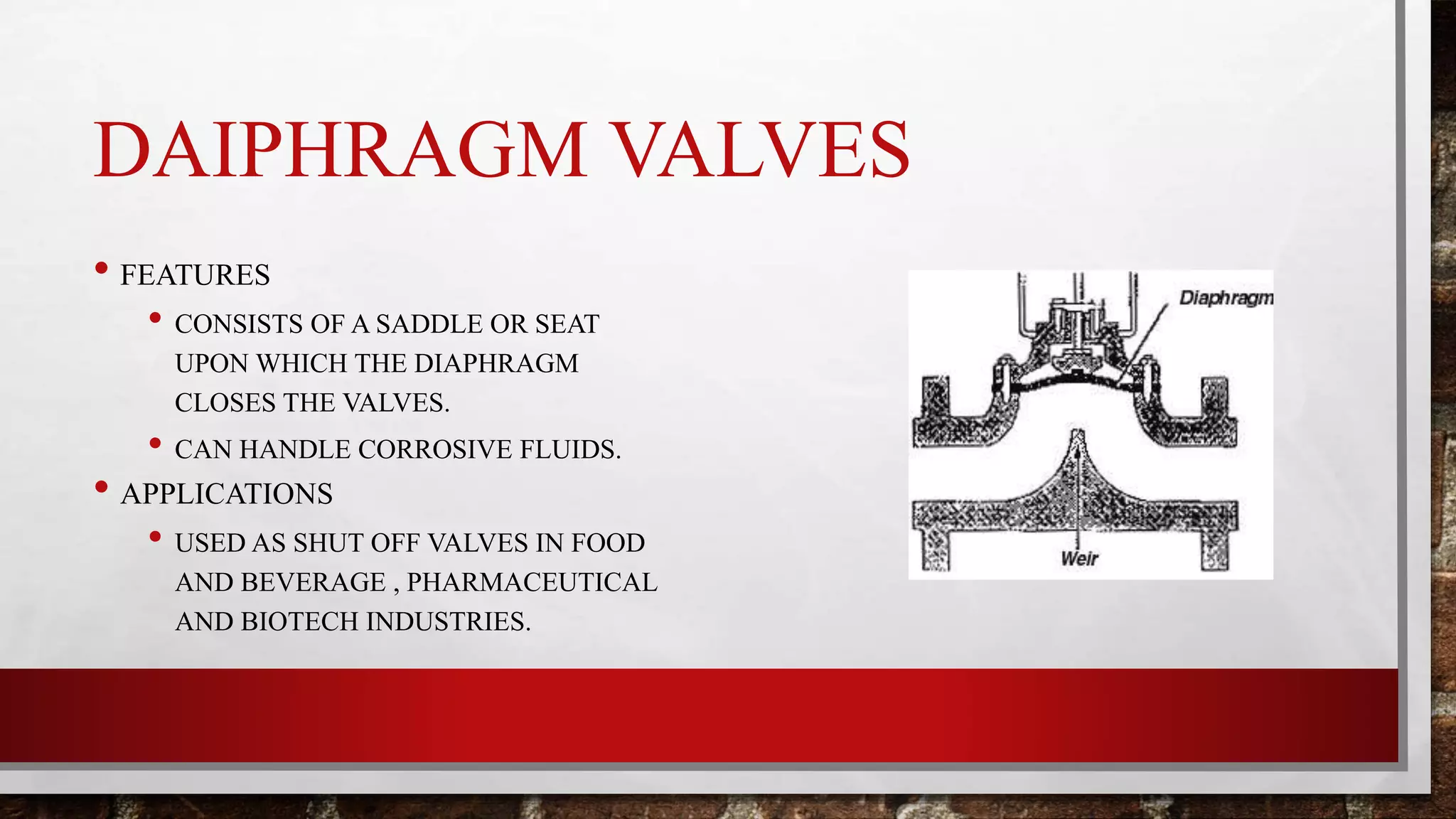

The document discusses control valves, including their purpose, main components, types of actuators (pneumatic, hydraulic, electrical), and types of valves (linear motion like globe valves and rotary motion like ball valves). It provides details on parts of control valves like the actuator, positioner, and body. It also covers topics like valve sizing, flow characteristics, and considerations for control valves like fluid velocity, noise, vibration, and flow direction.