Climate control products from Rittal provide concise summaries of key information from technical documents. The summary of the given document is:

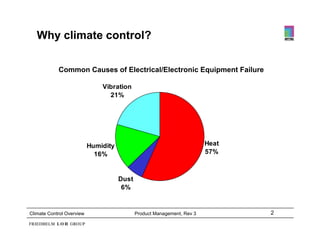

[1] Climate control products help control temperature, humidity, dust and vibration inside enclosures to improve reliability of electrical and electronic equipment.

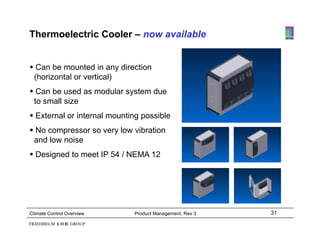

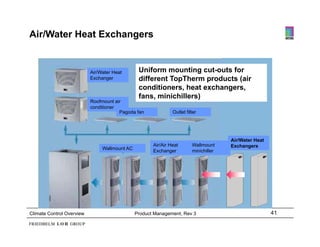

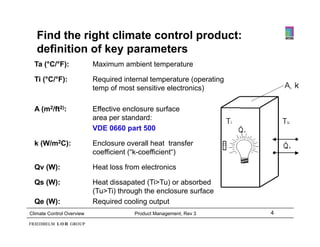

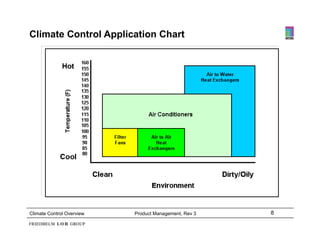

[2] Rittal offers a range of climate control products including air conditioners, filter fans, panel heaters and heat exchangers to maintain optimal internal enclosure temperatures.

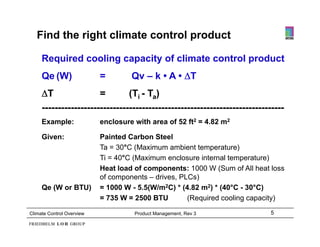

[3] Rittal's sizing software helps select the right climate control product by calculating heat loads, temperature differences and required cooling capacity.

![Why climate control?

Reduction of the service life according to Arrhenius' law

• Components generate heat

(

(heat loss Qv) )

Integrated

• Service life of components is circuits

reduced when temperature is too high

ars]

• Examples include:

Lifetime [yea

Electrol.

Transformers condenser

Controls

Frequency converters

L

Servers and network technology

Electrolytic capacitors

Component temperature [°C]

The challenge:

A growing number of products needs climate control

Energy demand

Climate Control Overview Product Management, Rev 3 3](https://image.slidesharecdn.com/enclosureclimatecontrol-100616093438-phpapp01/85/Enclosure-climatecontrol-3-320.jpg)

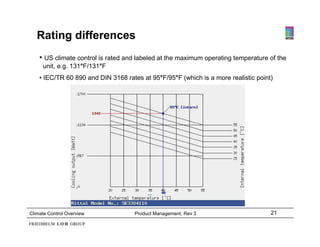

![Rating of Air Conditioners

Cooling

performance

Internal

[W or BTU] temperature

Qk °C

Ti

Ta

Ambient temperature ºC

C

Climate Control Overview Product Management, Rev 3 20](https://image.slidesharecdn.com/enclosureclimatecontrol-100616093438-phpapp01/85/Enclosure-climatecontrol-20-320.jpg)