This presentation discusses the latest sensor trends from Balluff, including:

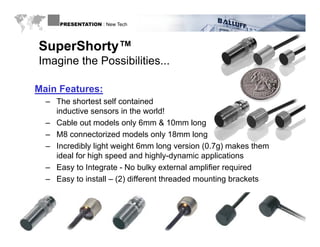

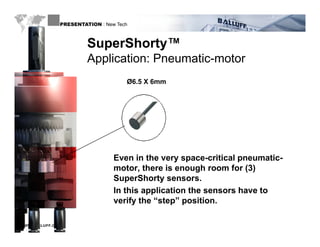

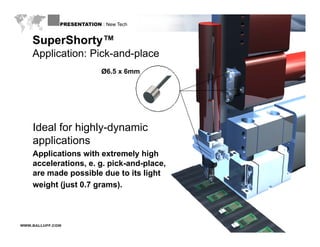

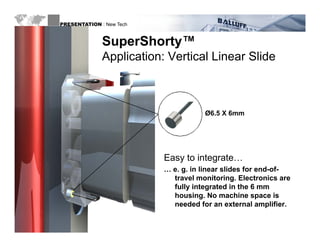

1) Their smallest inductive sensors yet, the SuperShorty sensors, which enable new applications due to their miniature size.

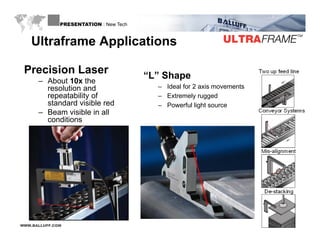

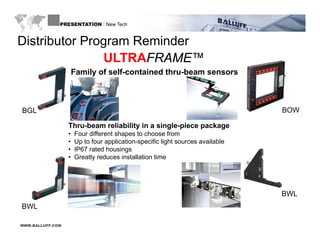

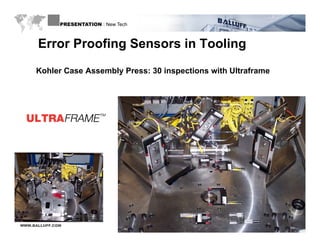

2) Alternatives to fiber optic sensors, such as their Ultraframe sensors, which provide more reliable detection for applications like feed systems.

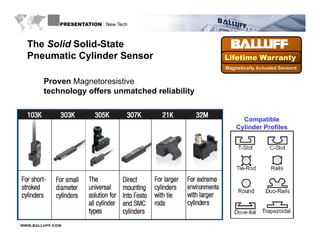

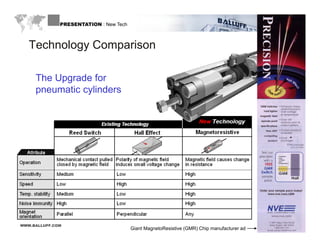

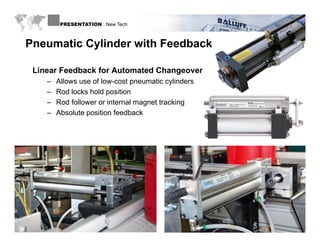

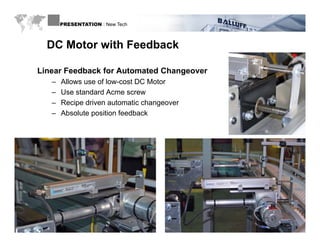

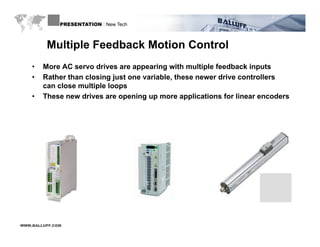

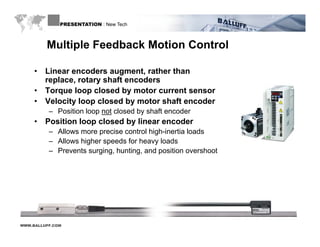

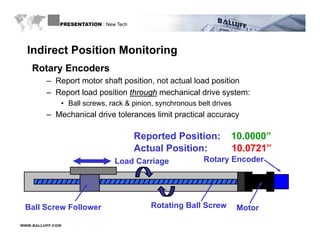

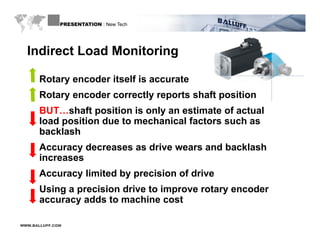

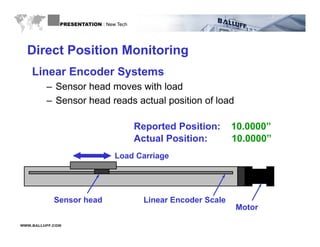

3) New technologies for sensing pneumatic cylinders and loads, including dual sensor systems, lifetime warranties, and direct load monitoring with linear encoders.

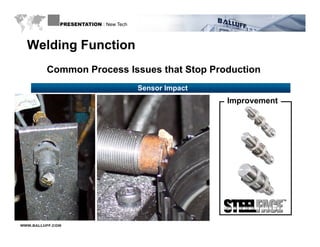

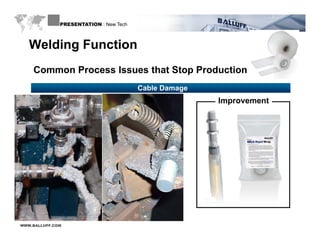

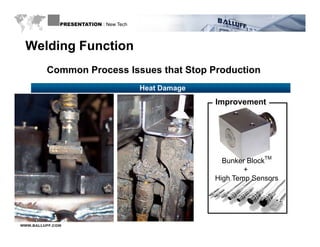

4) Methods to improve sensor survivability in harsh environments like welding through products like their Bunker Block housing and high temperature sensors.

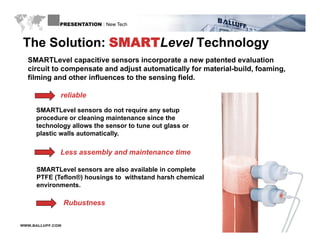

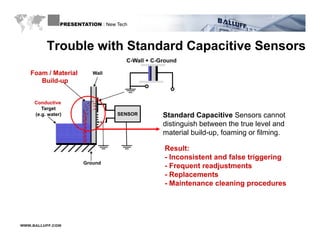

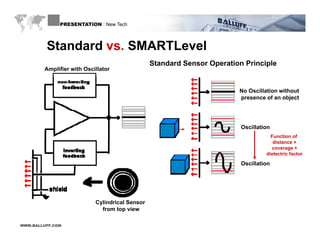

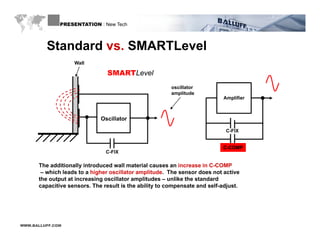

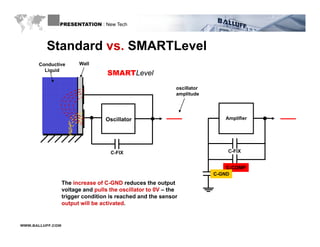

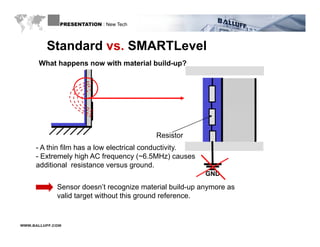

5) The new SmartLevel capacitive sensors which can auto-tune for difficult liquid