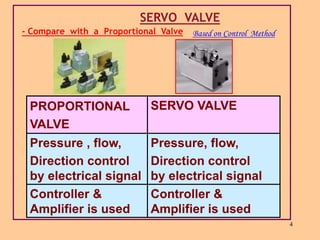

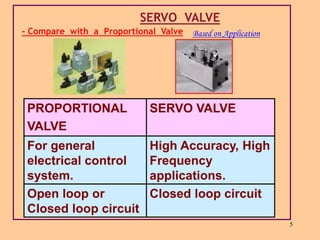

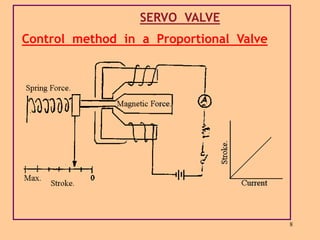

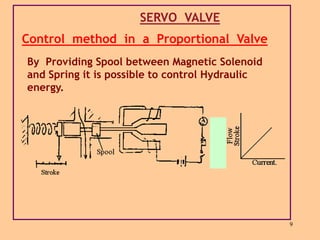

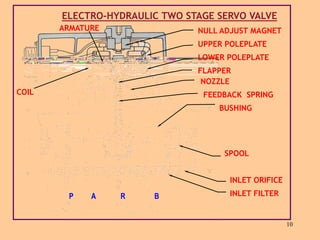

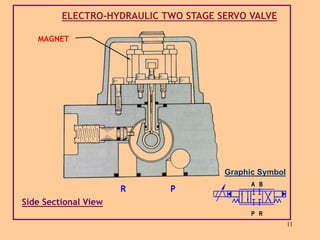

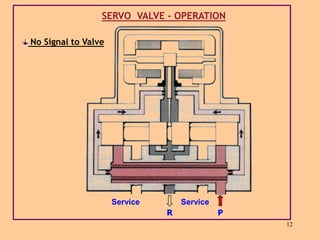

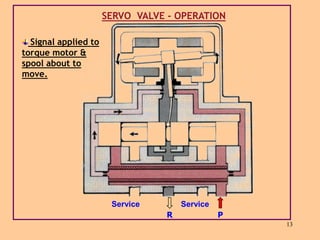

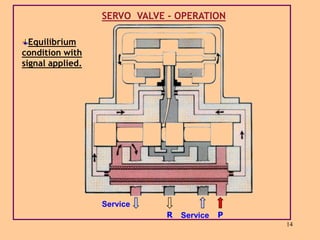

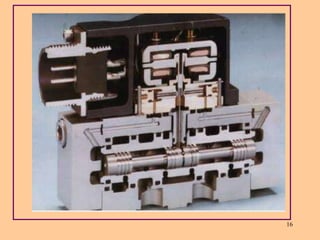

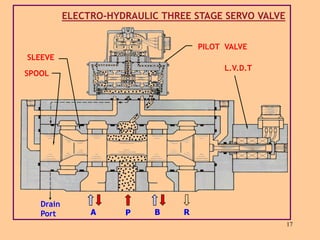

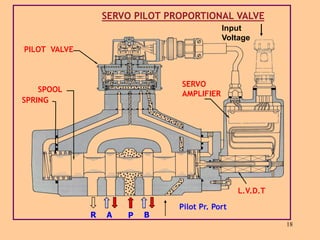

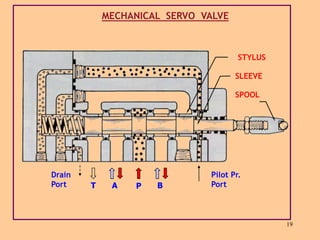

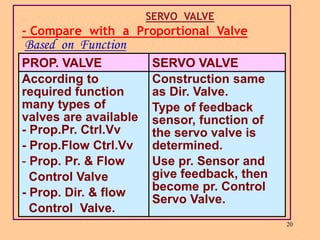

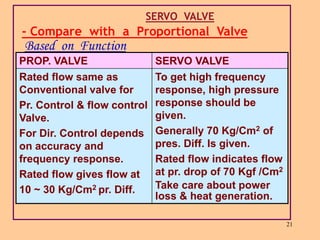

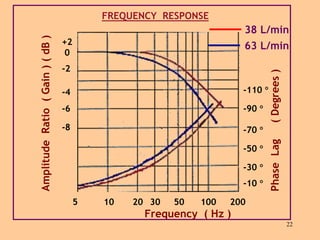

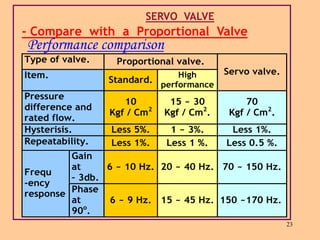

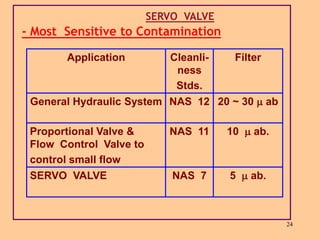

A servo valve is a directional control valve that can be precisely positioned using an electrical signal to control the amount and direction of fluid flow. Coupled with sensors, servo valves provide very accurate control of position, velocity, or acceleration. Compared to proportional valves, servo valves use closed-loop control for higher accuracy and frequency response but require cleaner fluid and more maintenance. Servo valves are the most sensitive to contamination and require fluid cleanliness of 5 microns or less.