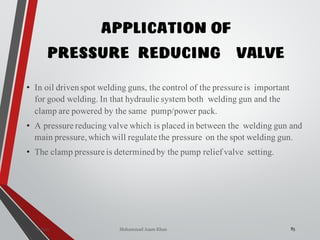

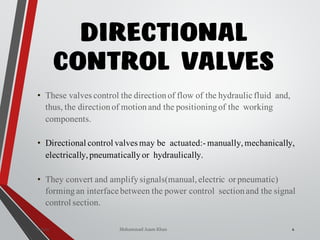

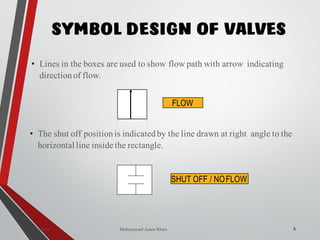

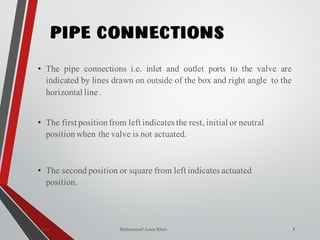

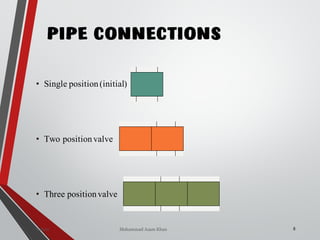

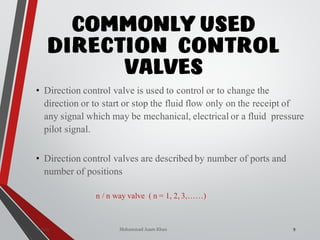

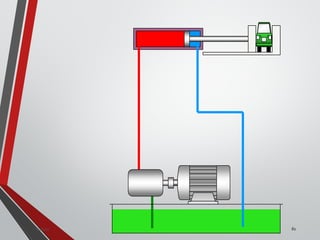

The document provides an overview of hydraulic valves, detailing their functions, types, and operational principles. It specifically covers directional control valves, symbol designations, connection configurations, and various kinds of valves including pressure control and non-return valves. Additionally, it explains flow rate control and the applications of pressure relief and reducing valves in hydraulic systems.

![Mohammad Azam Khan [M.Tech- Industrial and Production]

HYDRAULIC

1Valves

VALVES](https://image.slidesharecdn.com/07hydraulicvalves-180612224109/75/Hydraulic-Valves-Valves-Pneumatics-also-1-2048.jpg)

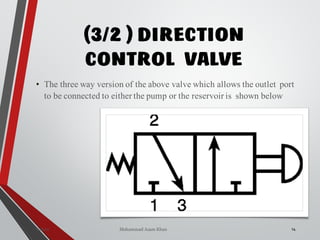

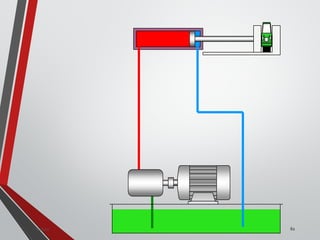

![WAY/POSITION

10

Way Valve Ports Positions

2/2

3/2

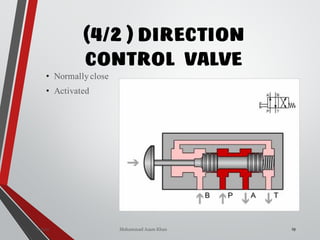

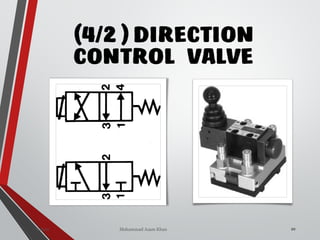

4/2

4/3

2.(1 inputs, 1 output) 2

3.(1 input, 1 output, 1 tank) 2

4.(1 input,2 output, 1 tank) 2

4 (1 input, 2 output, 1 tank) 3

Mechatronics]

Valves Sanjay Humania[M.Tech-](https://image.slidesharecdn.com/07hydraulicvalves-180612224109/85/Hydraulic-Valves-Valves-Pneumatics-also-10-320.jpg)

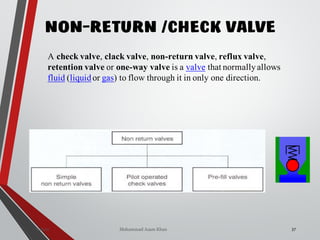

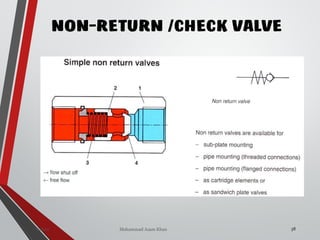

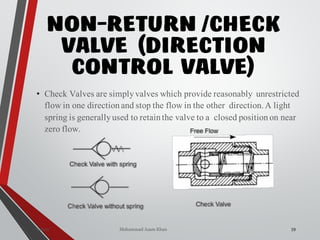

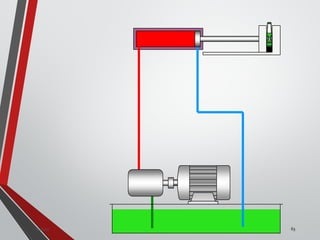

![NON-RETURN /CHECK

VALVE (DIRECTION

CONTROL VALVE)

ania [M.Tech- Mechatronics] 155Valves SanjayHum](https://image.slidesharecdn.com/07hydraulicvalves-180612224109/85/Hydraulic-Valves-Valves-Pneumatics-also-40-320.jpg)

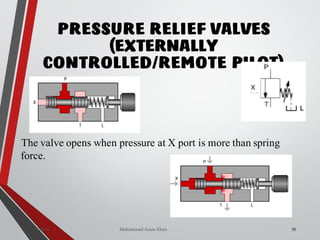

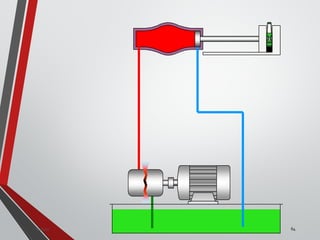

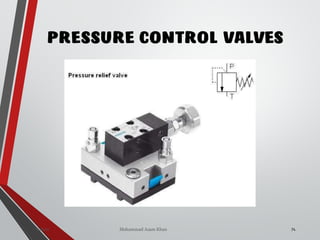

![PRESSURE RELIEF VALVES

75

• Relief valves are generallyspring loaded valves which include a plug

over a discharge port which is liftedagainst an spring force if the

system pressure exceeds a certainvalue. This opens the flow to the

discharge port relieving the pressure.

Sanjay Humania [M.Tech- MechatronicsValves ]](https://image.slidesharecdn.com/07hydraulicvalves-180612224109/85/Hydraulic-Valves-Valves-Pneumatics-also-75-320.jpg)