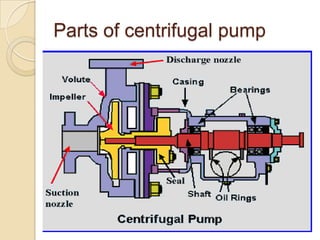

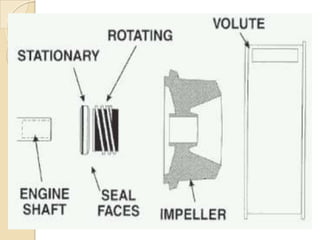

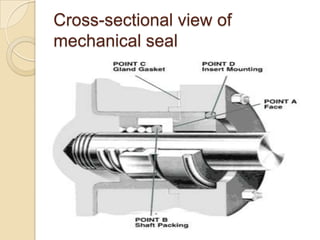

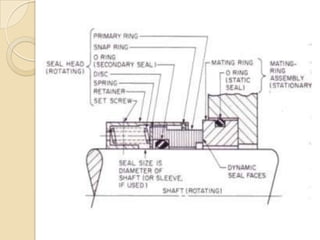

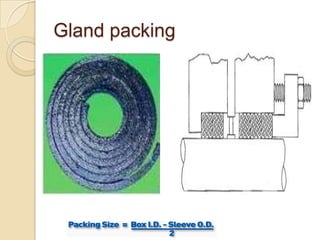

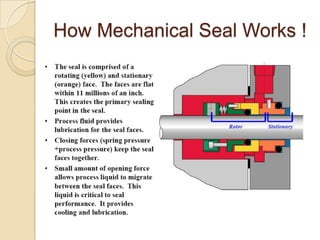

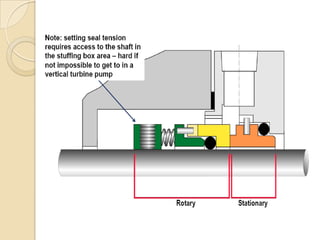

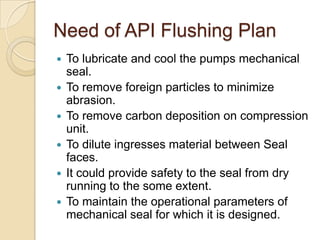

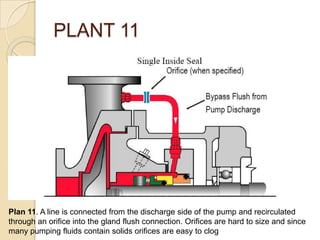

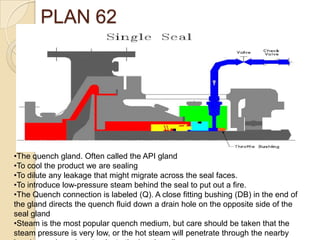

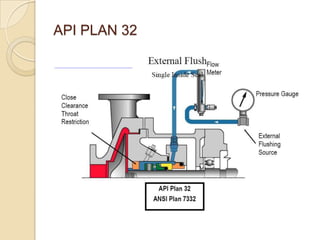

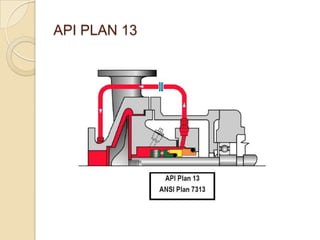

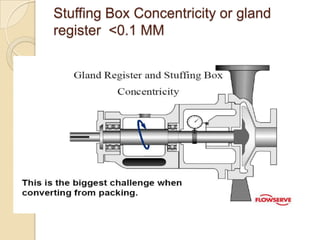

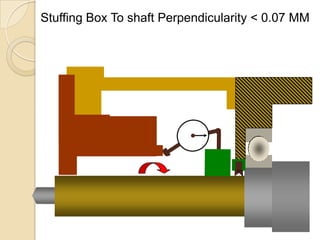

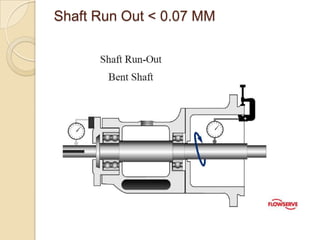

Mechanical seals are key components in centrifugal pumps that prevent fluid from leaking out of the pump casing. They consist of two faces, one stationary and one rotating, located between the impeller and rear casing. Pumps in harsh environments require more abrasion-resistant seals than regular pumps. Mechanical seals reduce leakage compared to gland packings, saving power. Proper flushing plans are needed to lubricate, cool, and clean the seal while removing particles to minimize abrasion and extend seal life. Common operational and maintenance errors that reduce seal life include dry running, suction choking, foreign materials, improper flushing plans, misalignment, stuffing box issues, and failed bearings.