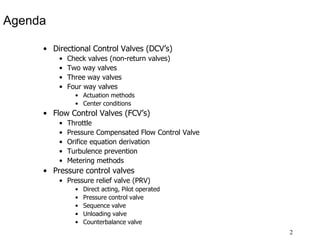

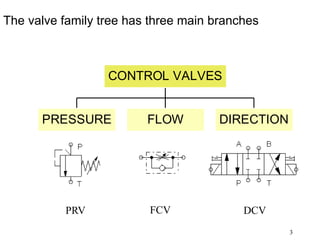

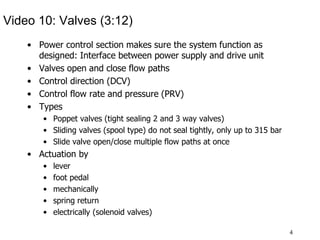

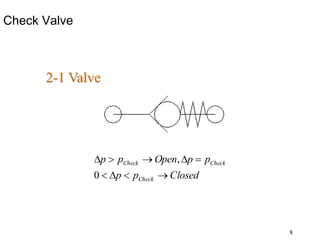

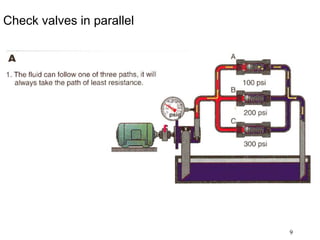

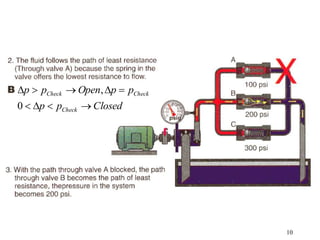

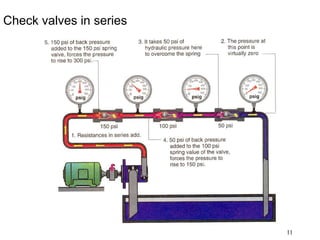

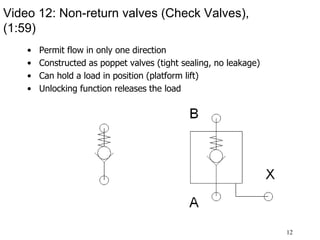

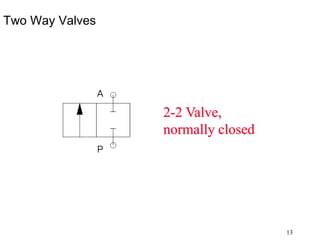

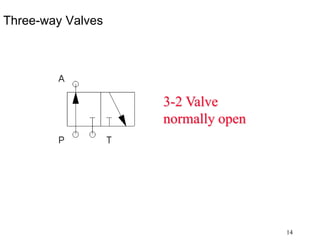

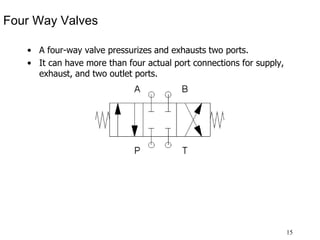

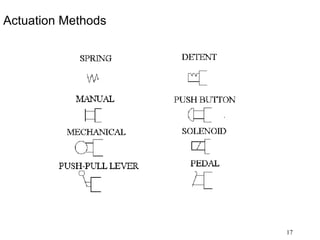

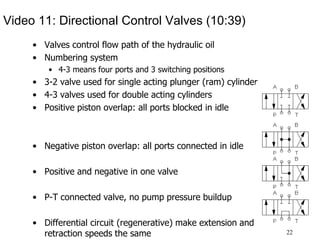

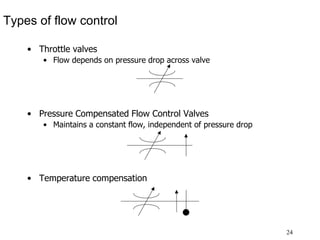

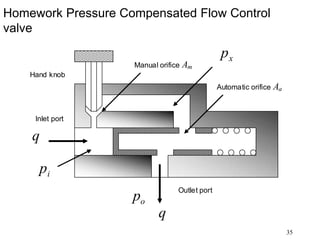

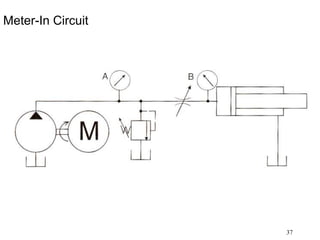

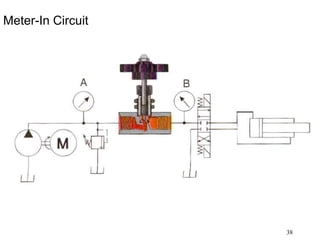

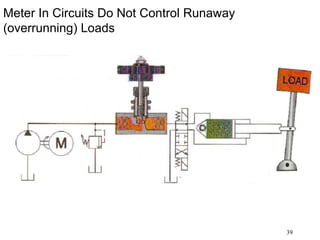

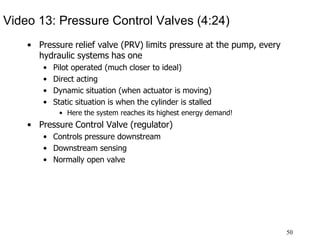

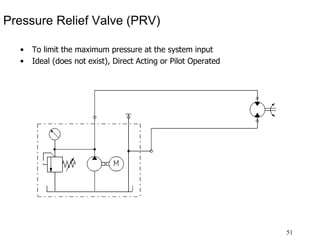

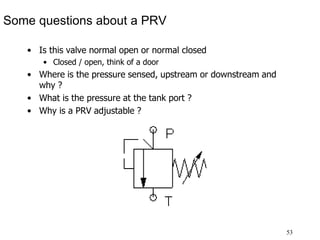

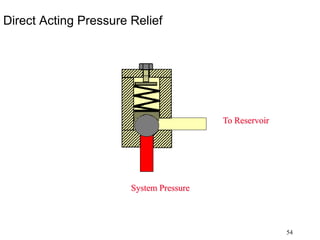

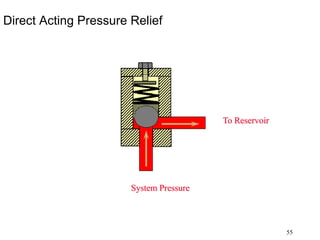

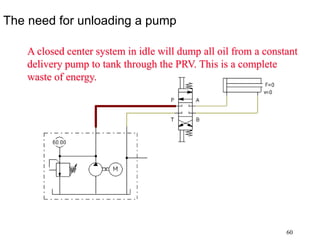

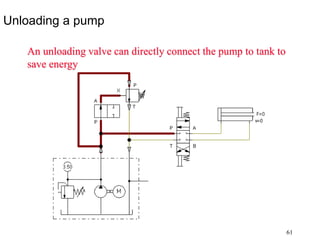

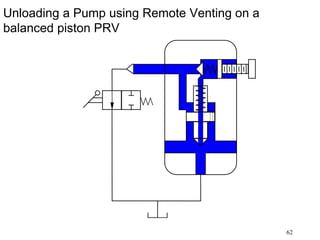

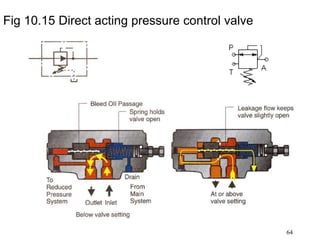

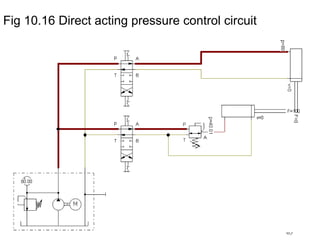

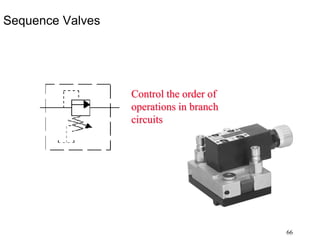

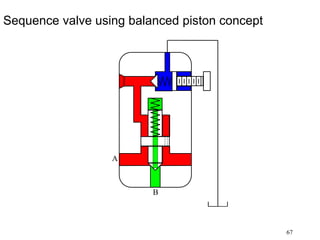

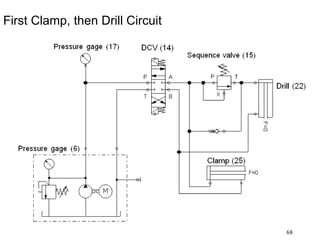

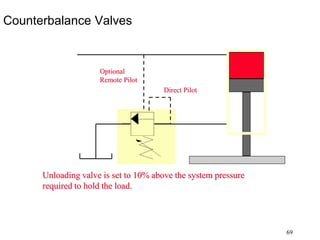

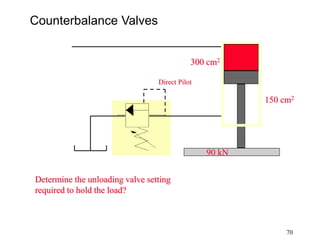

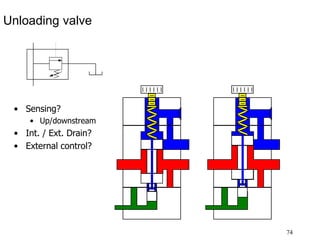

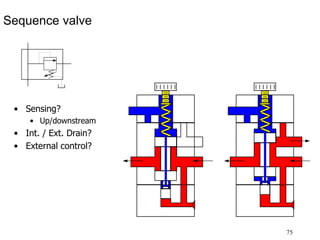

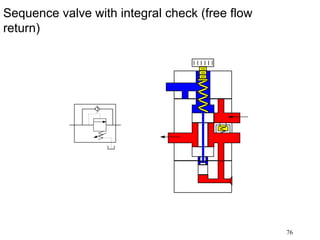

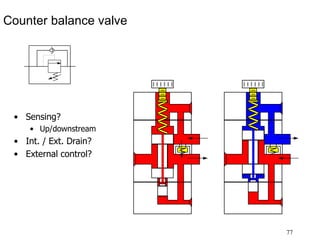

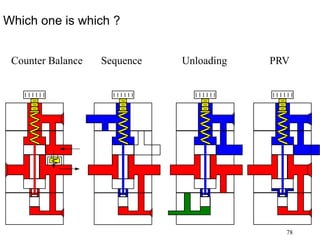

This document provides an overview of different types of valves used in fluid power systems. It discusses directional control valves like check valves, two-way valves, and three-way valves. It also covers flow control valves, pressure control valves, and sequence valves. Directional control valves are used to control the direction of flow, while flow control valves regulate flow rate and pressure control valves are used to limit or reduce pressure in the system. Sequence valves control the order of operations in hydraulic circuits.