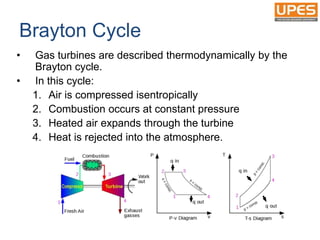

Gas turbines are internal combustion engines that produce power by burning an air-fuel mixture to spin a turbine and drive a generator. They work by compressing air, igniting the air-fuel mixture at high temperatures, spinning turbine blades with the hot gases, and using the spinning turbine to power a generator and produce electricity. Gas turbines can operate on a wide range of gaseous, liquid, and solid fuels. Fuel injectors introduce fuel into the combustion chamber in atomized form. Emissions like CO, NOx, and UHC are controlled through techniques like optimized fuel-air ratios, improved mixing, and exhaust gas recirculation. CFD analysis is used to study internal cooling schemes in turbine blades.

![Emissions :

Different types of emissions are CO, NO and UHC.

1. CO [Carbon monoxide]

Causes:

CO is produced in all fuel/air ratios.

At low temperatures, that corresponding to low fuel/air ratios (Φpz < 0.5),

CO cannot be burnt to CO2.

At high temperatures or high fuel/air ratios (Φpz > 0.9) on the other hand,

CO2 dissociates to CO.

Reduction:

Improved fuel atomization.

Holding the primary-zone equivalence ratio to its optimum value by

redistributing the air flow.

Increase the residence time or the primary’s zone volume.

Use of fuel staging.

Use of compressed air-bleed.](https://image.slidesharecdn.com/gasturbinesppt500057847-copy-180324065117/85/Gas-turbines-14-320.jpg)

![2. UHC [Unburnt Hydrocarbons]

The parameters that influence CO emissions are also affecting

UHC emissions in the same way. So, UHC emissions reduction

requires the same treatment with CO emissions, but more attention

should be paid on the “reduction of film-cooling air” in the primary zone,

as well as on fuel atomization improvements. The latter could be

achieved with the use of airblast atomizers and air assist nozzles.

3. NO [Oxides of Nitrogen]

The principal parameter that governs NOx formation is temperature.

Reduction:

Lean primary zone.

Rich primary zone.

Improved combustion’s homogeneity

Use of water injection

Recirculation of exhaust gas.](https://image.slidesharecdn.com/gasturbinesppt500057847-copy-180324065117/85/Gas-turbines-15-320.jpg)