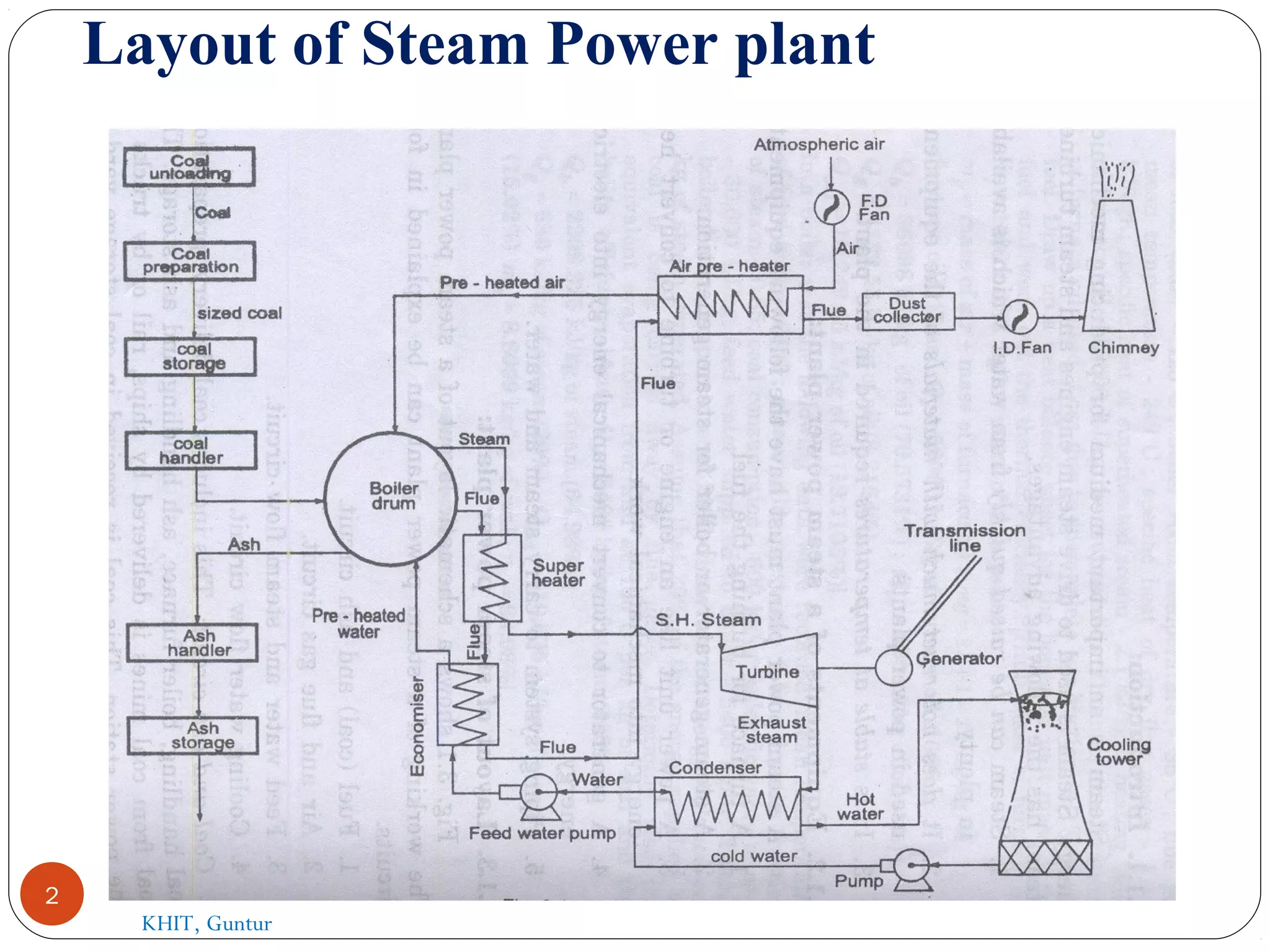

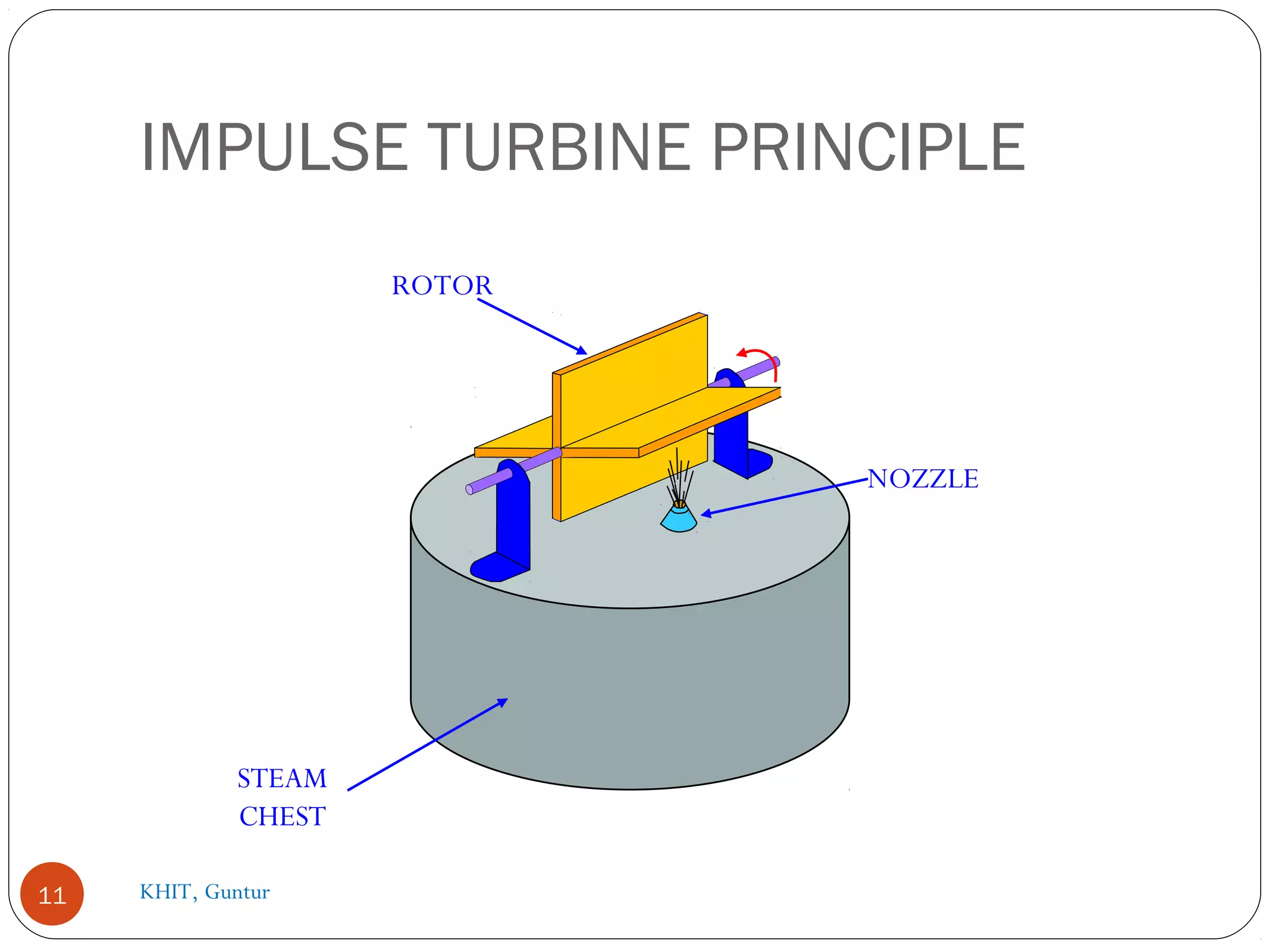

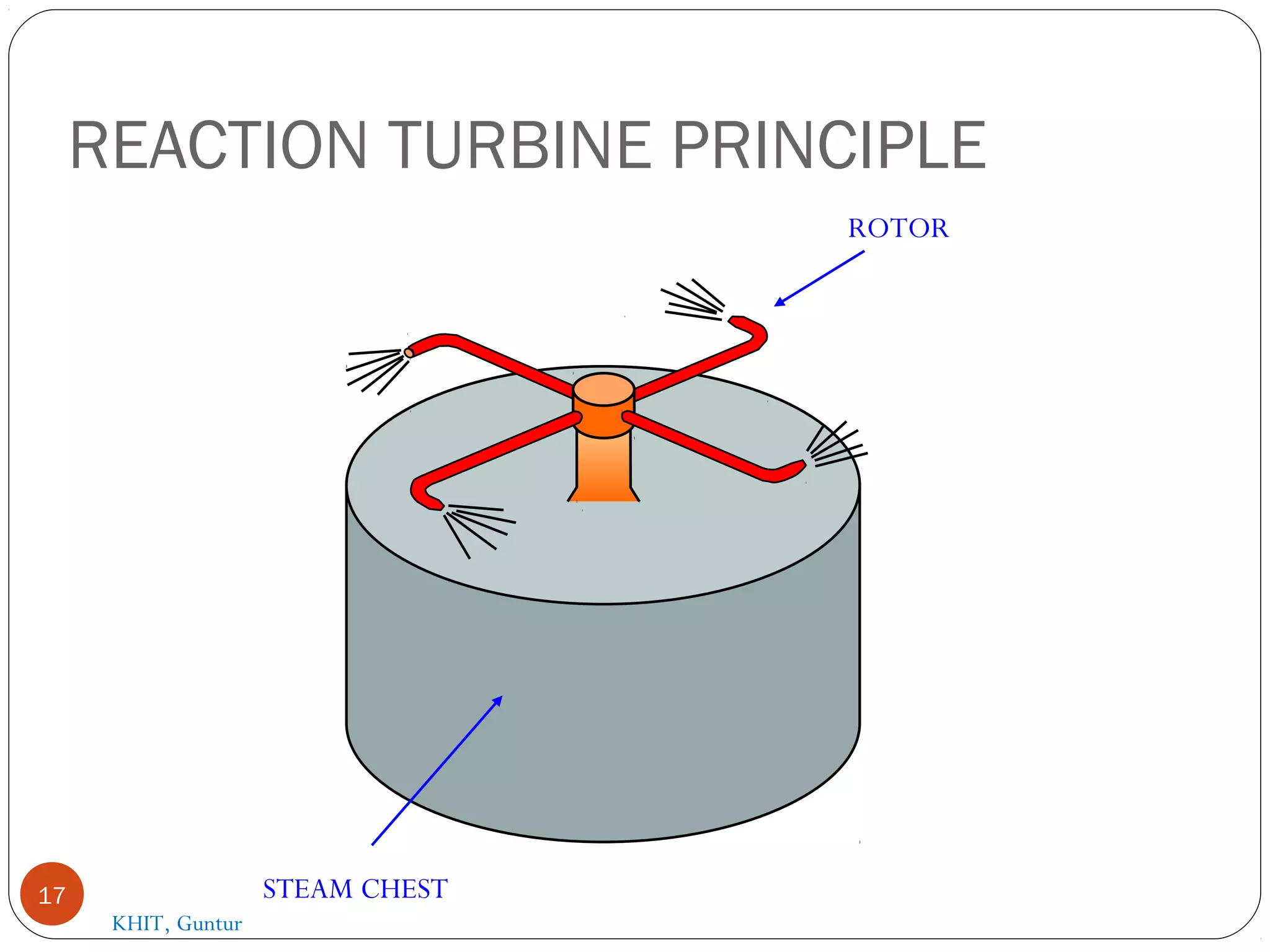

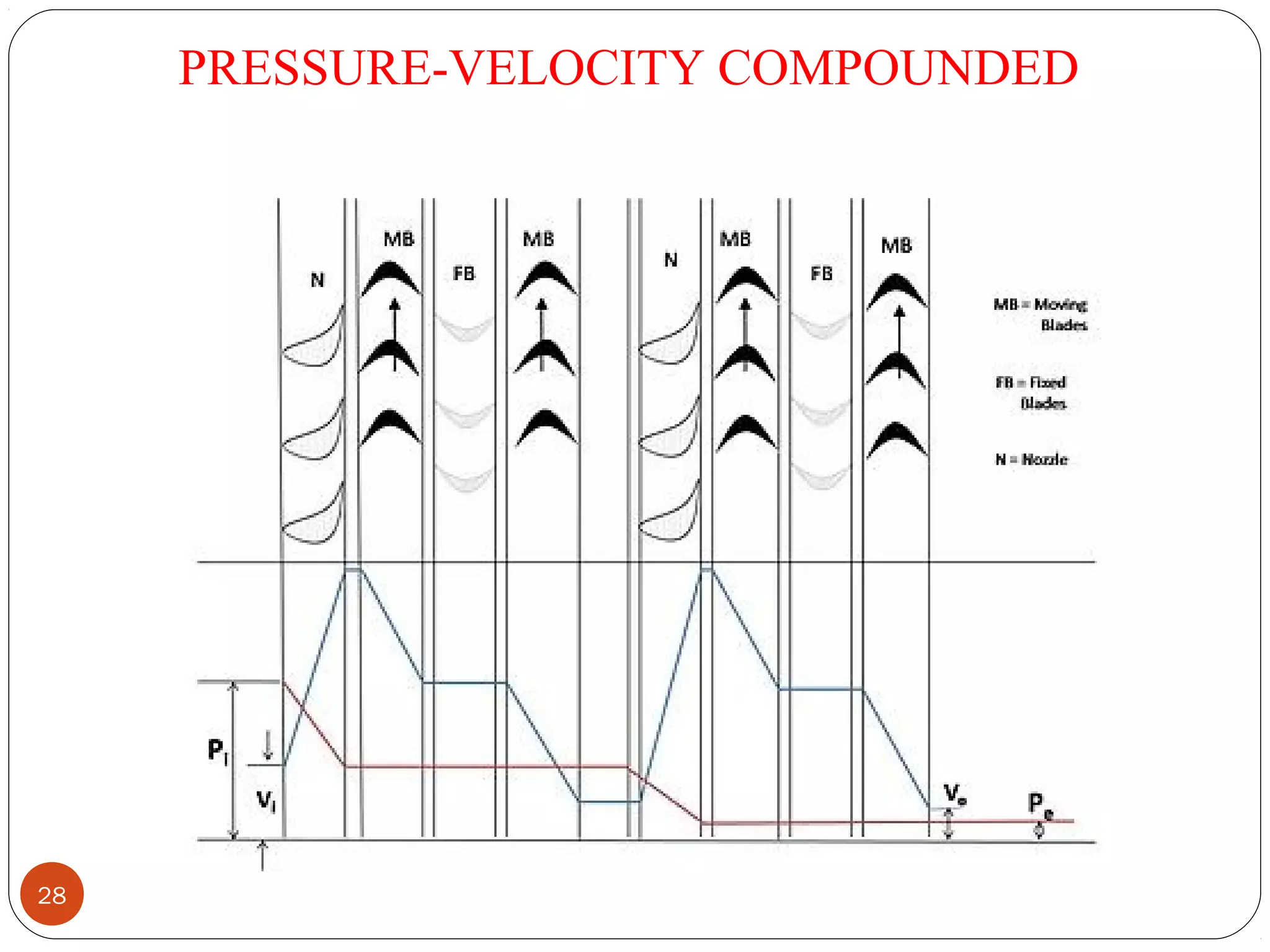

This document discusses steam turbines, including their working principles and different types. It describes how potential energy from steam is converted to kinetic energy and then mechanical energy in a turbine. There are two main types of turbines - impulse turbines and reaction turbines. Impulse turbines expand steam fully in nozzles before it hits moving blades, while reaction turbines feature continuous expansion over fixed and moving blades. The document also discusses methods of compounding turbines to reduce rotor speed, including velocity, pressure, and pressure-velocity compounding.