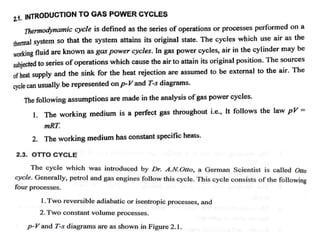

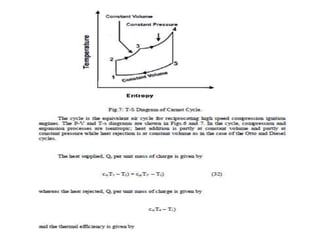

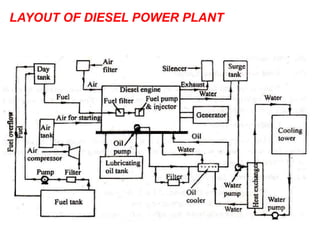

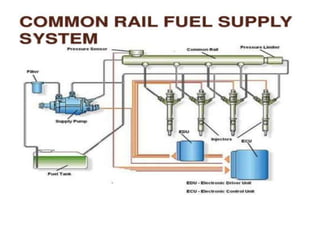

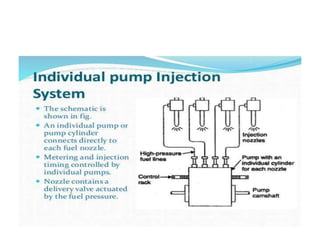

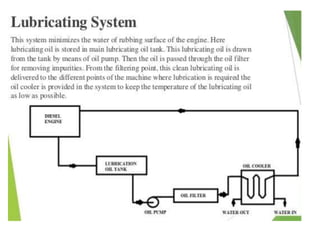

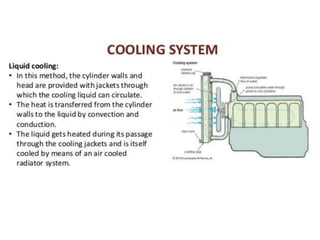

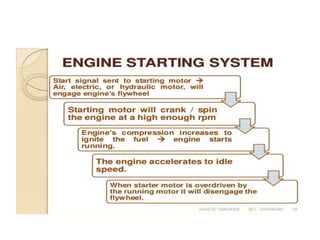

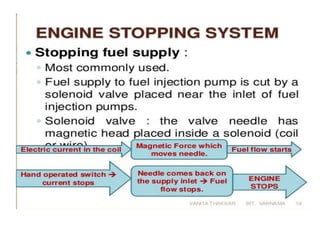

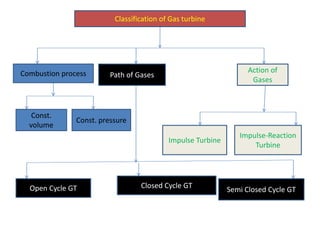

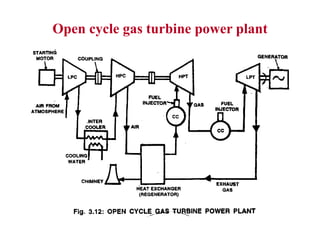

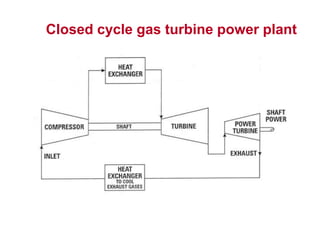

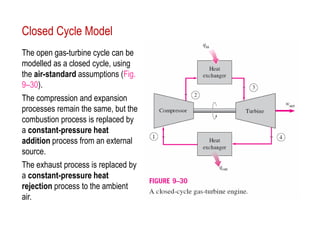

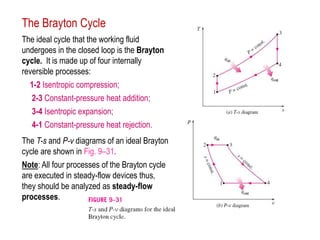

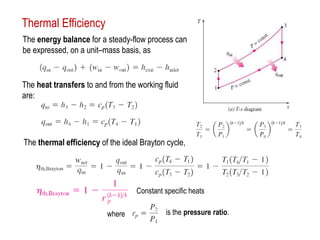

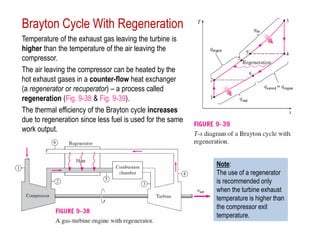

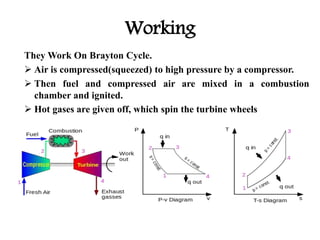

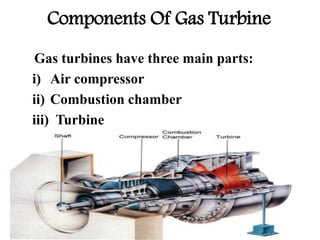

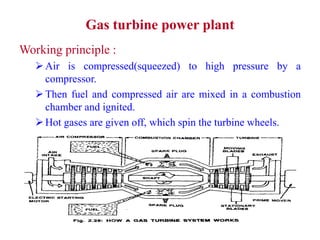

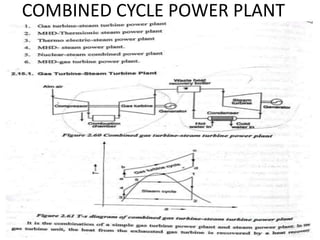

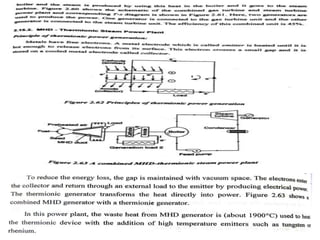

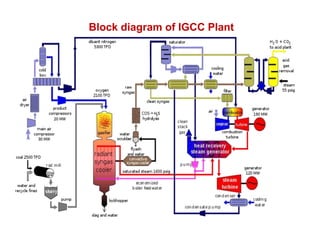

The document discusses diesel, gas turbine, and combined cycle power plants. It provides details on the layout and components of a diesel power plant, including the engine, air supply system, exhaust system, fuel system, cooling system, lubricating system, and starting system. It also discusses advantages like efficiency and disadvantages like noise pollution of diesel power plants. Open and closed cycle gas turbine power plants are compared, with open cycle plants having less weight but lower part-load efficiency. The ideal gas turbine cycle is the Brayton cycle of 4 processes - isentropic compression, constant pressure heat addition, isentropic expansion, and constant pressure heat rejection.