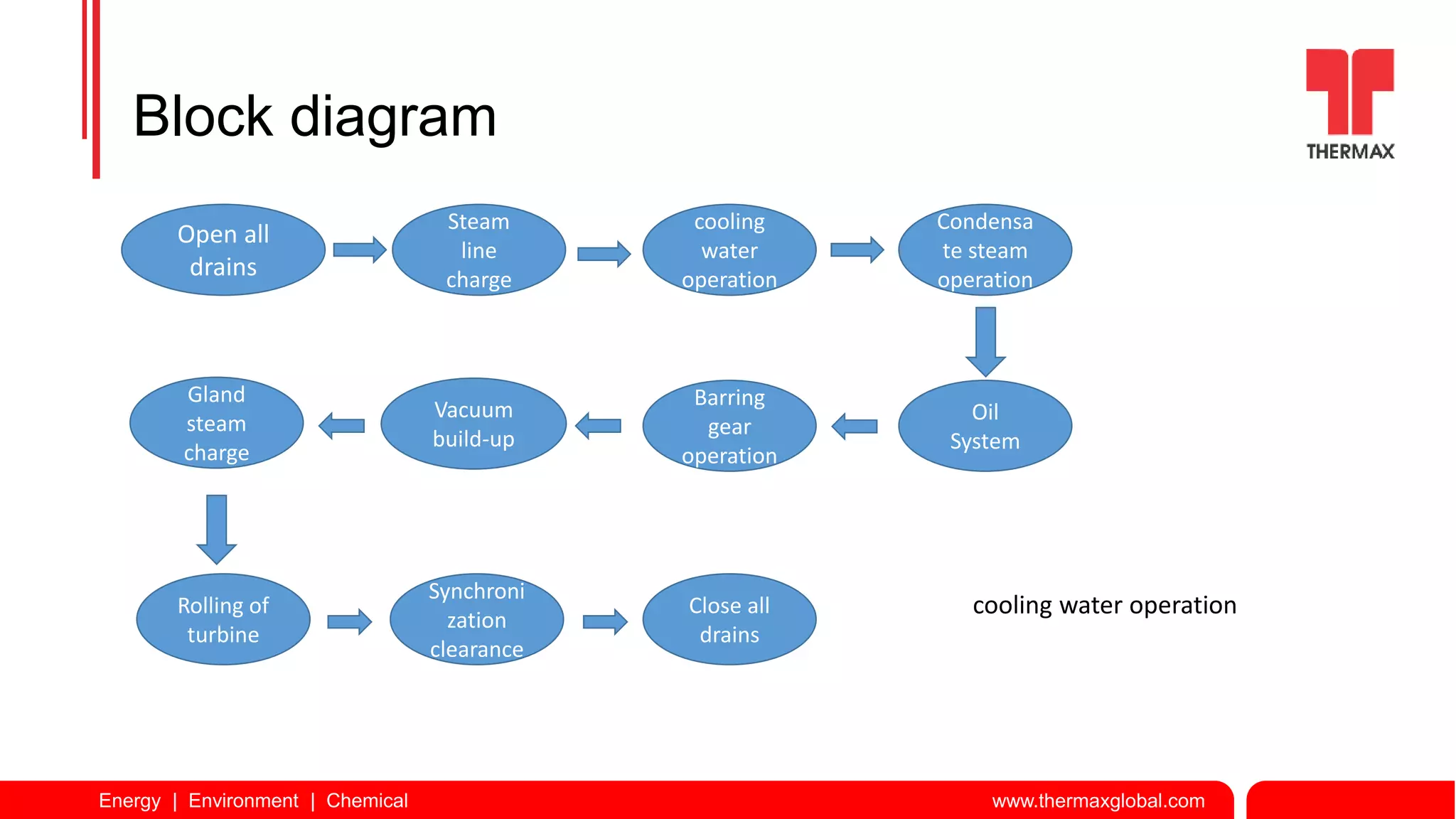

This document provides instructions for starting up a steam turbine. It outlines the sequence of operations that must be followed, including: opening drains, charging the steam line, starting the cooling water system, operating the condensate system, starting the oil system, putting the turbine on barring, building vacuum, charging gland steam, rolling the turbine, and synchronizing once full speed is reached. Special attention is given to ensuring auxiliary systems are operational and parameters are within limits at each stage to safely start the turbine.