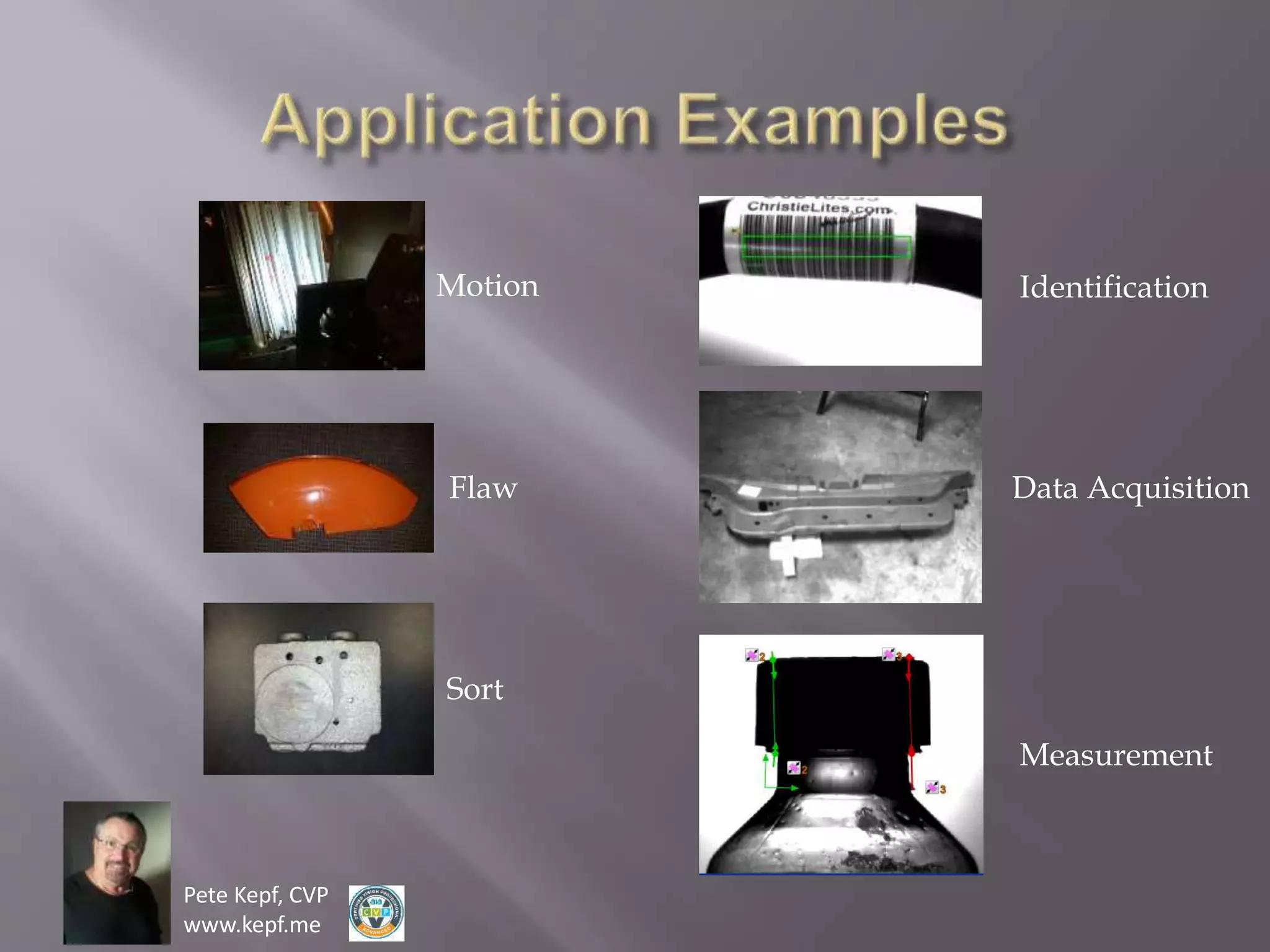

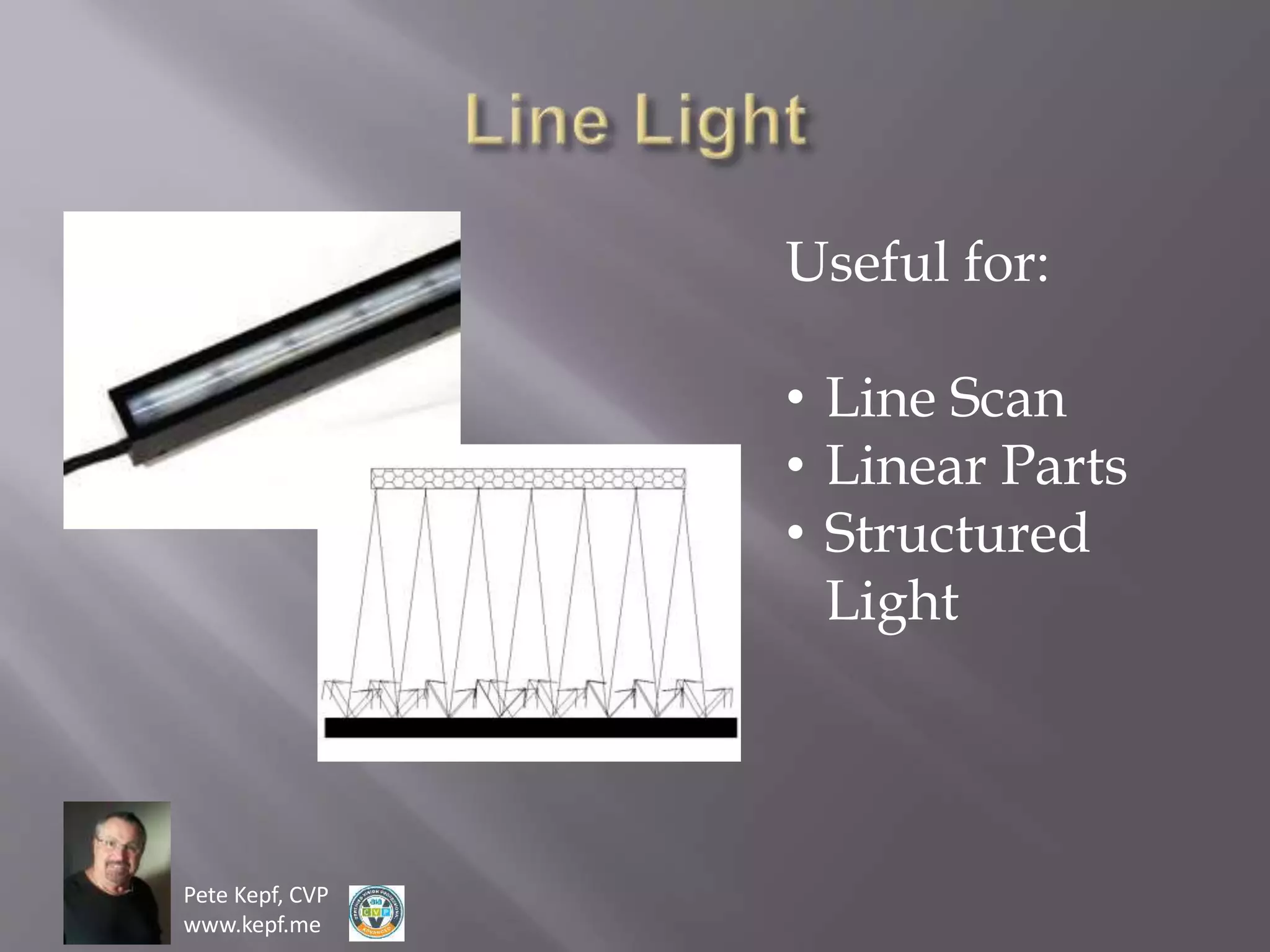

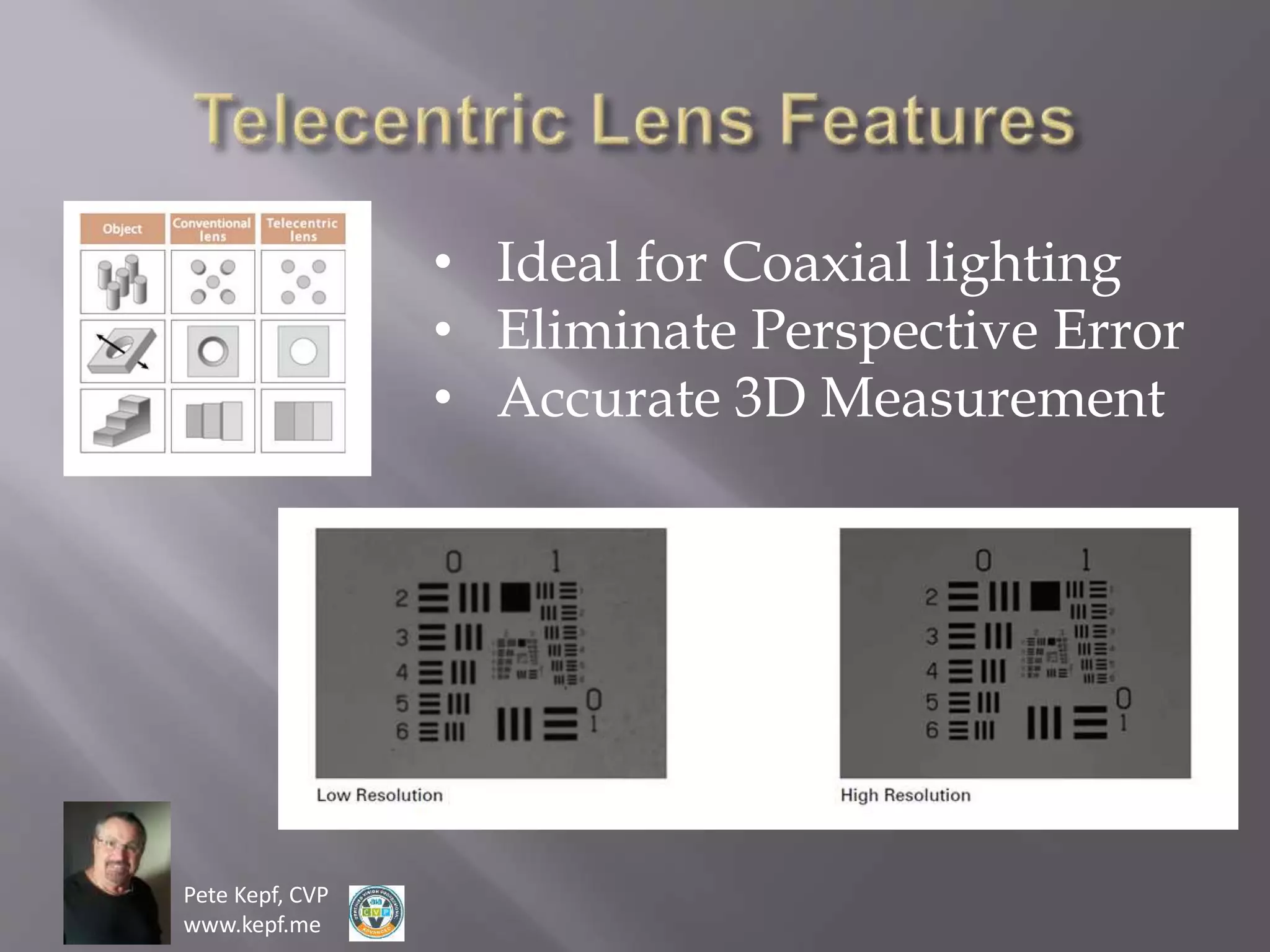

The document provides an overview of machine vision and its components. It discusses the top five industrial users of machine vision, common machine vision applications, and key components like lenses, cameras, lighting, and software tools. It also outlines steps for selecting a machine vision vendor, including defining requirements, researching technology options, evaluating solutions, and performing a risk assessment.