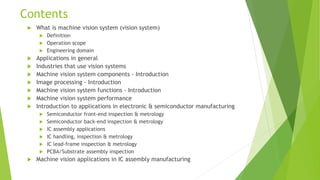

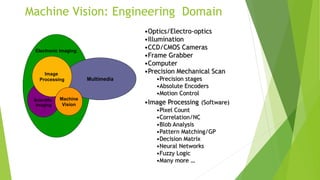

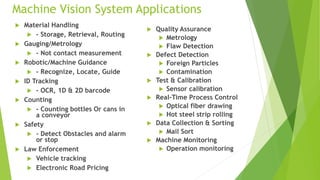

This document discusses machine vision systems and their applications in semiconductor manufacturing. It begins with definitions of machine vision systems and an overview of their components and functions. It then discusses various applications of machine vision in semiconductor front-end and back-end processes like inspection, metrology, and assembly. Specific applications mentioned include inspection of wafers, dies, packages, leads, and printed circuit boards. The document provides examples of machine vision aiding processes like die bonding, wire bonding, laser marking, and automated assembly.