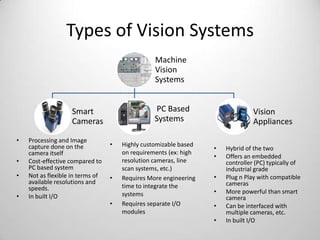

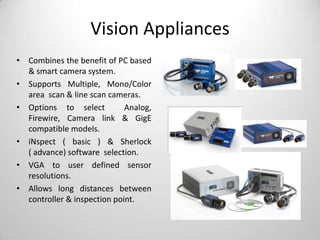

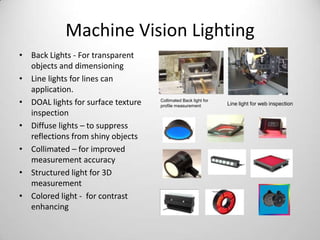

Qualitas Technologies specializes in software development for machine vision and industrial automation solutions, focusing on using digital imaging to enhance the inspection processes in manufacturing across various industries. Their offerings include a range of machine vision systems such as smart cameras, vision appliances, and digital cameras, alongside powerful vision inspection software to meet diverse operational needs. Qualitas serves a wide array of sectors, including automotive, aerospace, electronics, and pharmaceuticals, providing customizable solutions tailored to specific inspection requirements.