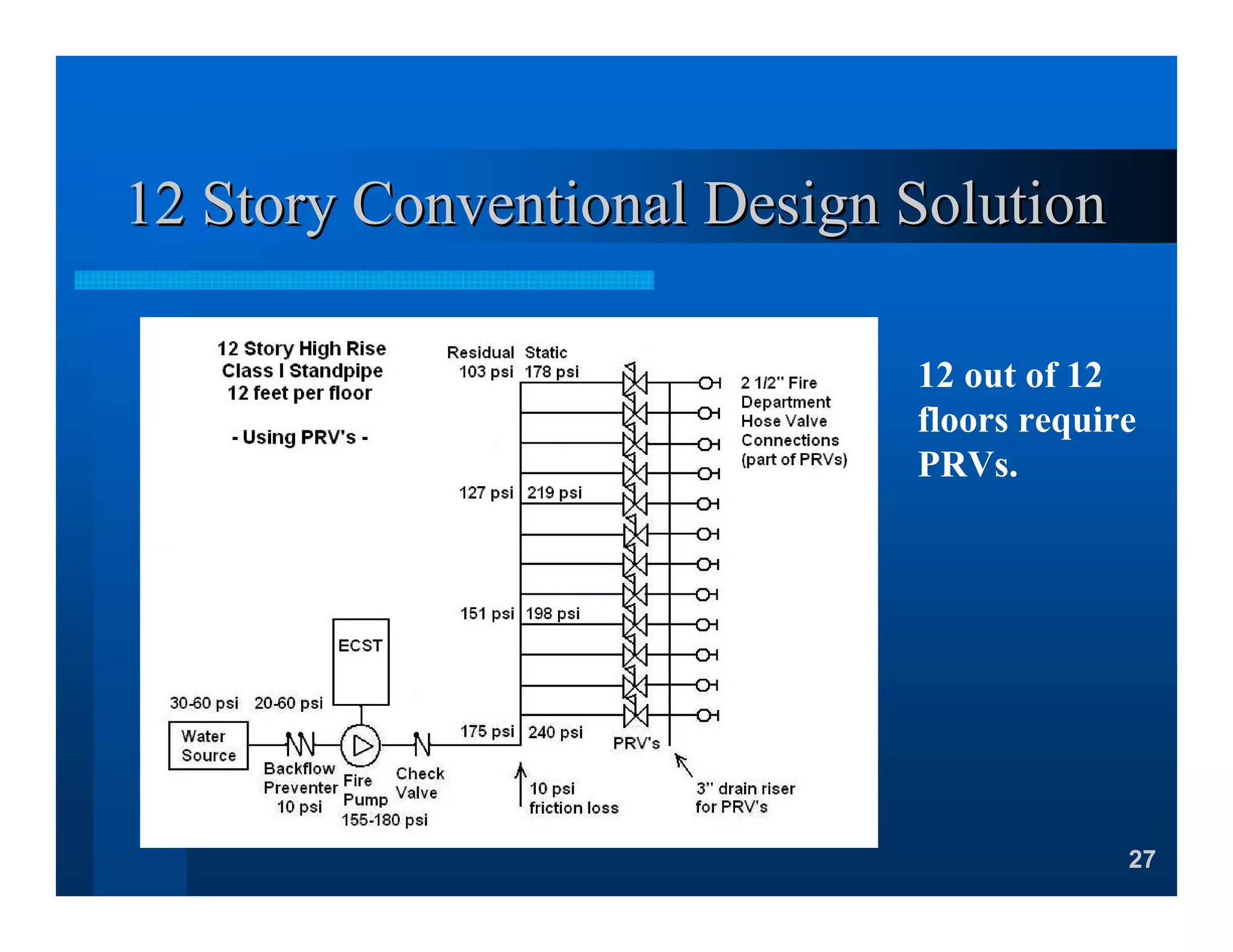

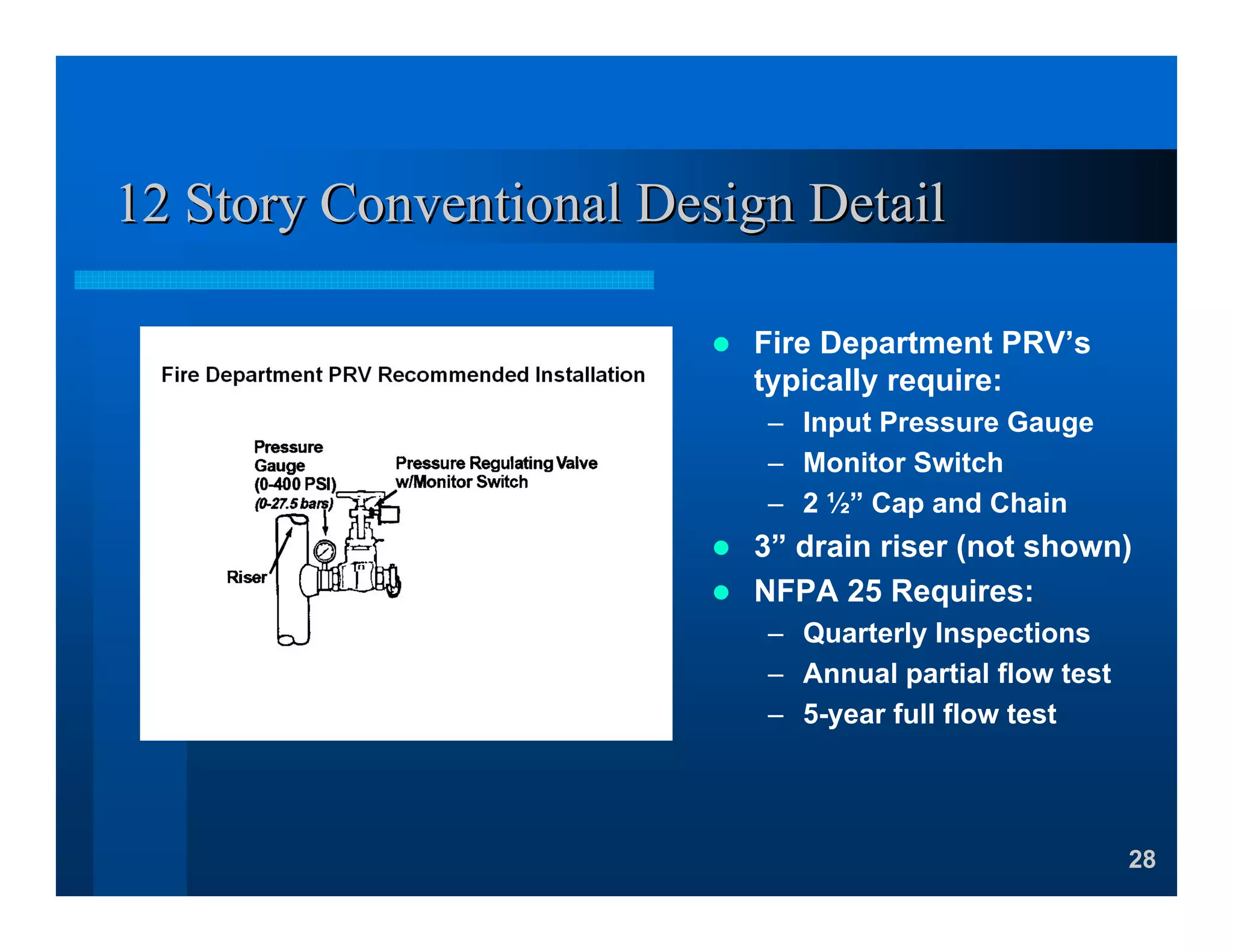

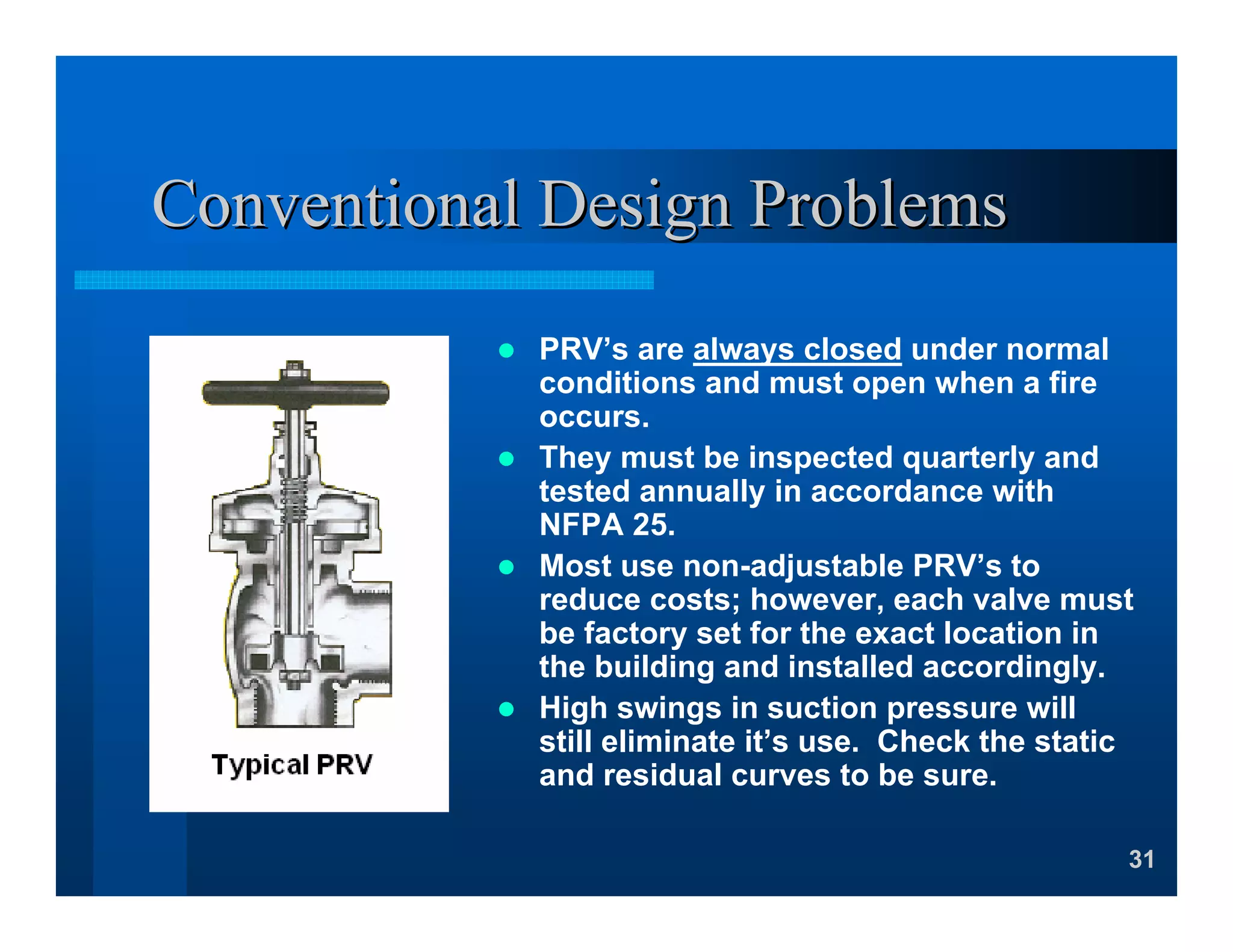

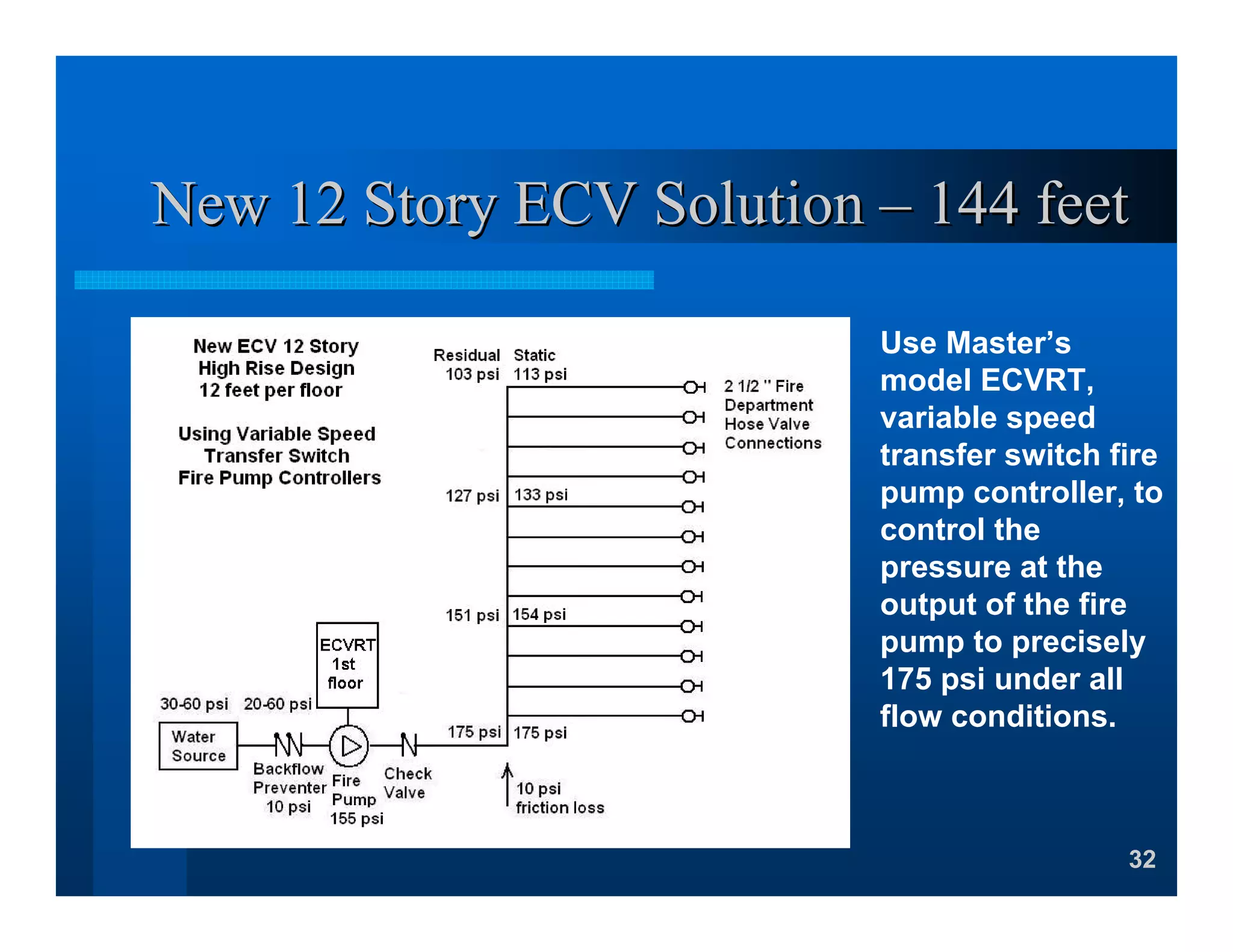

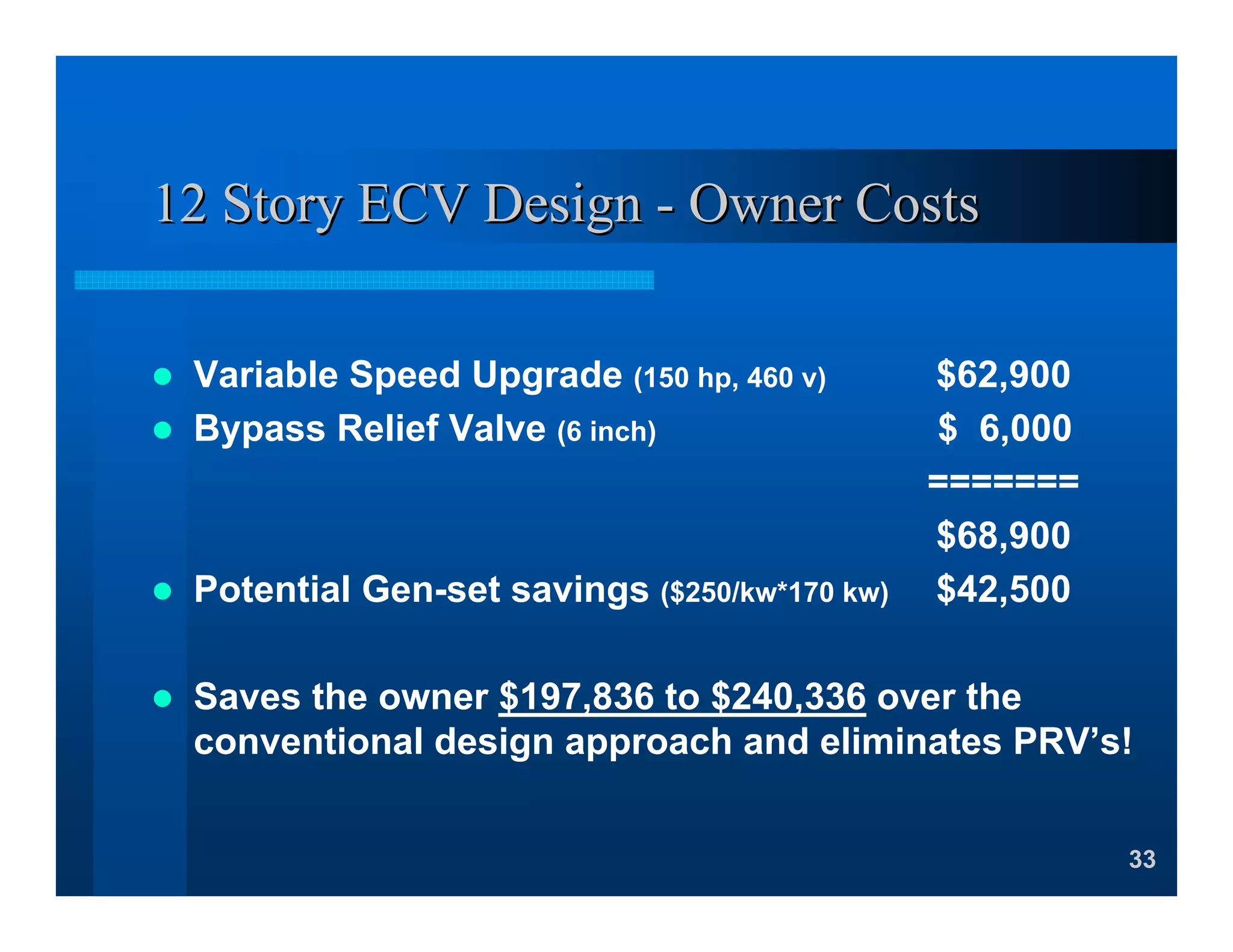

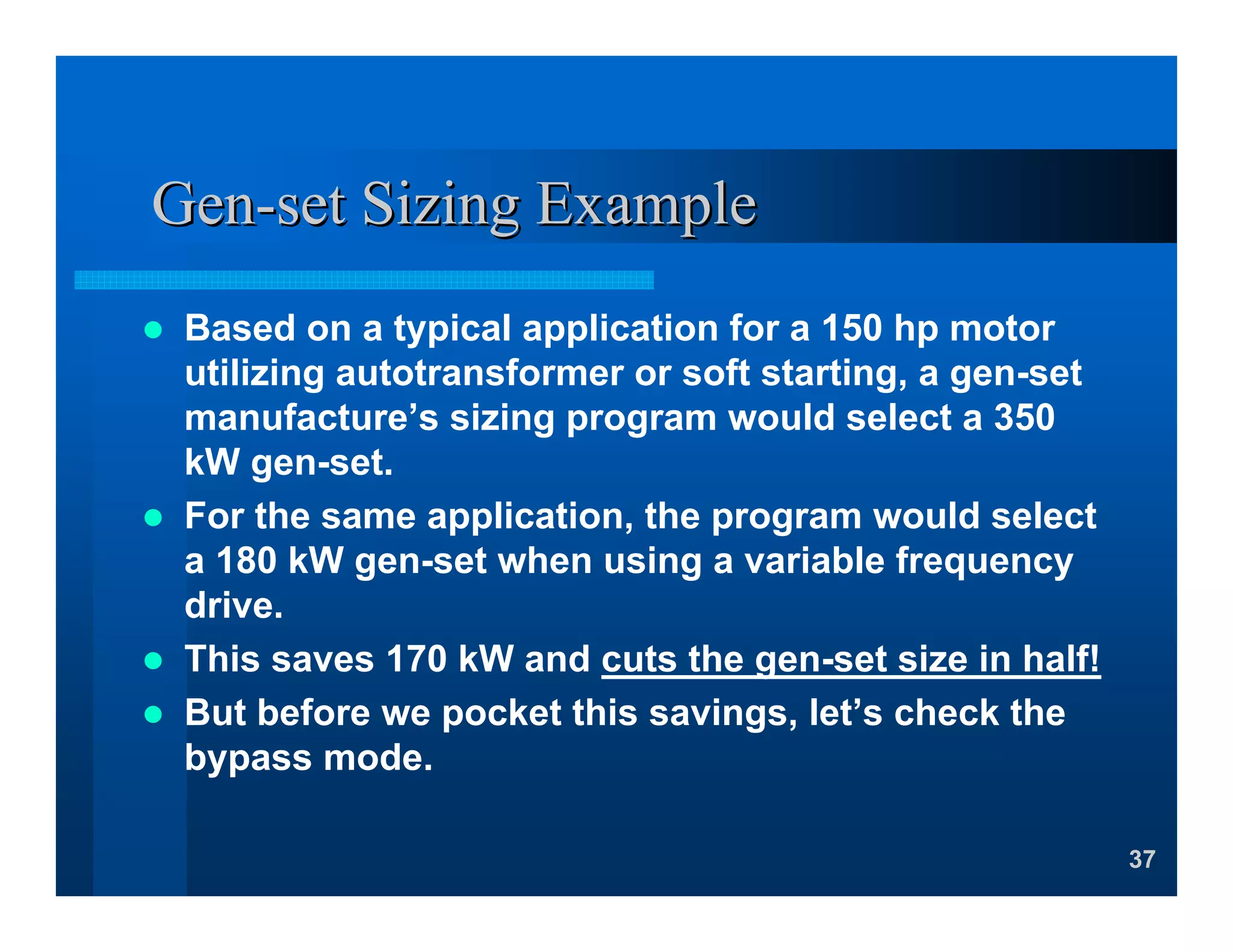

This document discusses the benefits of variable speed fire pump controllers compared to conventional controllers. Variable speed controllers can maintain a constant system pressure without the need for pressure reducing valves (PRVs) by adjusting the pump speed. This allows taller buildings to be designed without PRVs, saving significant costs. It also improves reliability by having redundant control circuits. While conventional controllers require PRVs for most floors in a 12-story building example, incurring high costs, a variable speed controller can maintain safe pressures on all floors without PRVs.