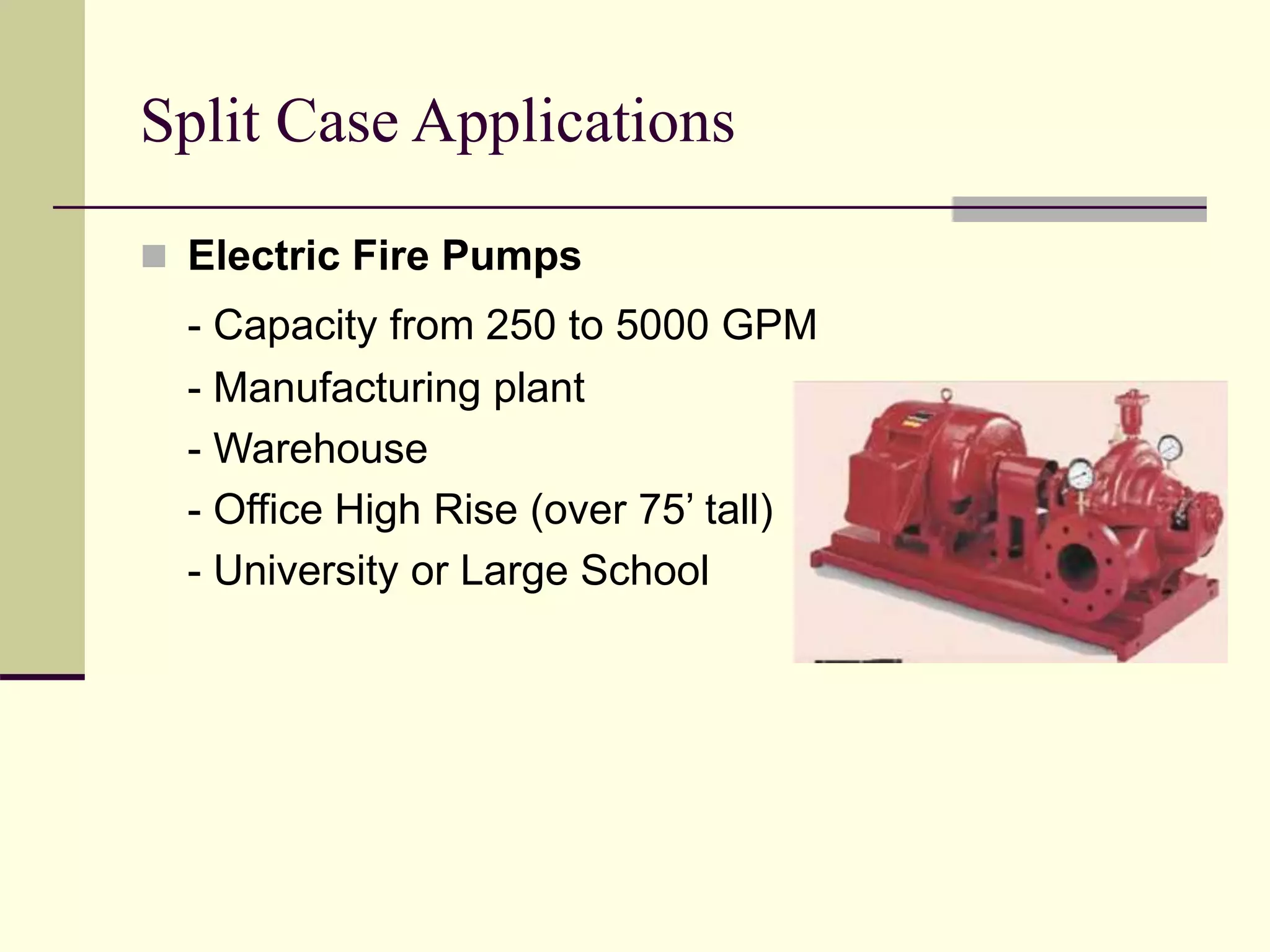

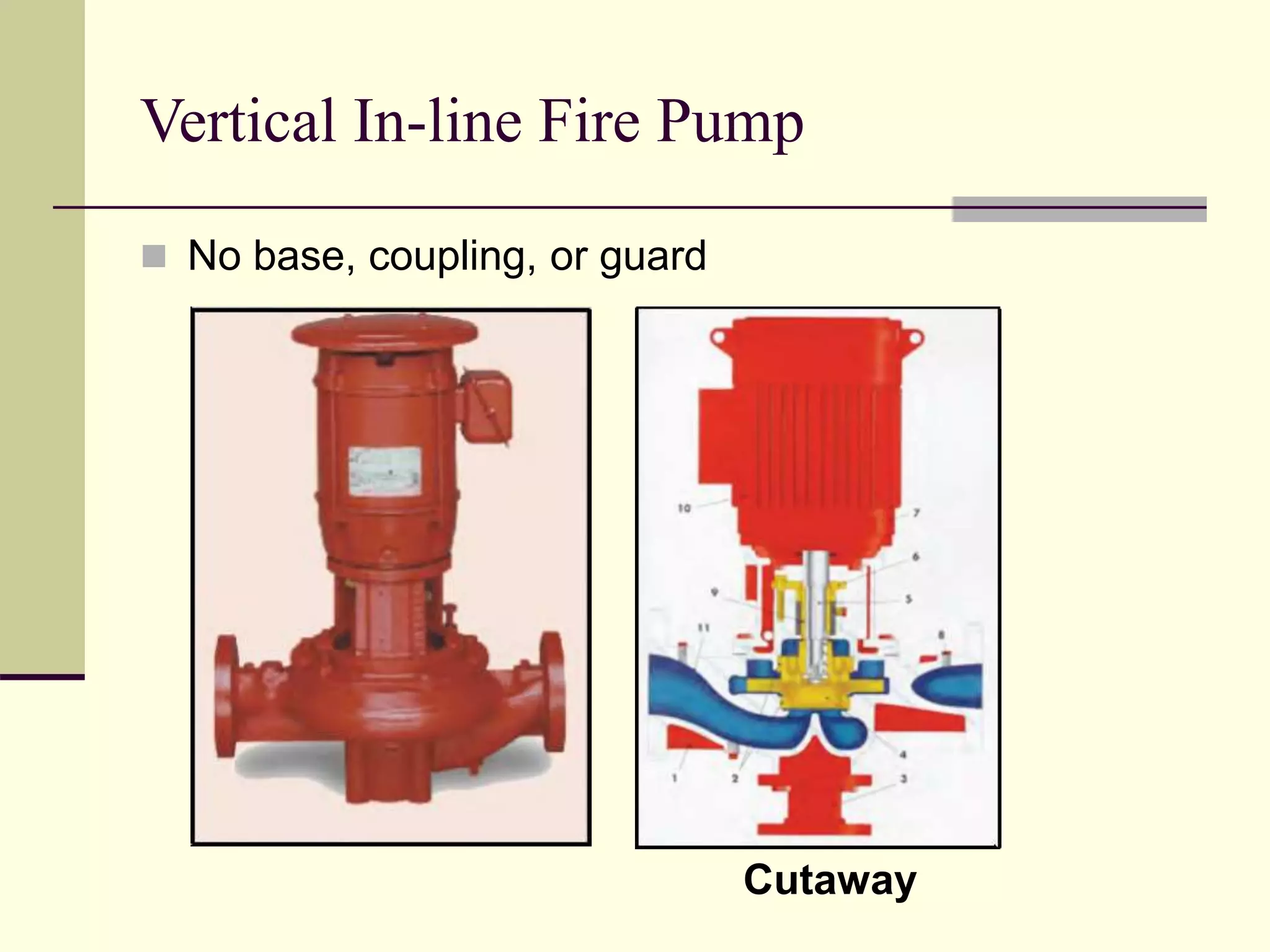

The document discusses fire water pump systems, including their purpose of protecting life and property. It provides an overview of key components such as the pump, driver, controller, and sensing line arrangement. The document outlines pump characteristics, rated capacities, materials used, water supply sources, and types of pumps. It also discusses pump installation, jockey pumps, diesel, electric, and steam fire pump systems and their components. Testing organizations such as UL and FM are described.