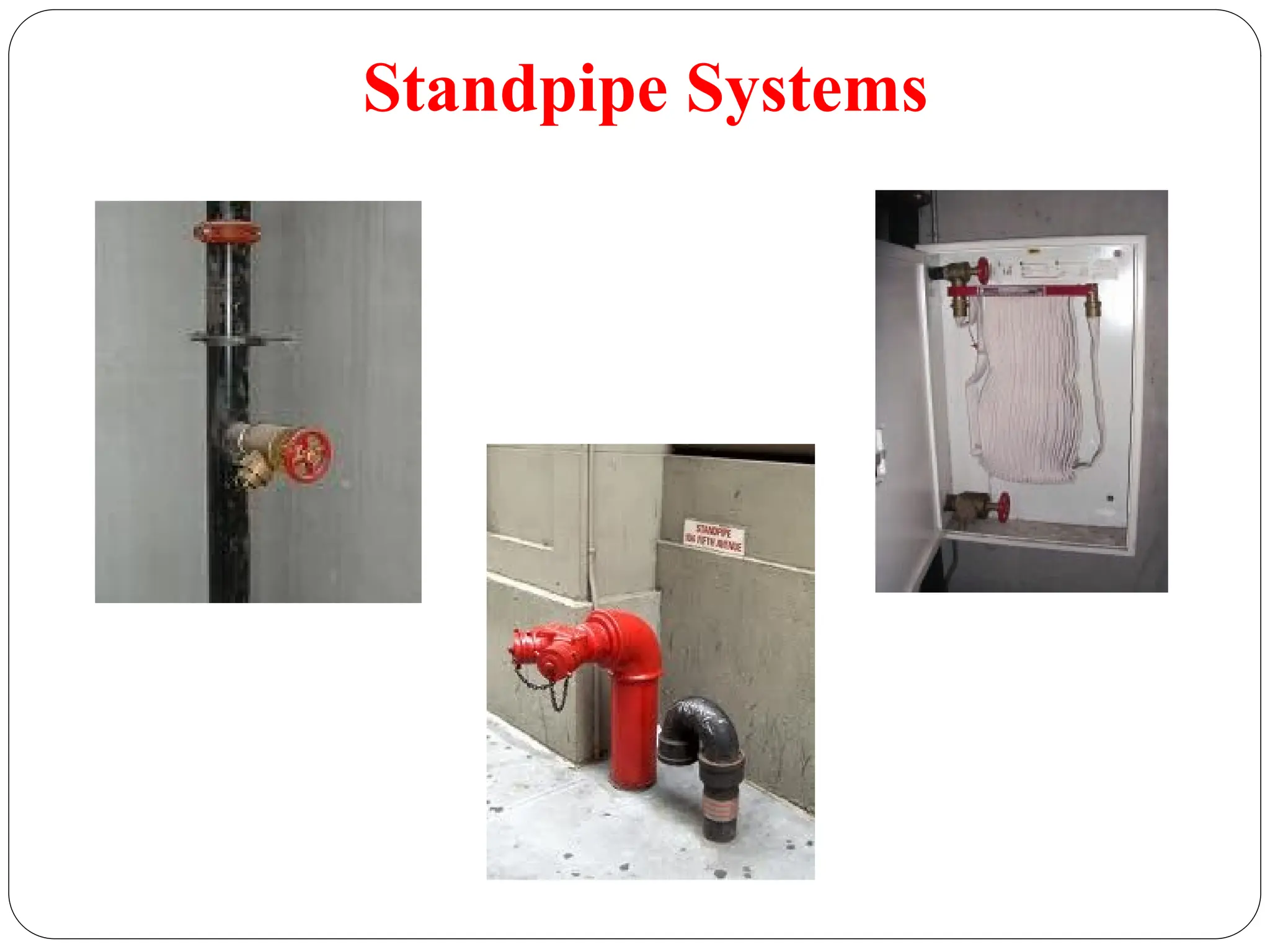

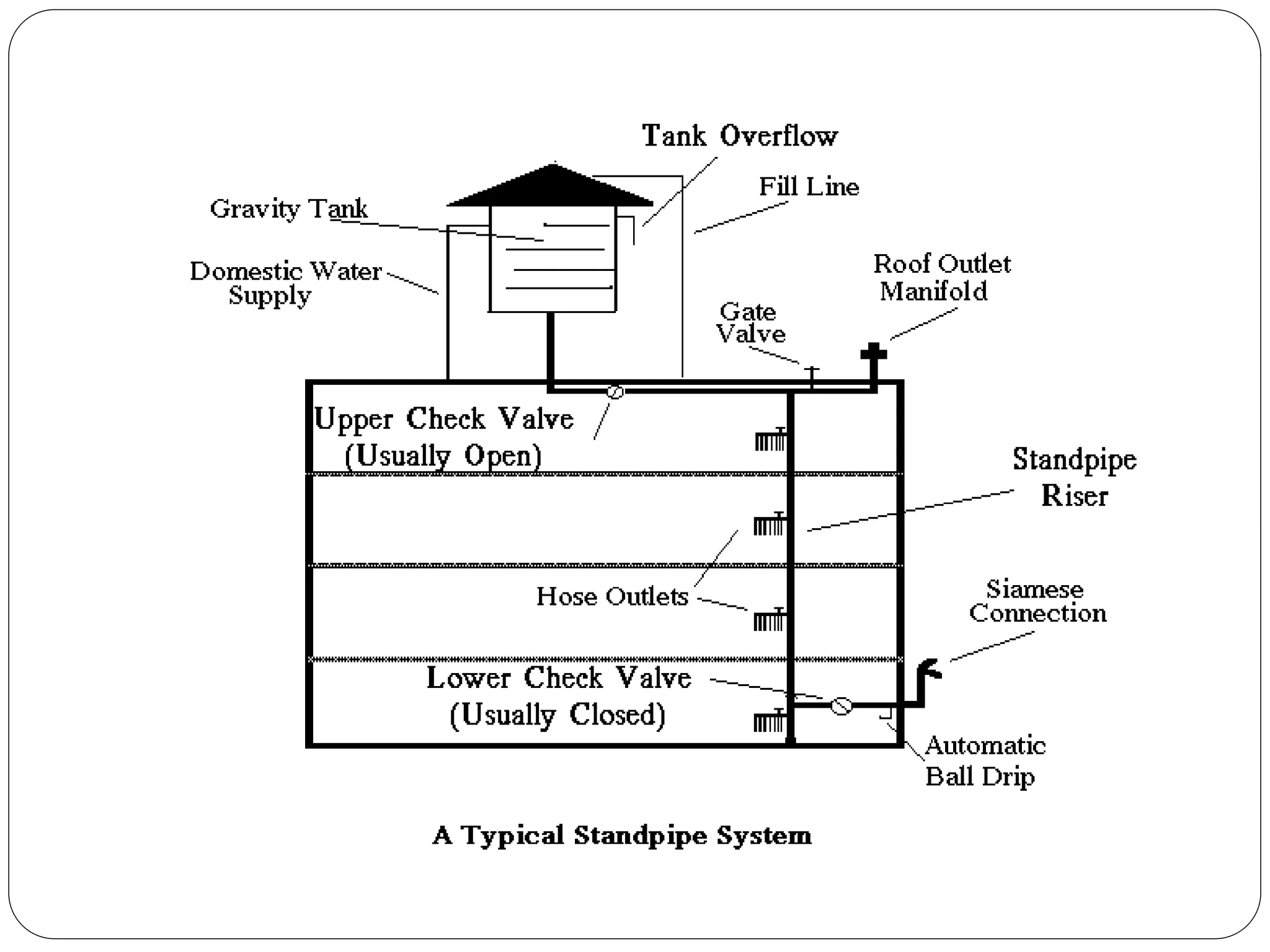

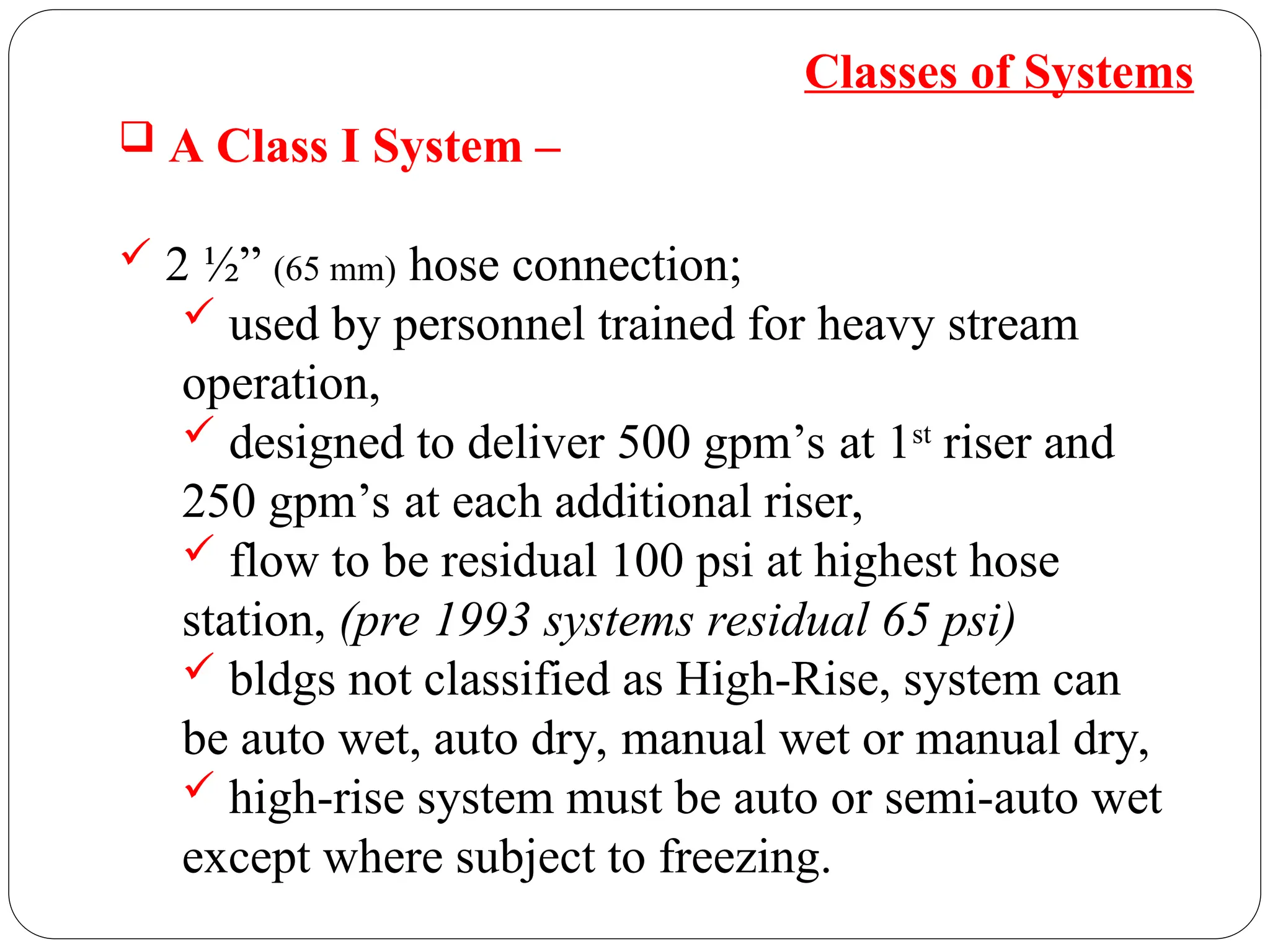

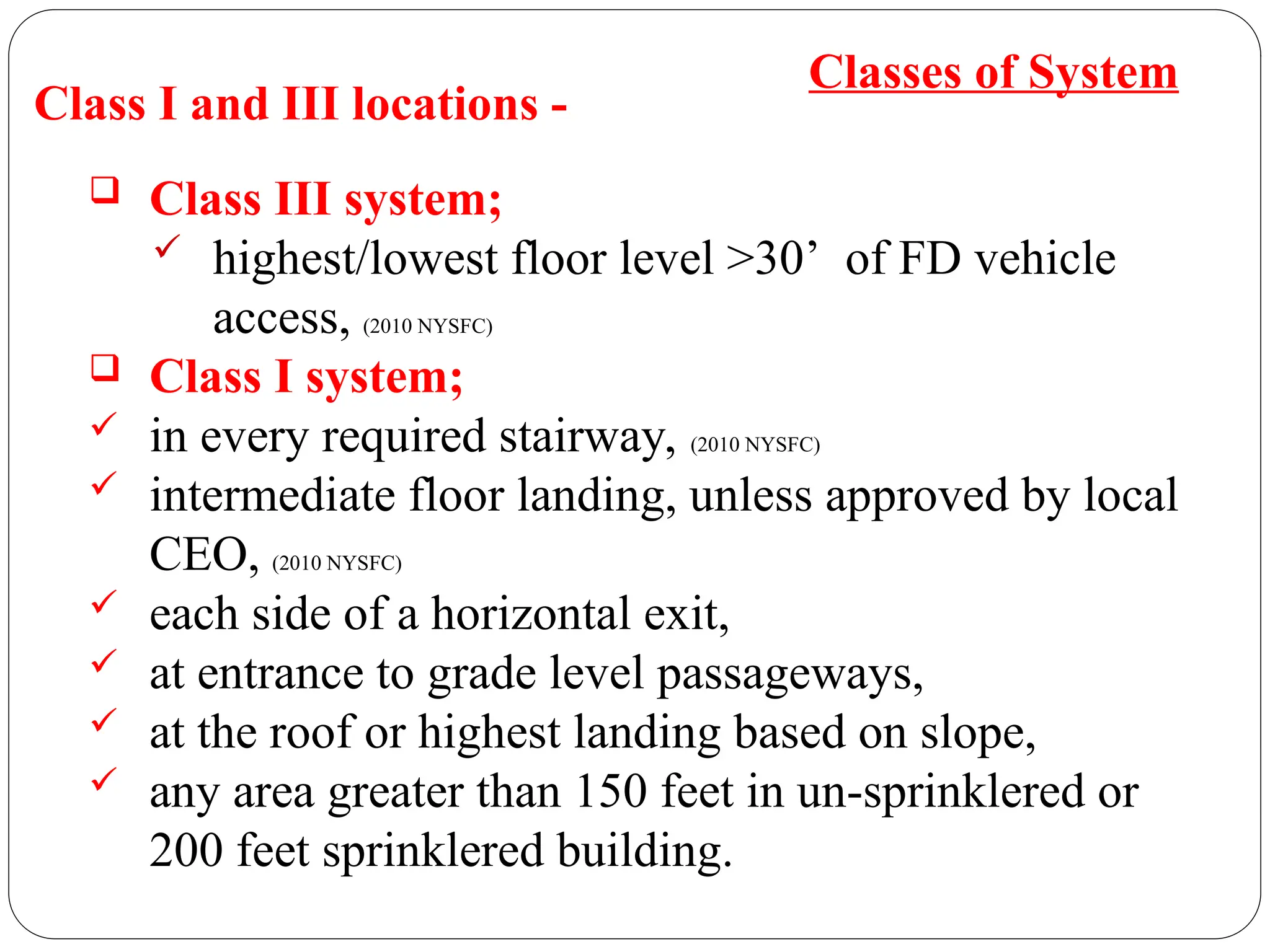

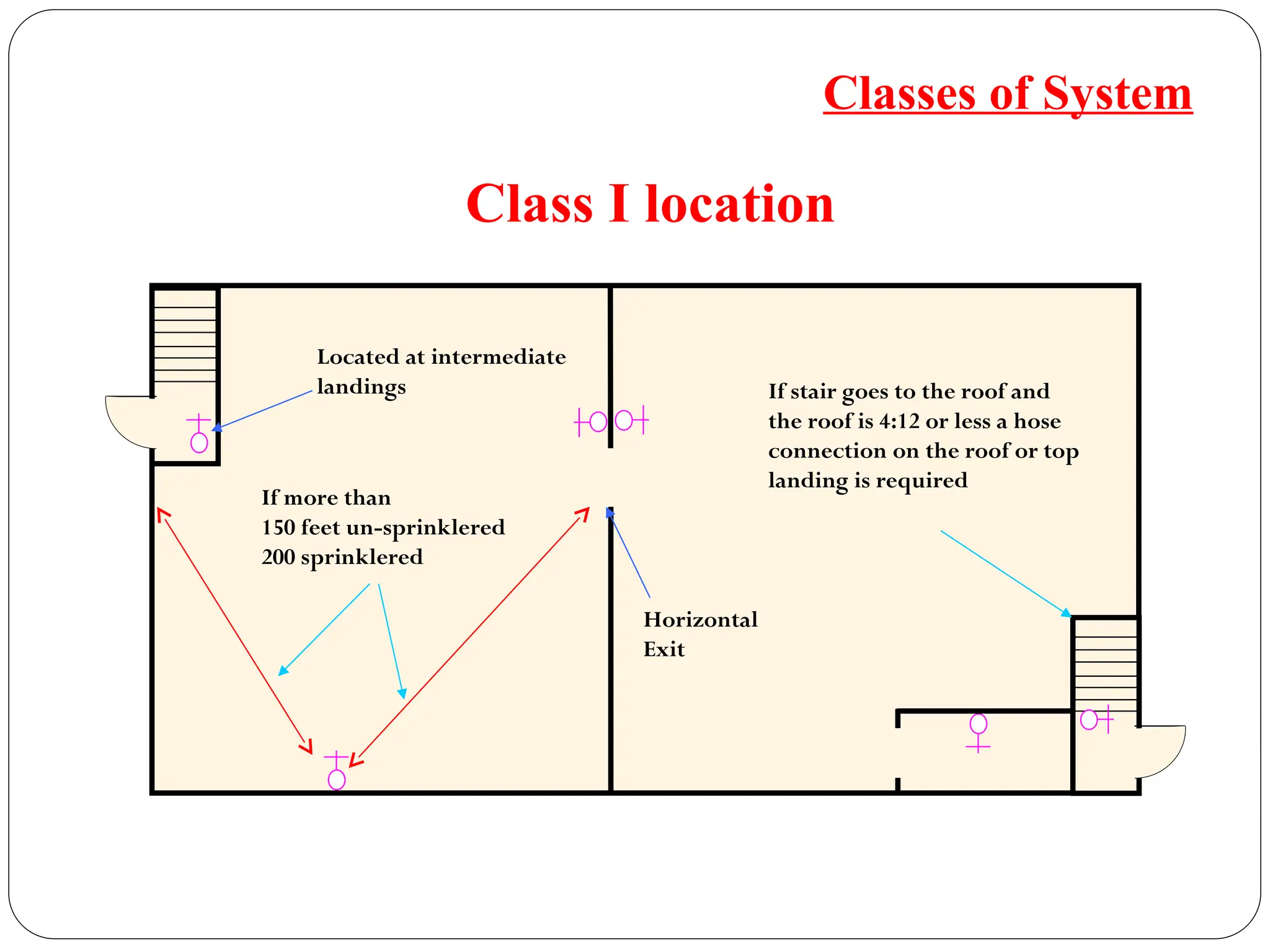

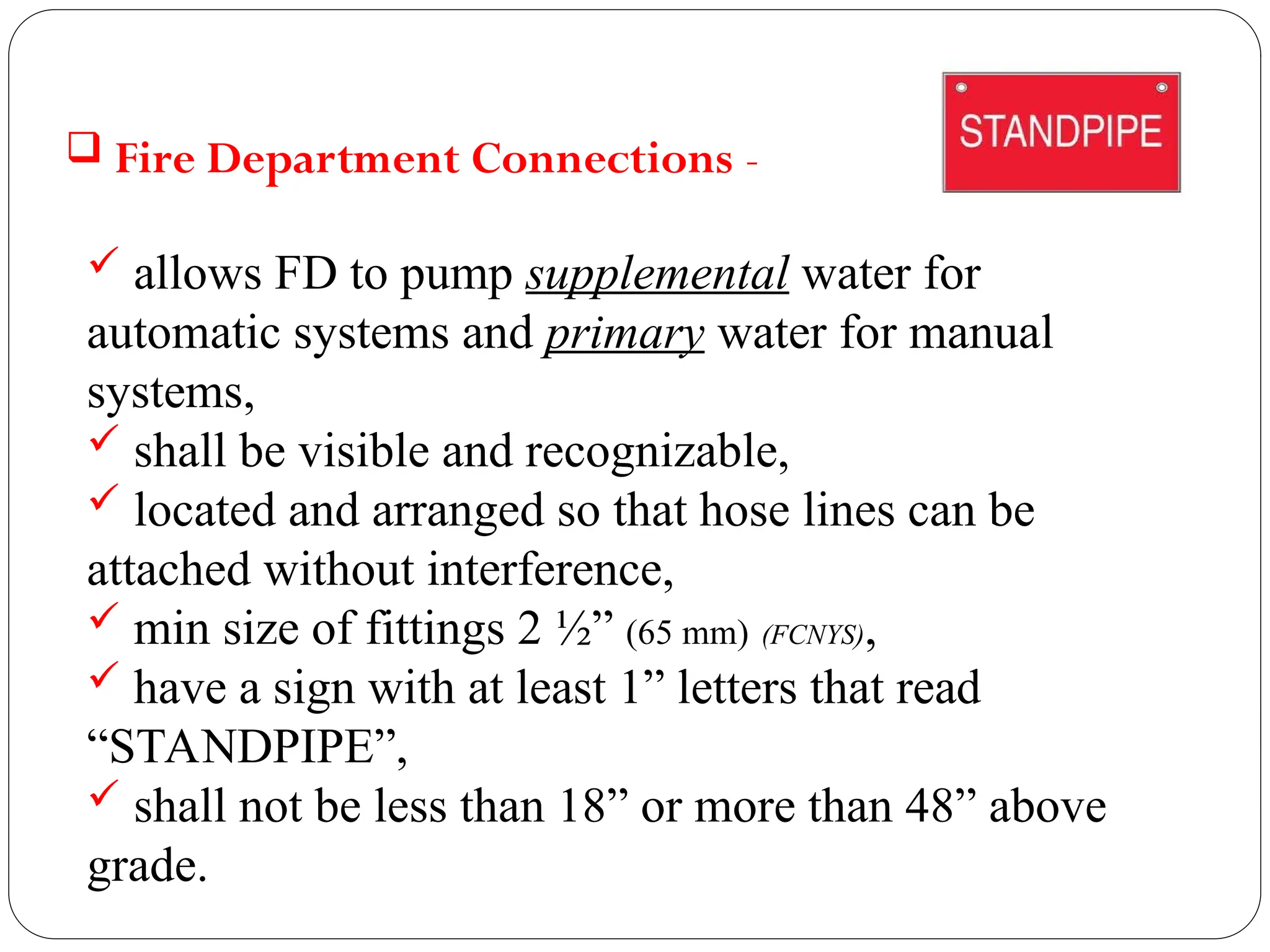

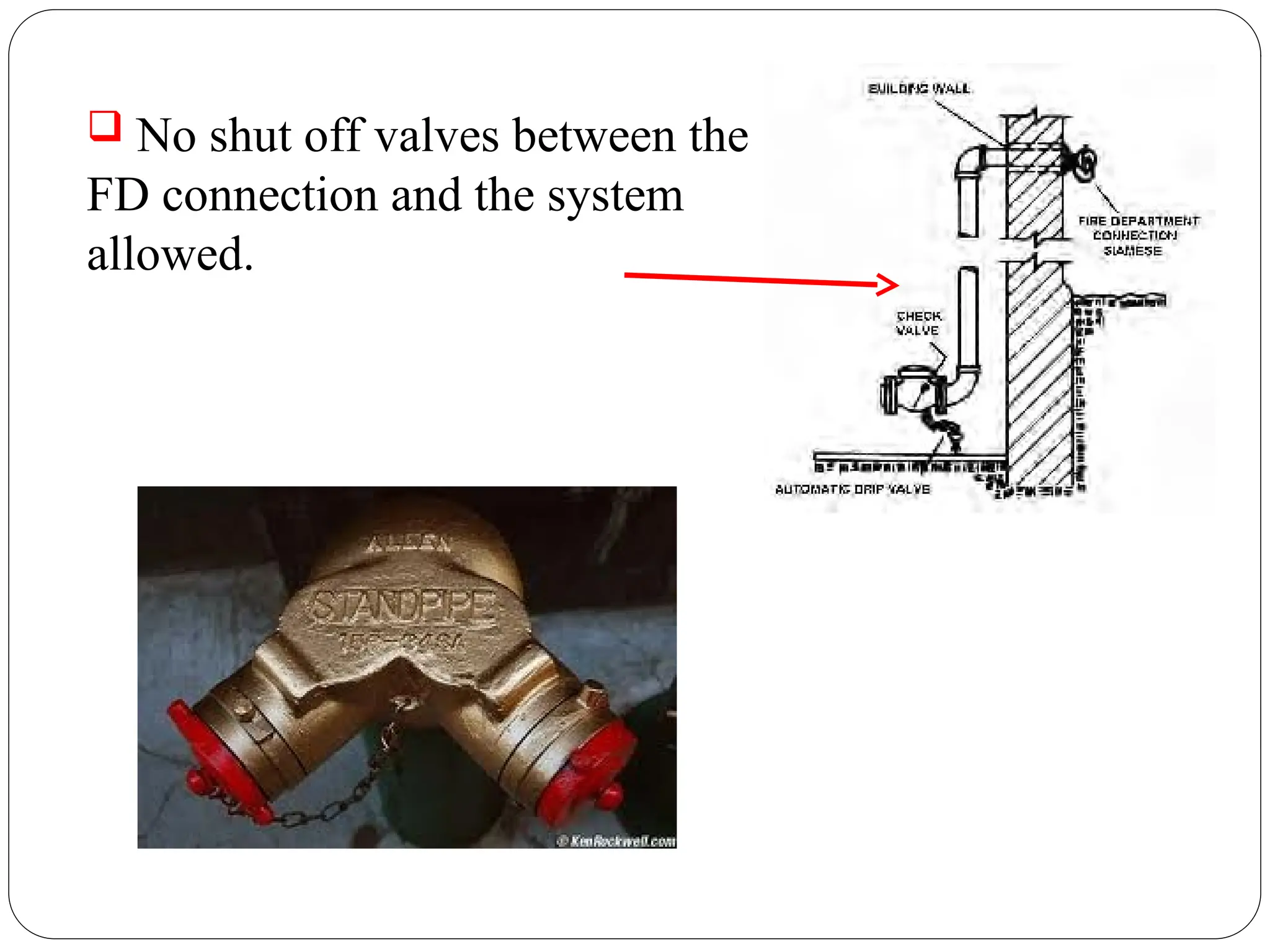

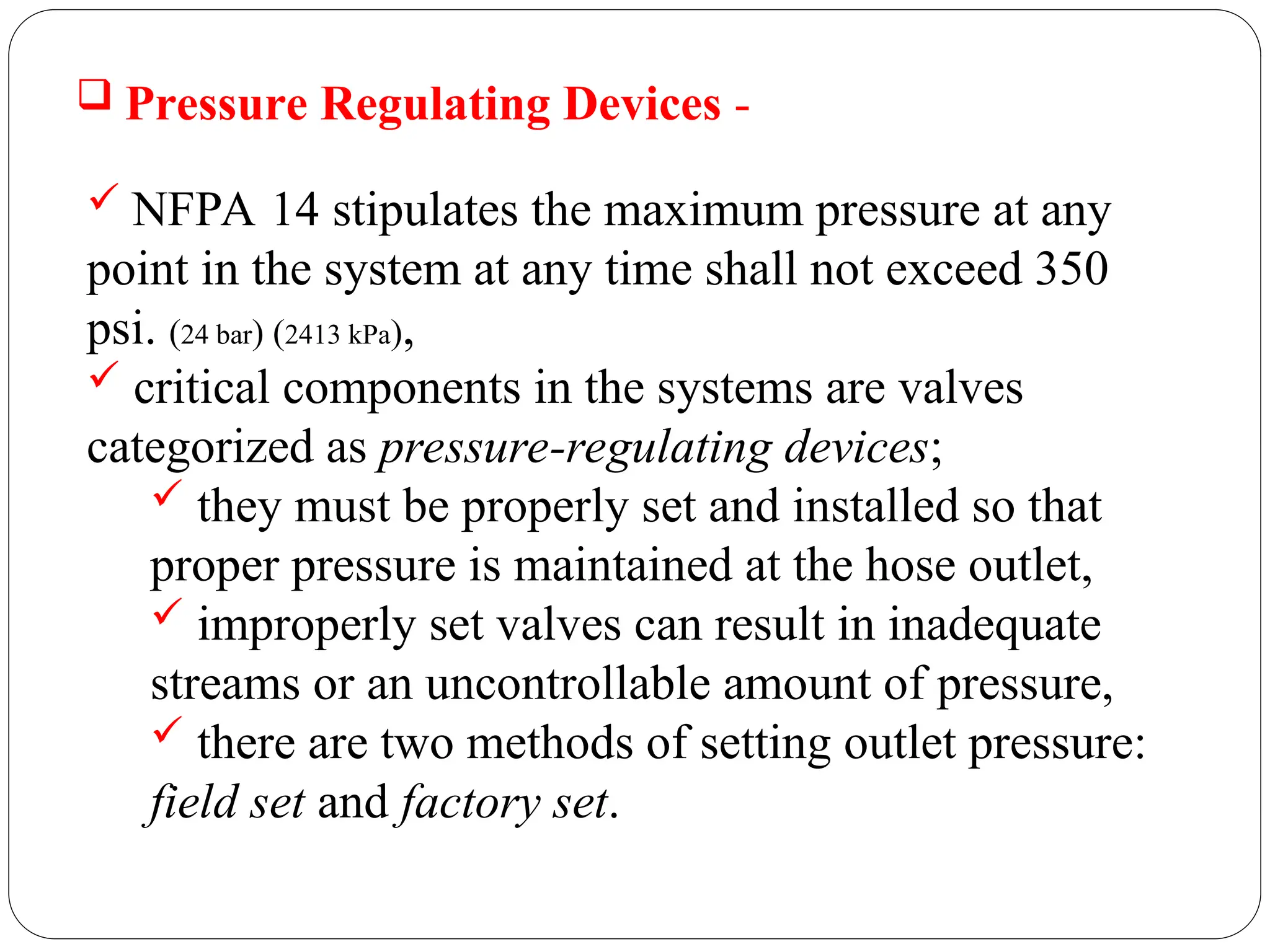

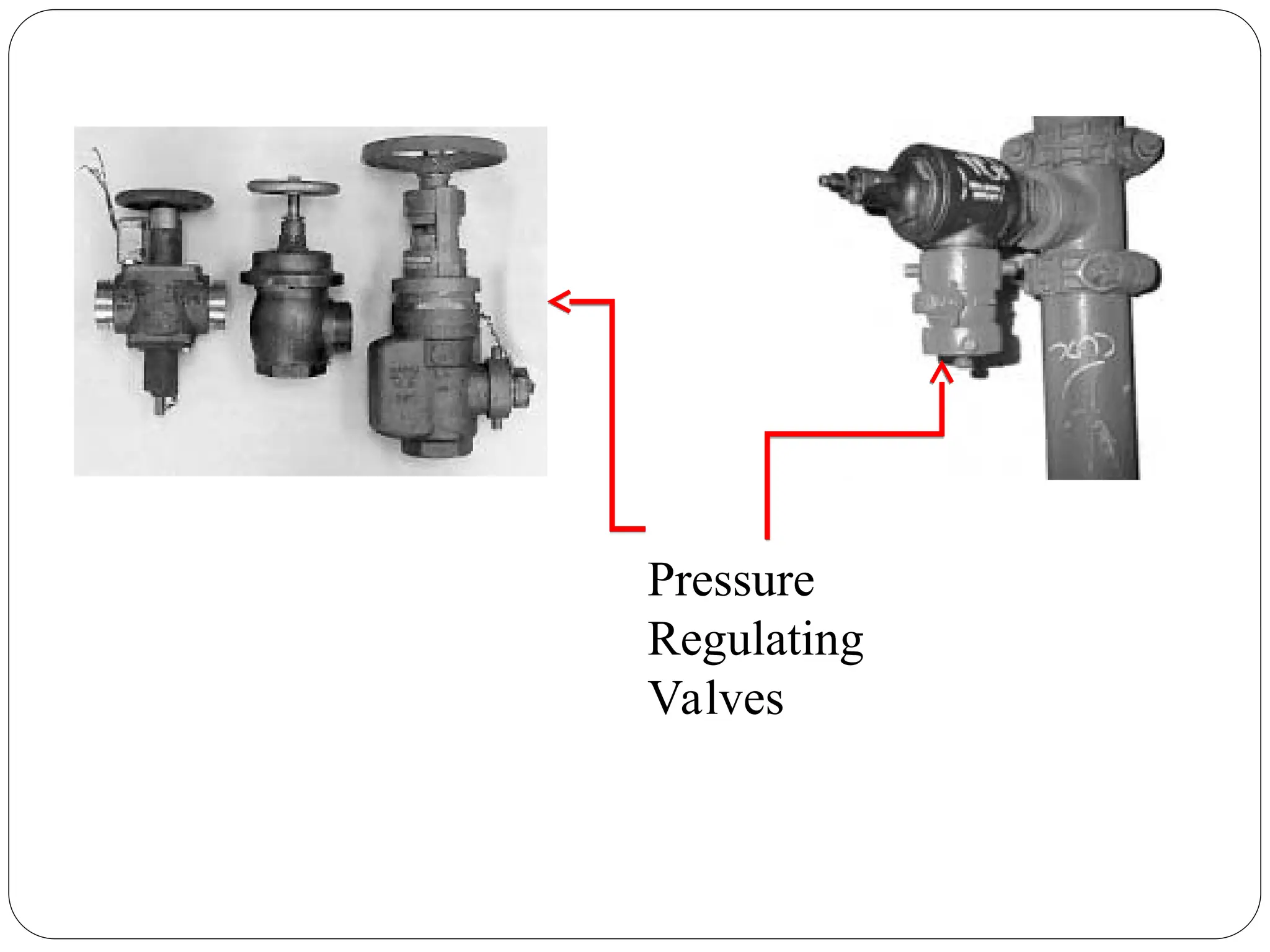

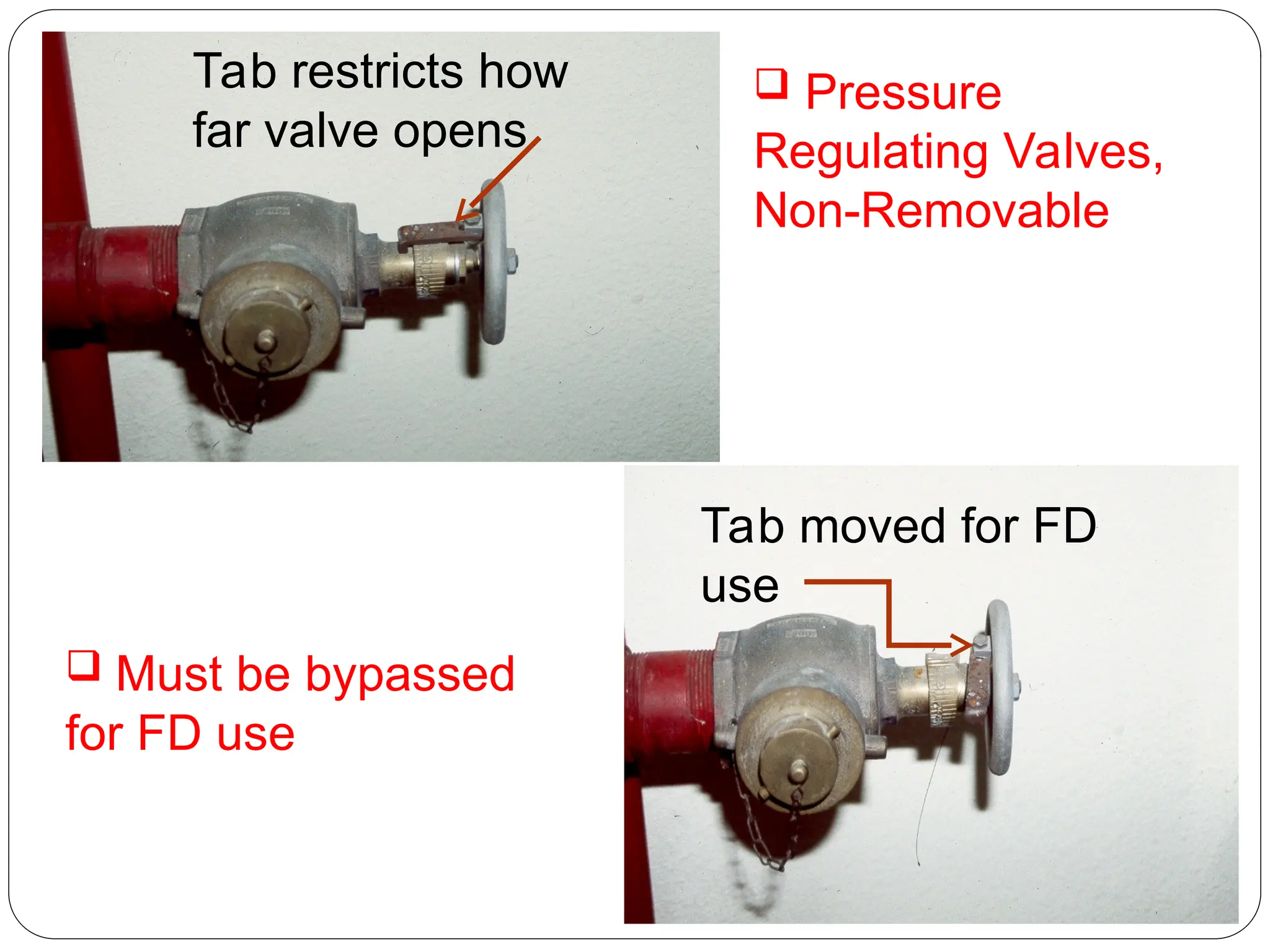

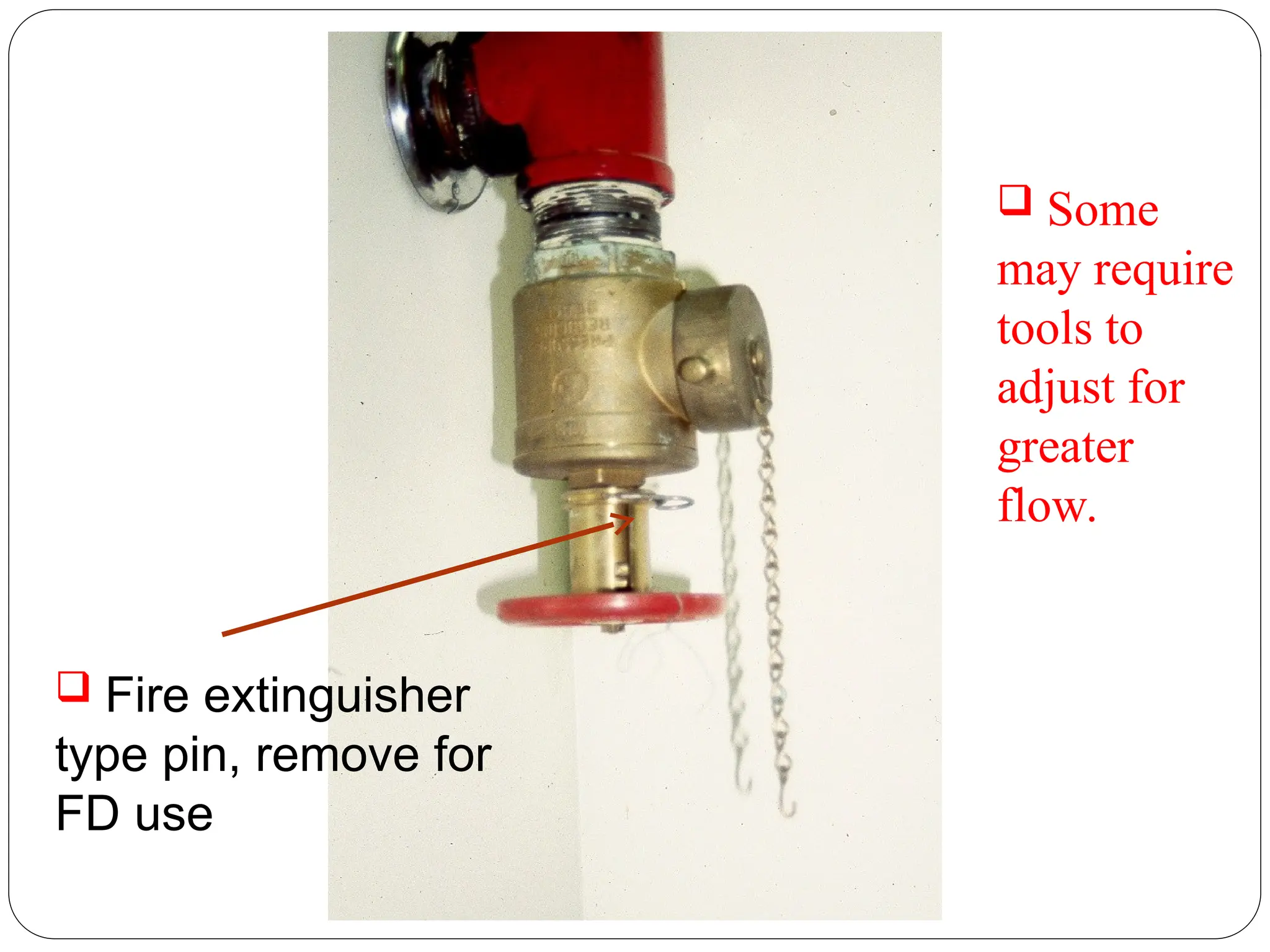

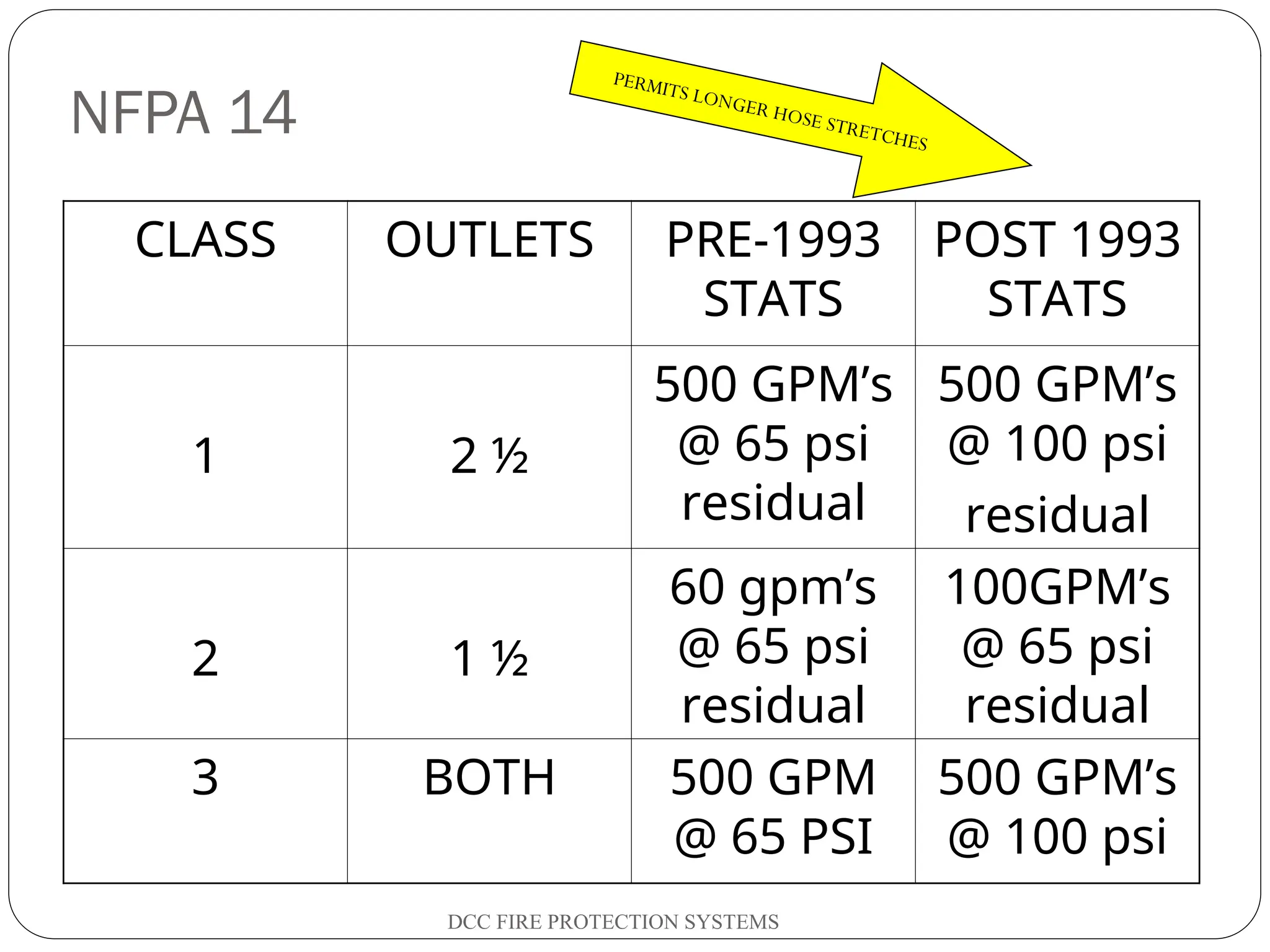

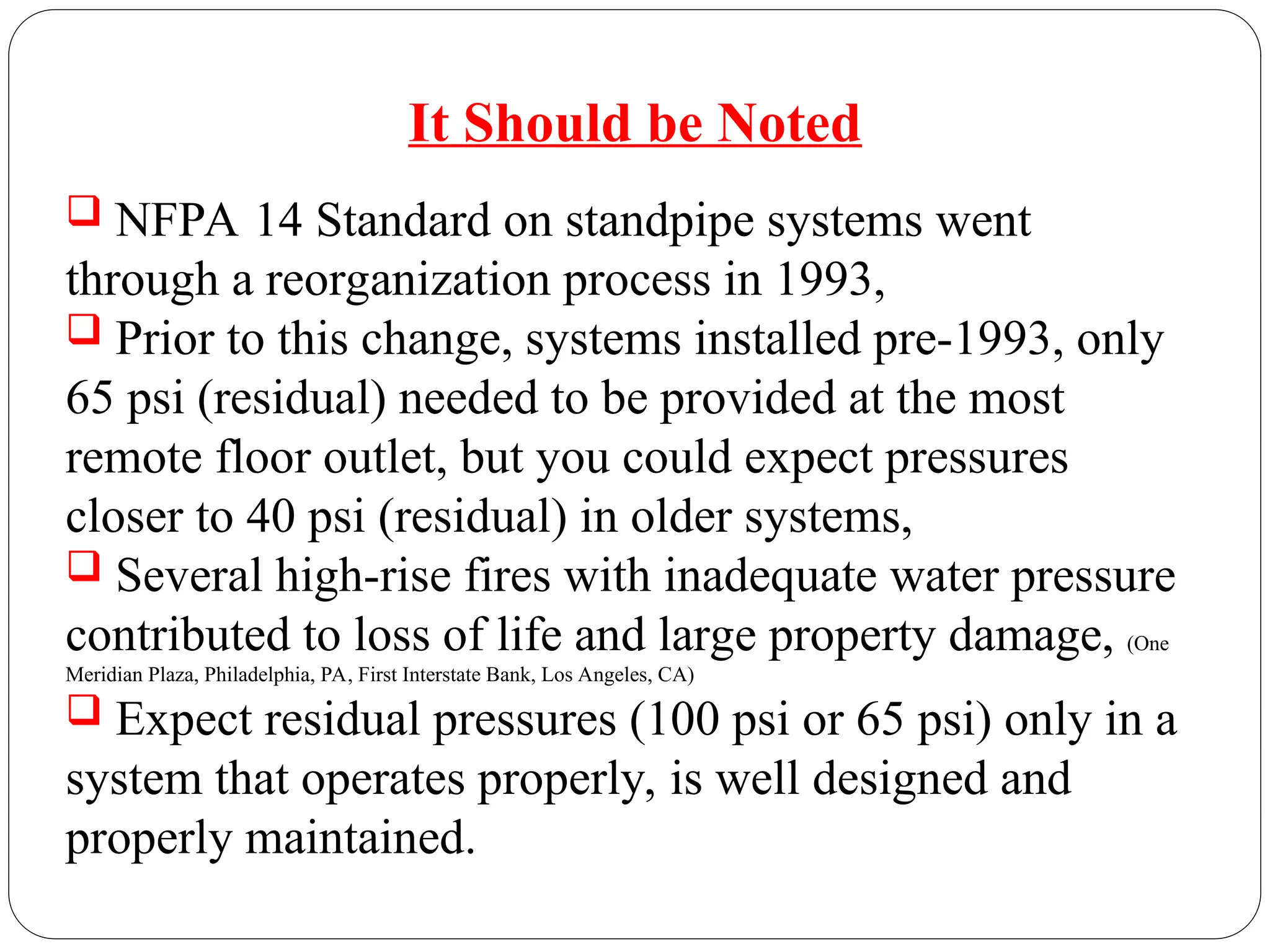

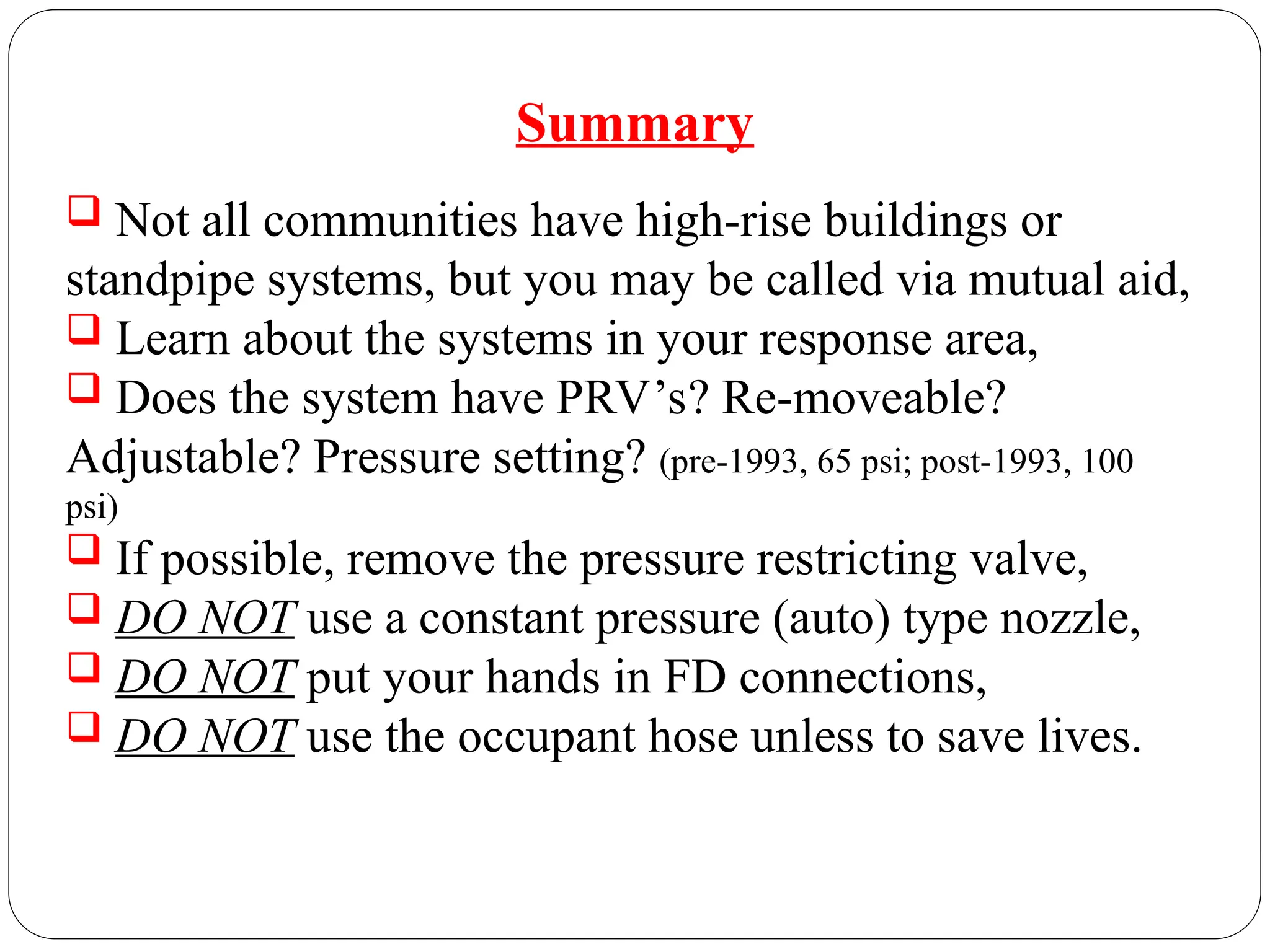

A standpipe system is a fire safety mechanism that provides firefighters with immediate access to water during a fire event through fixed piping systems, functioning similarly to fire hydrants. Over its century-long history, these systems have evolved to serve high-rise buildings, public spaces, and various facilities, with specific installation and inspection standards outlined in NFPA codes. There are various types and classes of standpipe systems, classified by their operation (wet or dry) and hose connections, tailored to effectively deliver water to combat fires in different building structures.