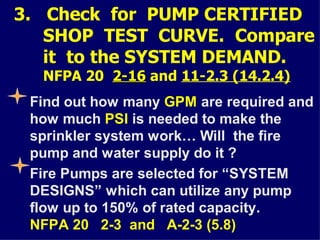

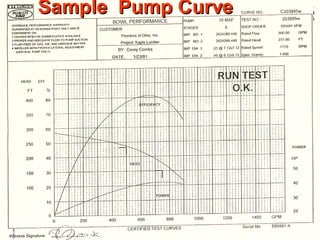

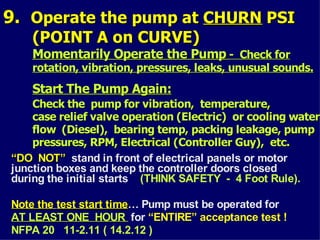

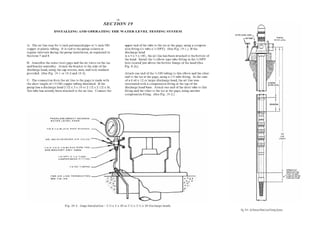

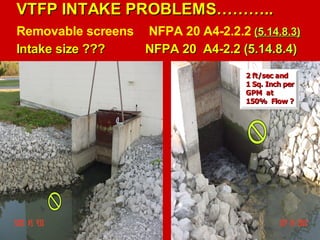

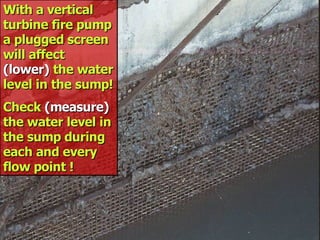

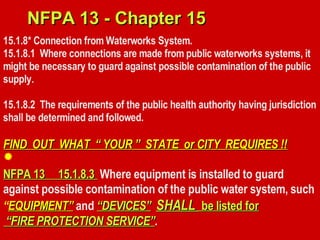

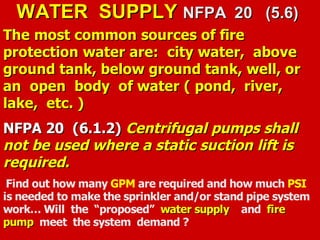

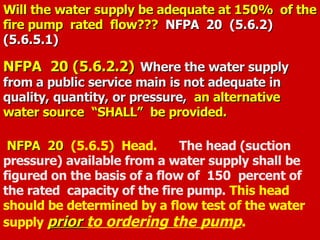

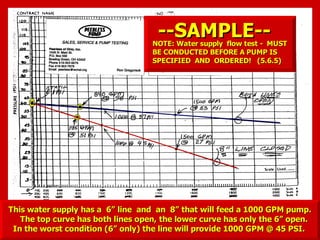

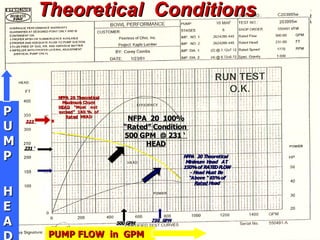

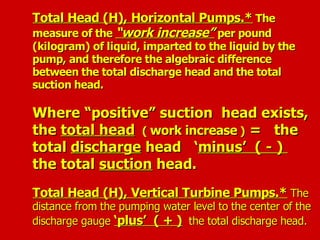

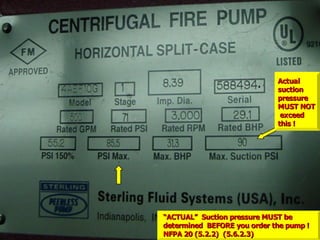

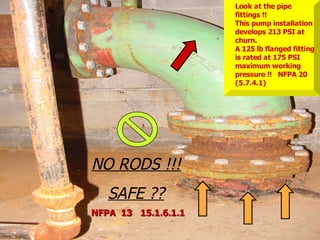

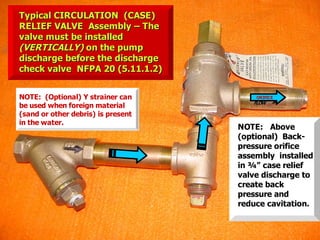

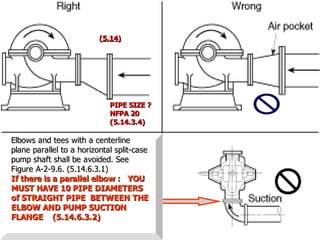

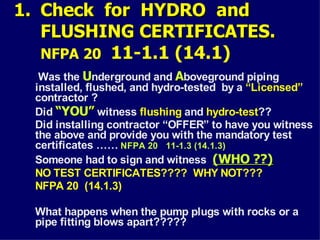

The document outlines definitions and regulations from NFPA 20 regarding fire protection systems, focusing on the authority having jurisdiction, accepted standards for equipment and installations, and water supply requirements for fire pumps. It specifies the need for adequate water supply and pressure to maintain fire protection systems and details the acceptable configurations of pump installations and their components. Additionally, it emphasizes the importance of conducting water supply flow tests before pump specification to ensure proper operational capabilities.

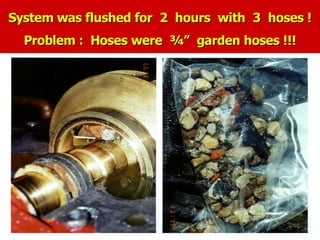

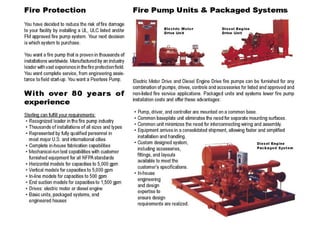

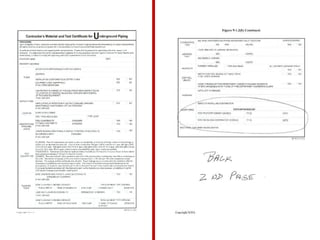

![Table (14.1.1.1[a])

Table (14.1.1.1[a]) Minimum Flush Rates

Minimum Flush Rates.

.

Contractor may have a calculated system

Contractor may have a calculated system

demand which, if greater, will require higher

demand which, if greater, will require higher

flush rates than those listed below.

flush rates than those listed below.

Pipe Size

Pipe Size Flow Rate

Flow Rate

in.

in. mm

mm gpm

gpm L/min

L/min

4

4 102

102 590

590 2,233

2,233

6

6 152

152 1,360

1,360 5,148

5,148

8

8 203

203 2,350

2,350 8,895

8,895

10

10 254

254 3,670

3,670 13,891

13,891

12

12 305

305 5,290

5,290 20,023

20,023

NFPA 20 (14.1.1.1) FLUSHING

NFPA 20 (14.1.1.1) FLUSHING](https://image.slidesharecdn.com/firepumptutorial-240530183554-6744ac79/85/Fire-Pump-Tutorial-as-per-NFPA-20-standard-117-320.jpg)