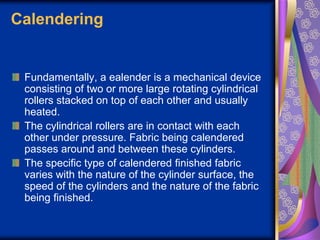

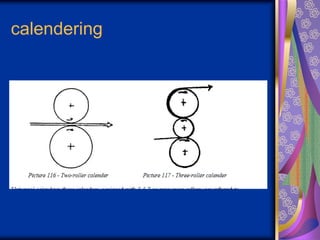

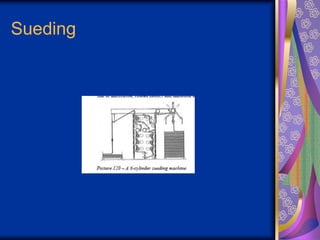

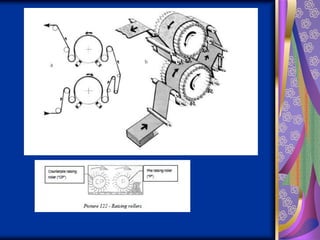

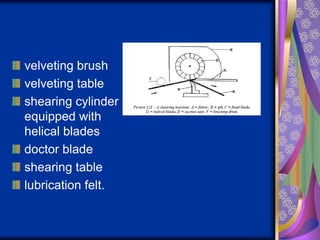

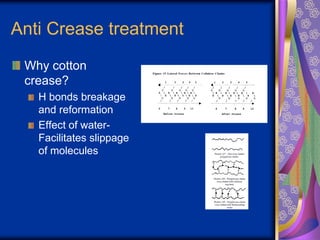

The document discusses textile finishing processes. It begins by introducing textiles and their basic components and materials. It then describes the major departments of textiles - spinning, weaving, and wet-processing. Wet-processing involves pretreatments like scouring and bleaching, dyeing and printing, and finishing treatments like calendaring to impart properties like softness and durability. Specific mechanical finishing processes are also outlined, including sueding, raising, shearing, and decating. Calendaring is discussed in detail as a process that smoothes fabrics and modifies properties.