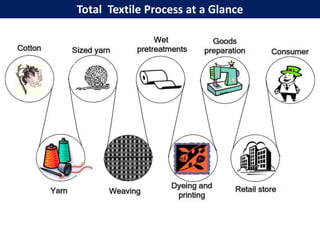

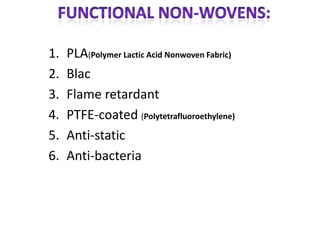

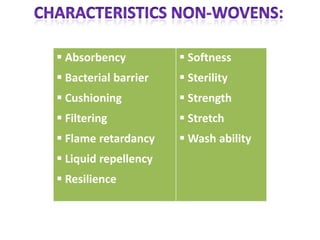

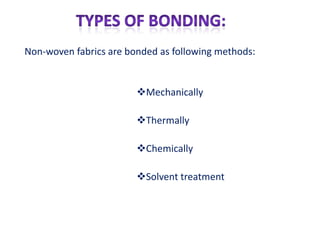

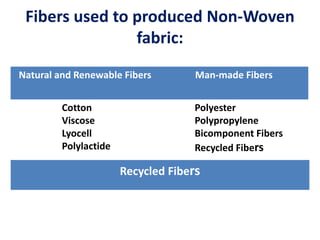

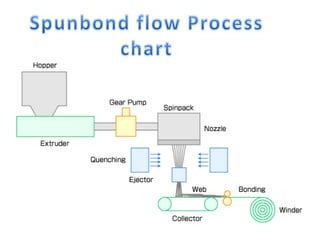

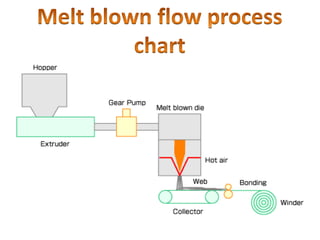

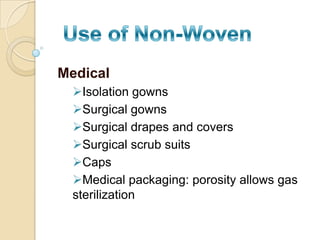

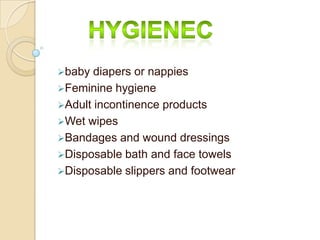

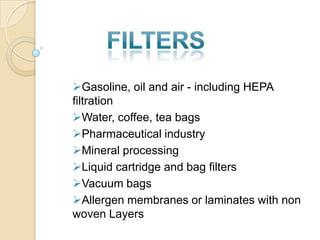

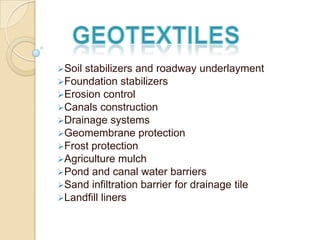

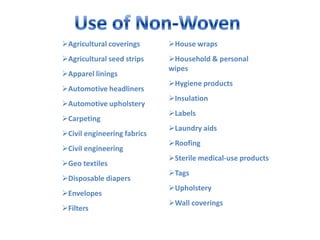

This document provides an overview of non-woven fabrics. It defines non-woven fabrics as sheet or web structures bonded together by entangling fibers or filaments mechanically, thermally, chemically or through solvent treatment. The document discusses the history of non-woven fabrics and mentions some early precursors. It also outlines different types of non-woven fabrics based on materials used and manufacturing processes. Common applications of non-woven fabrics in various industries are also summarized.