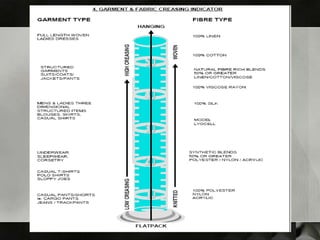

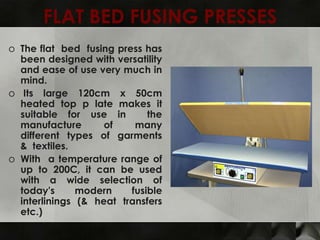

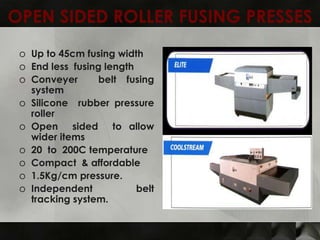

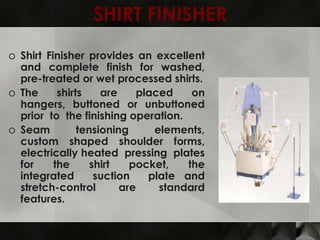

The document discusses various garment finishing processes and equipment. It describes spotting processes that use hazardous chemicals and safer alternatives. It also covers folding, packing, hanging, pressing and finishing of different garments using specialized machines like shirt folders, steam irons, and finishers tailored for different garment types. Safety features of folding equipment like jam prevention systems are highlighted.