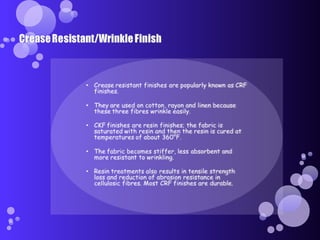

The document discusses various types of fabric finishes including:

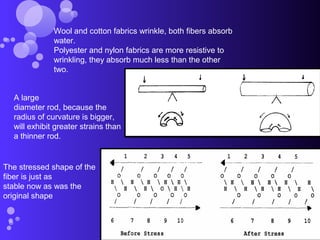

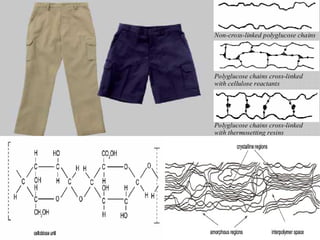

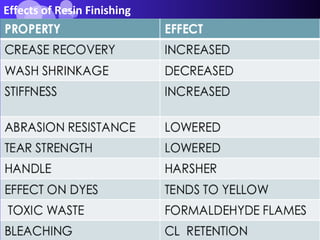

- Resin finishes which increase the intermolecular rigidity of cellulosic fabrics like cotton to reduce creasing.

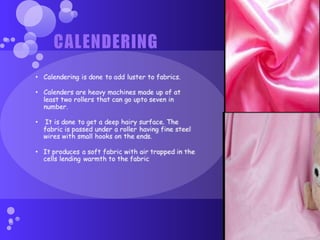

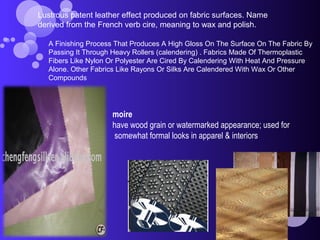

- Glazed finishes which produce a highly polished surface using calendaring.

- Moire finishes which create a wood grain or watermarked appearance.

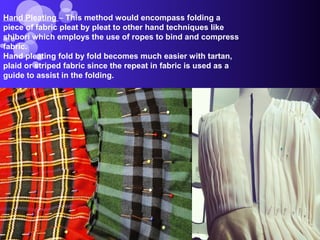

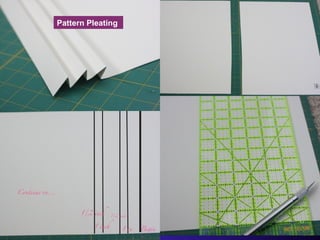

- Pleated finishes which can be produced by hand folding or using patterned papers and machine blades.

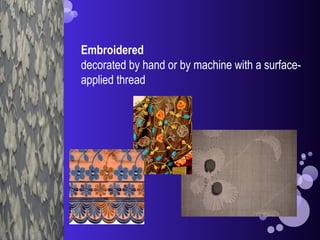

- Embroidered finishes which involve decorating fabrics with surface-applied thread by hand or machine.

- Parchmentized finishes which make cotton fabrics transparent, stiff and sheer through sulfuric acid treatment.