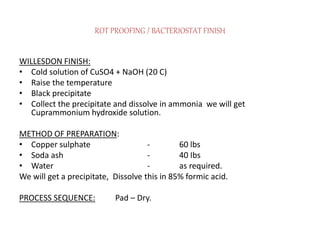

This document discusses anti-bacterial finishes that are applied to cellulosic fabrics like linen and cotton to make them resistant to bacteria. Rot proofing finishes protect fabrics from biological decay caused by mold, fungi and bacteria when exposed to moisture. Common active ingredients used in rot proofing finishes include compounds of antimony, bismuth, cadmium, cobalt and copper. Specific finishes mentioned include those using copper naphthanates and Willesden finish which uses a cuprammonium solution to treat canvas and tent cloth. The finish must not affect the fabric's properties or fastness and should be non-toxic, odorless and not discolor or degrade the fabric.