Embed presentation

Download to read offline

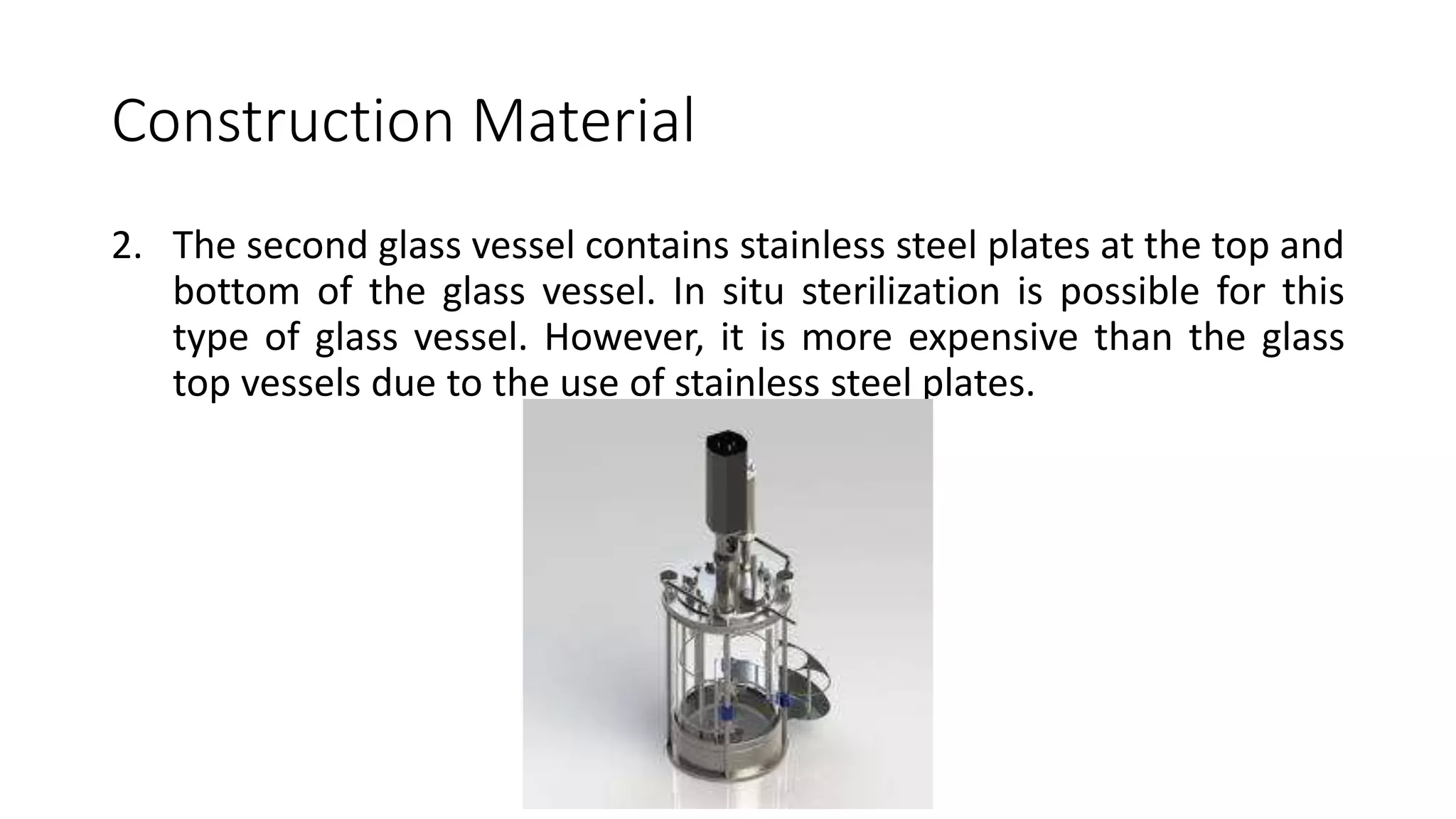

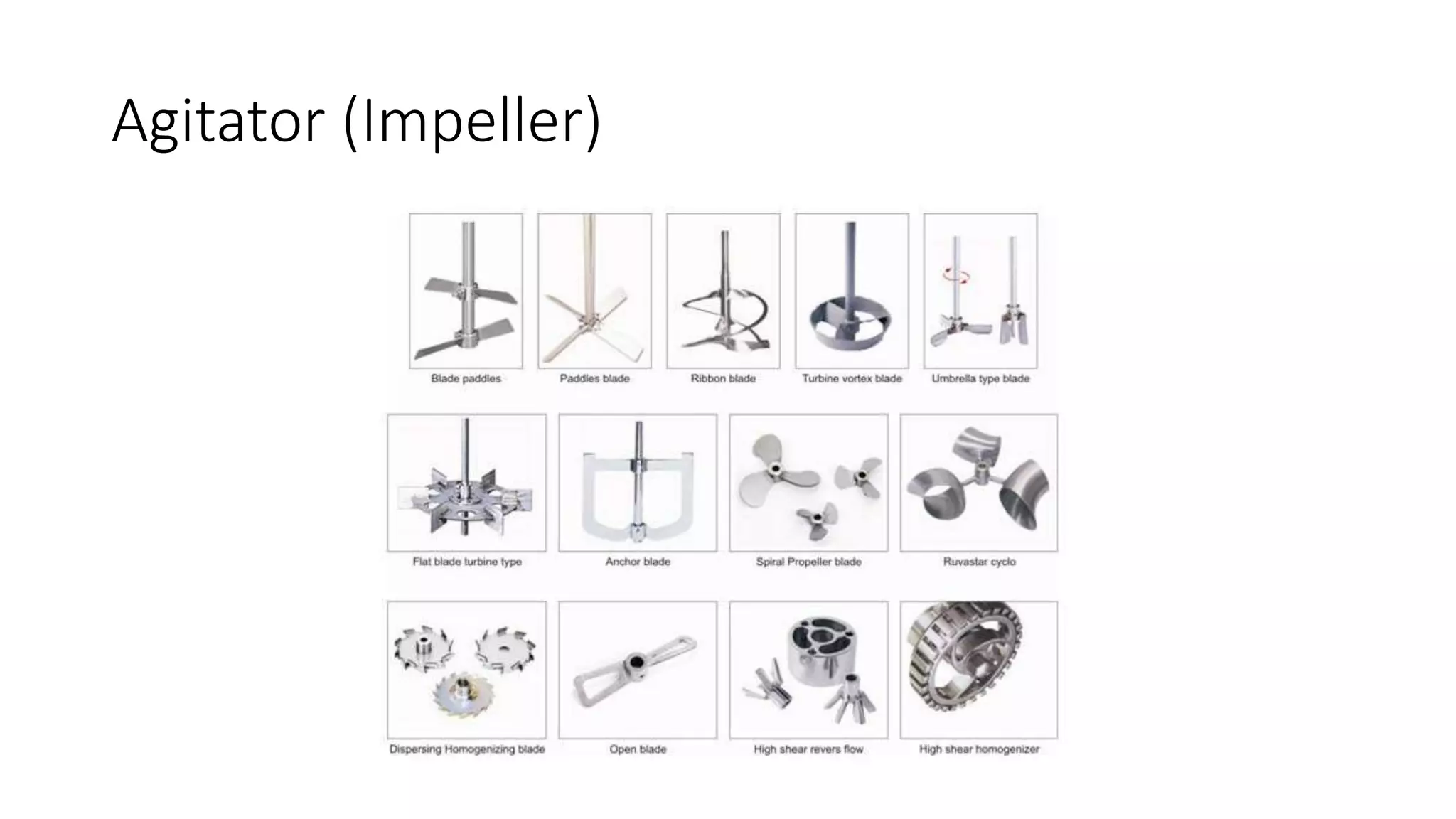

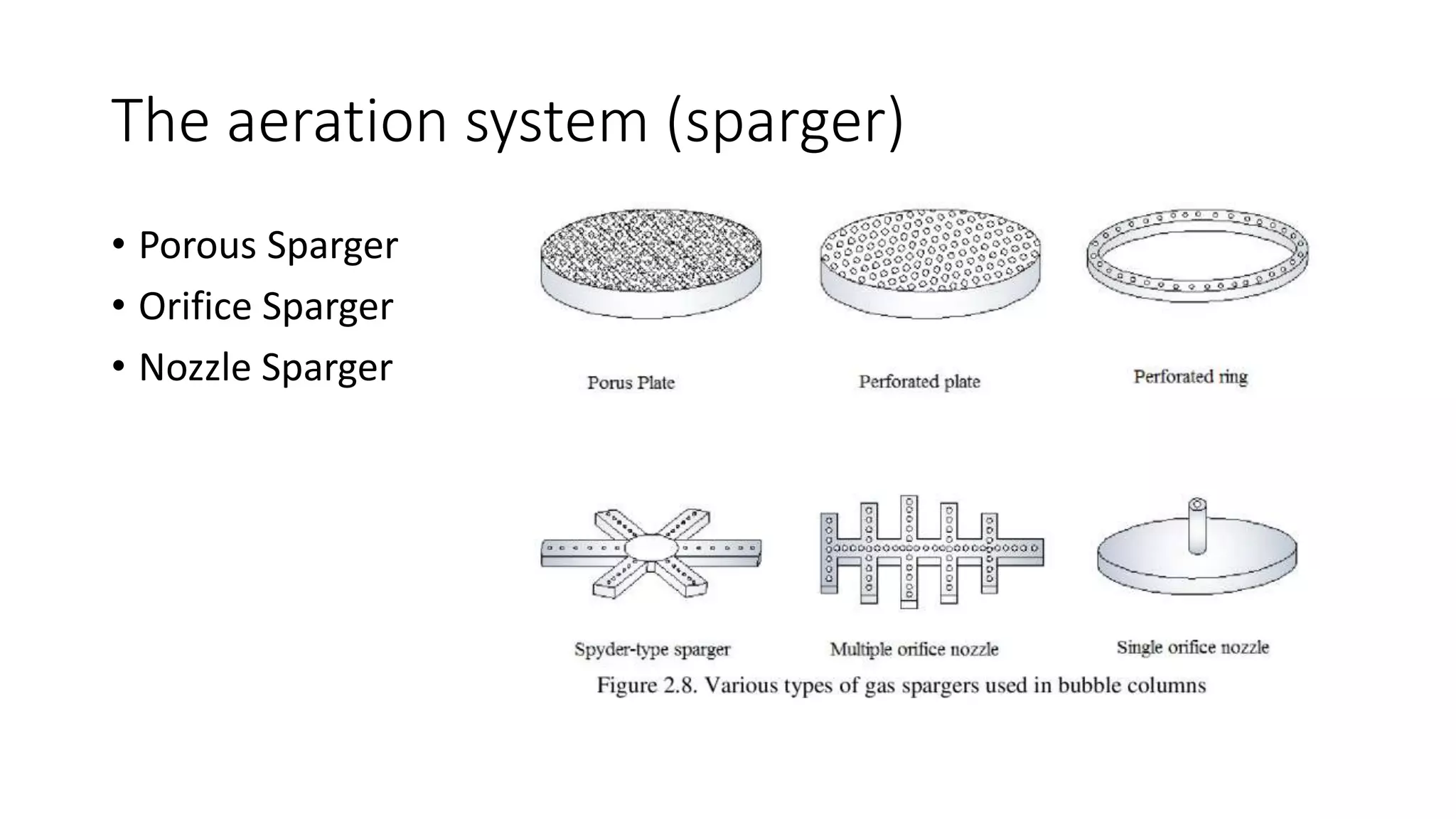

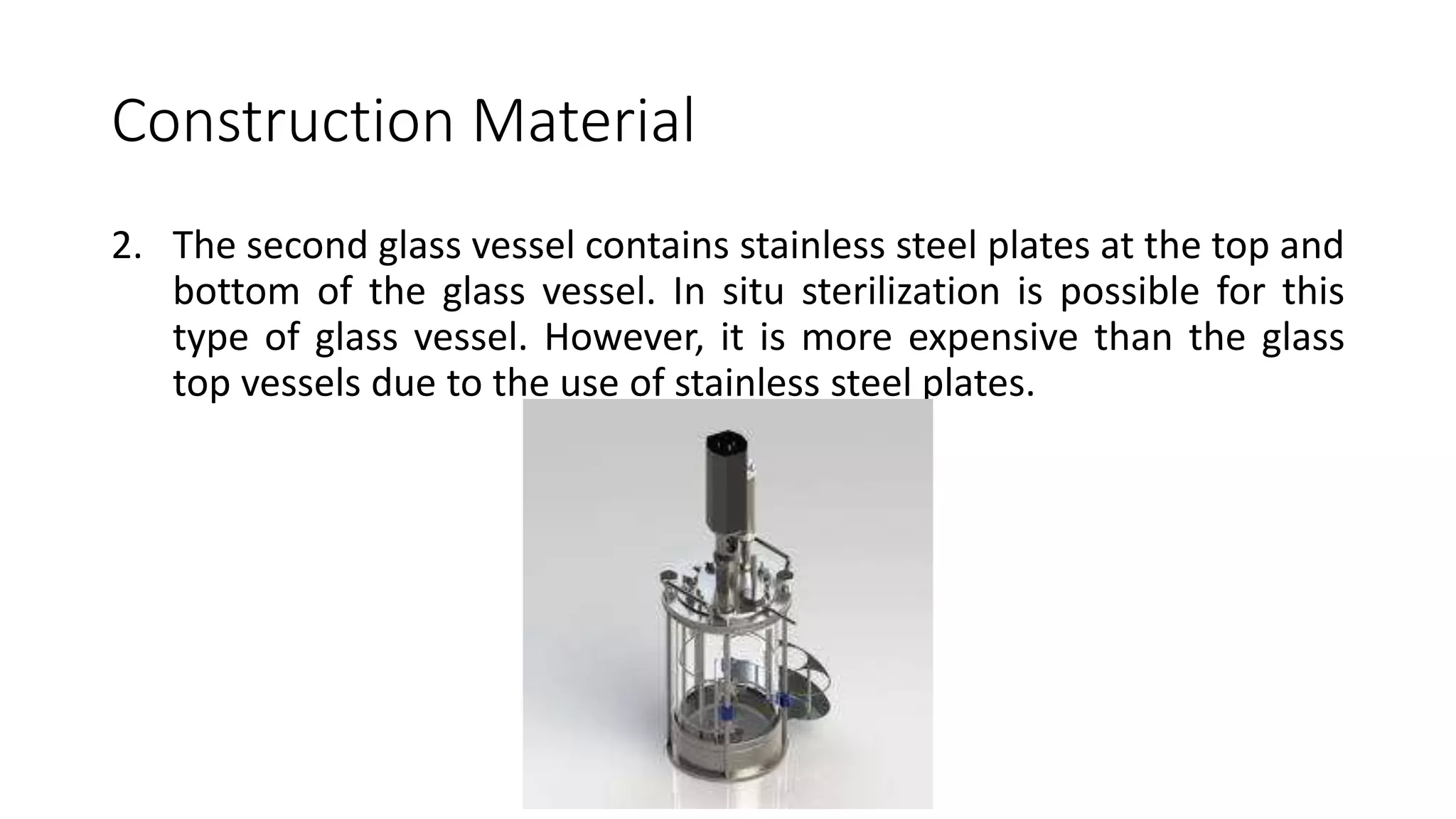

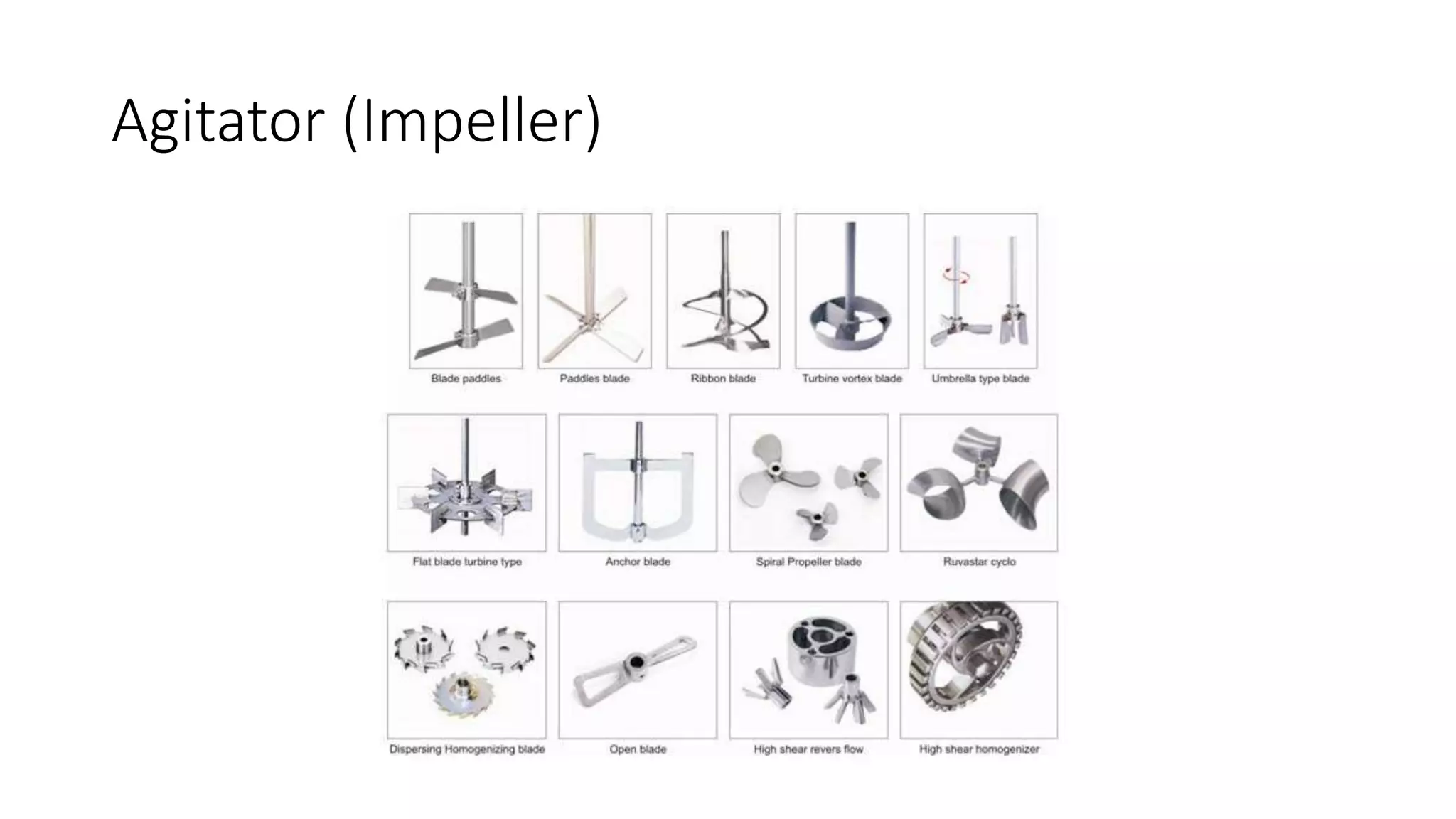

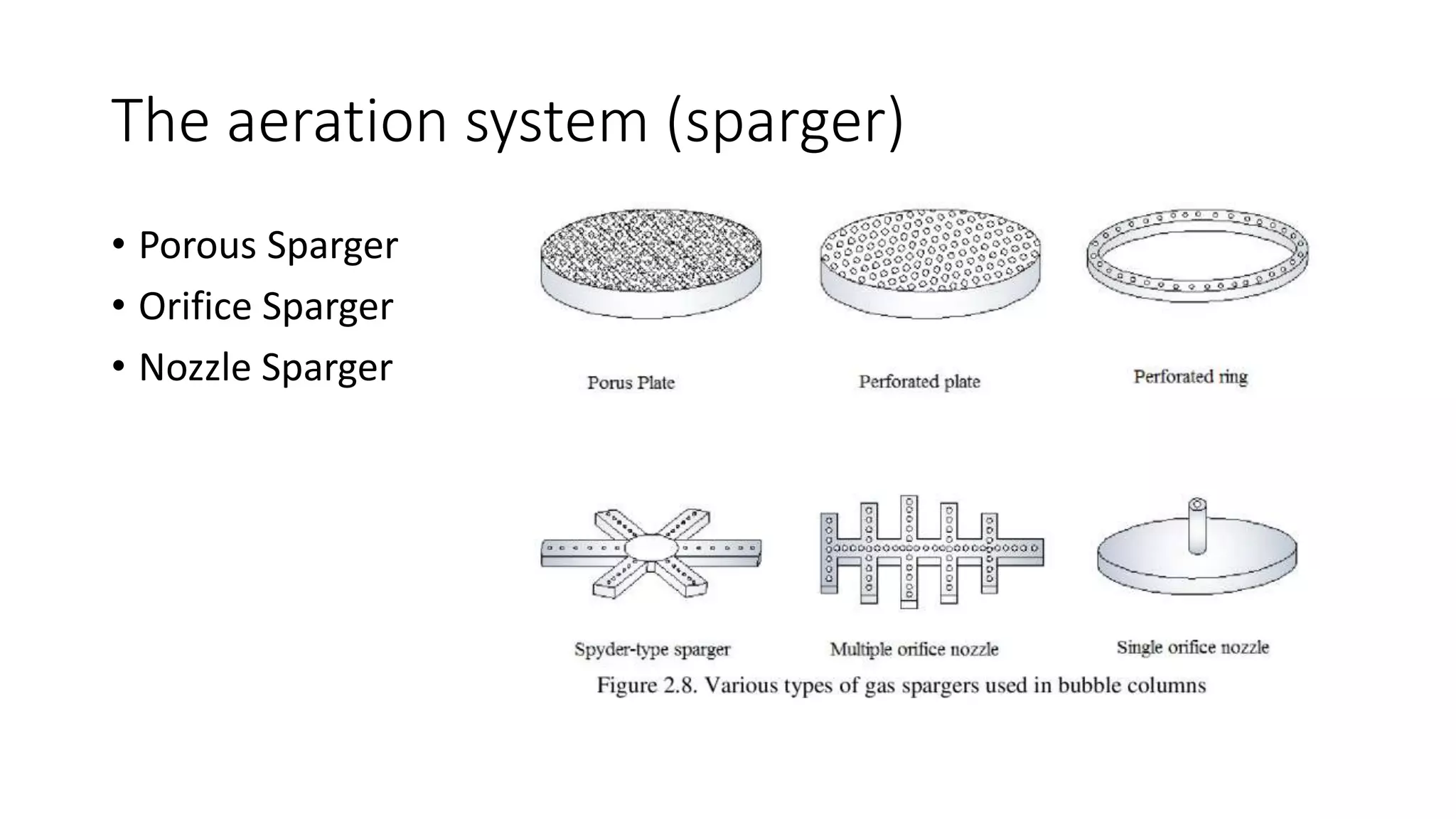

Fermenters come in two main glass designs - a flat-bottomed glass vessel with a glass top plate that is autoclaved for sterilization, or a vessel with stainless steel plates on the top and bottom allowing for in-situ sterilization but at a higher cost. Temperature control is needed during fermentation to manage heat produced from microbial reactions and agitation, and components like impellers, baffles, spargers, and pH sensors help control aeration, mixing, and chemical levels in the fermenter.