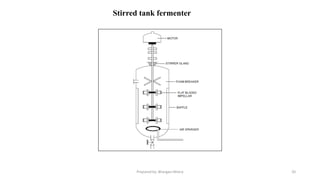

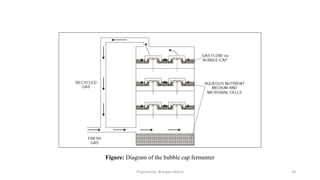

Fermenters, also known as bioreactors, are specially designed vessels used for growing microorganisms in a controlled environment. They allow microorganisms to grow in large volumes of highly nutritive culture media and convert feed into the desired end product through fermentation. Fermenters must provide optimal conditions for growth and production while minimizing power consumption and contamination risks. They consist of components like the fermenter vessel, heating/cooling system, aeration system, agitator, sparger, baffles and controls for monitoring environmental factors. Common types of fermenters include stirred tank, airlift, tower and bubble cap designs which utilize different mechanisms for mixing and oxygenating the culture broth.

![FERMENTERS

PREPARED BY:

Bhargavi Mistry

[M. Pharm (Pharmaceutics)]](https://image.slidesharecdn.com/fermenters-230131143201-c4473670/85/Fermenters-pdf-1-320.jpg)