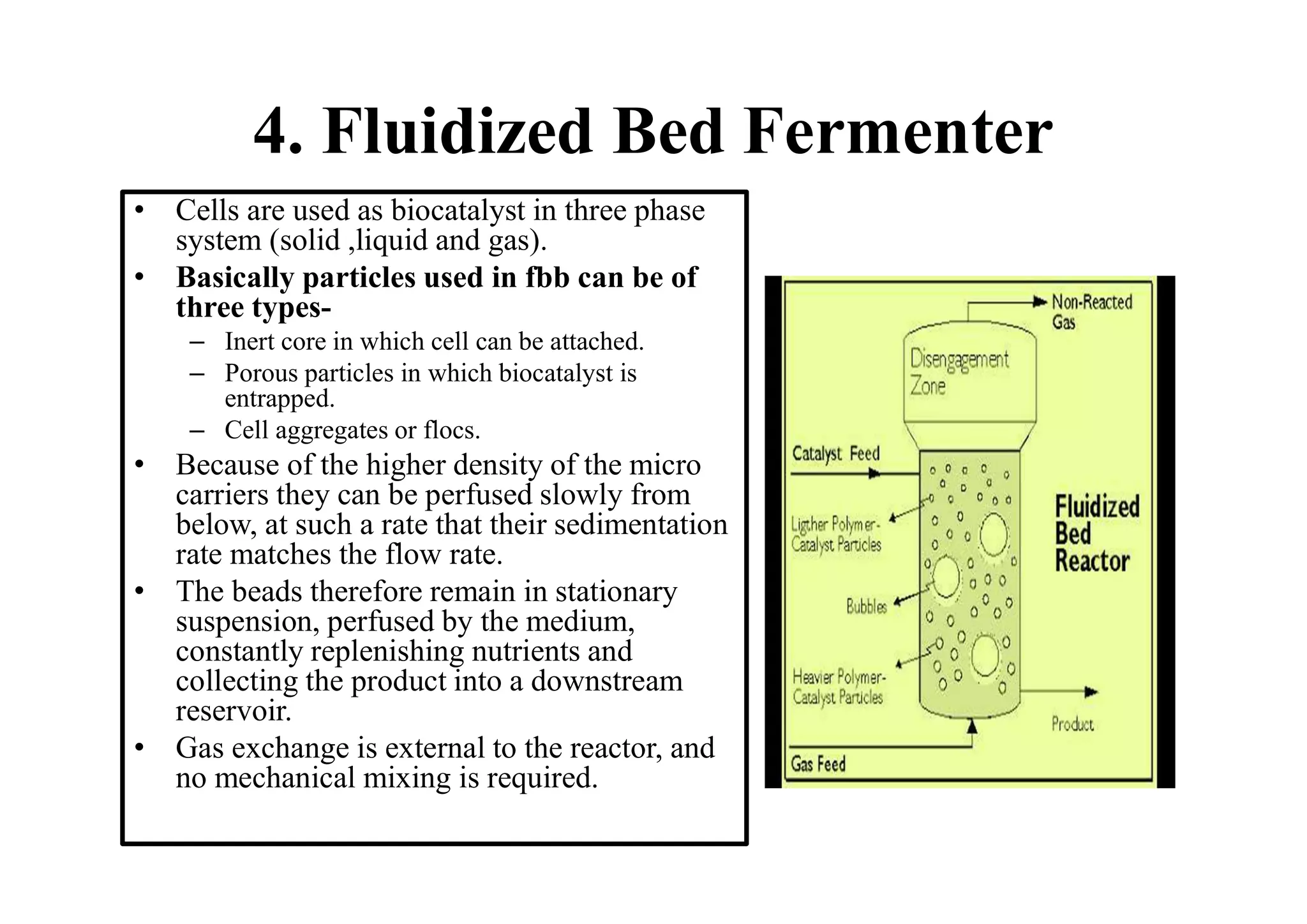

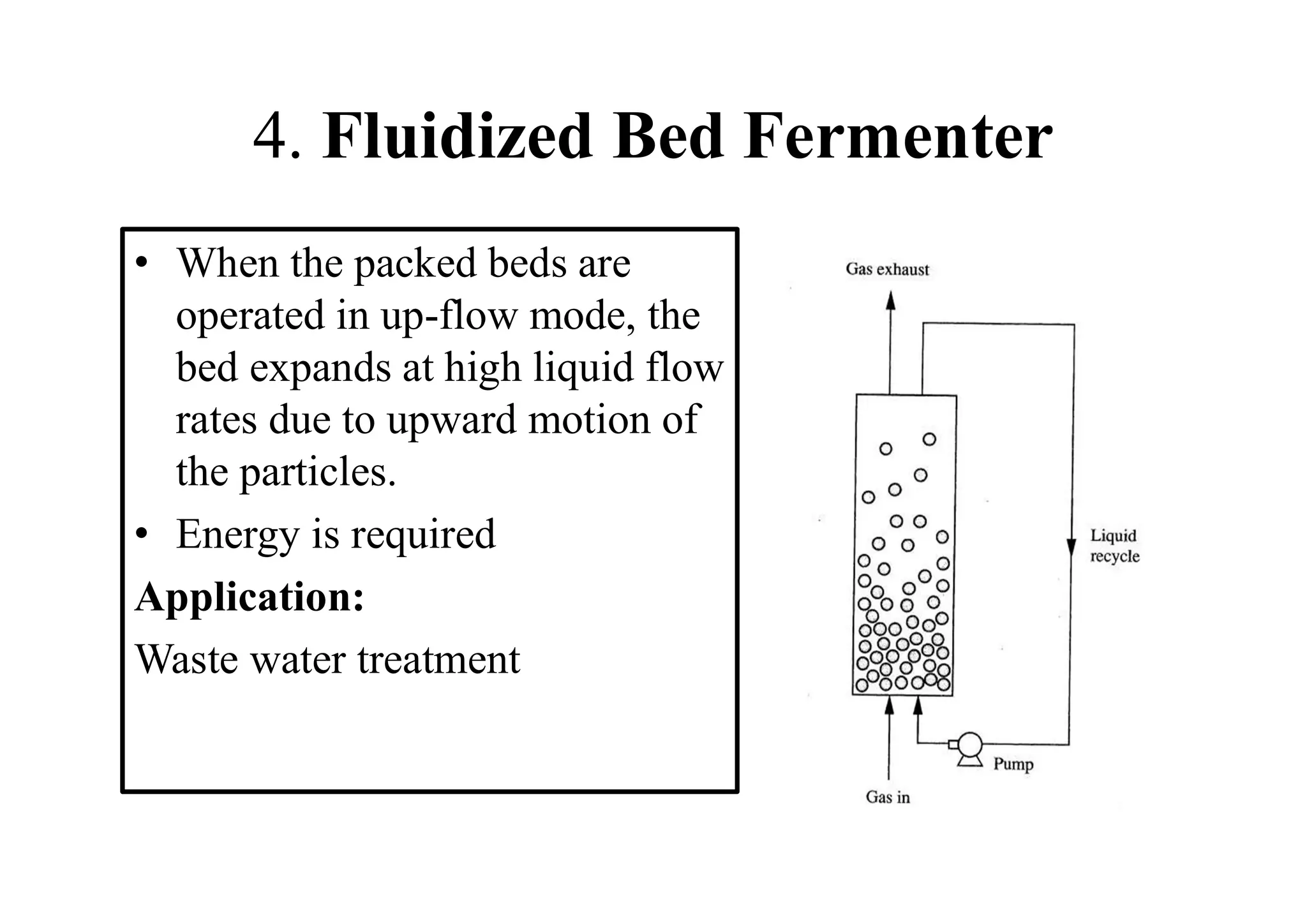

This document provides information on different types of bioreactors. It begins by defining a bioreactor as a vessel that enables microbial growth while preventing contamination and providing necessary conditions. It then describes six main types of bioreactors: stirred tank, bubble column, airlift, fluidized bed, packed bed, and photobioreactor. Each type is discussed in 1-2 paragraphs, outlining its mixing method, applications, and basic design. Key parts of bioreactors like temperature control, pH control, and foam control systems are also summarized. The document concludes by stating that bioreactors must carefully control factors like oxygen delivery, agitation, temperature, pH, and foam to optimize microbial production.