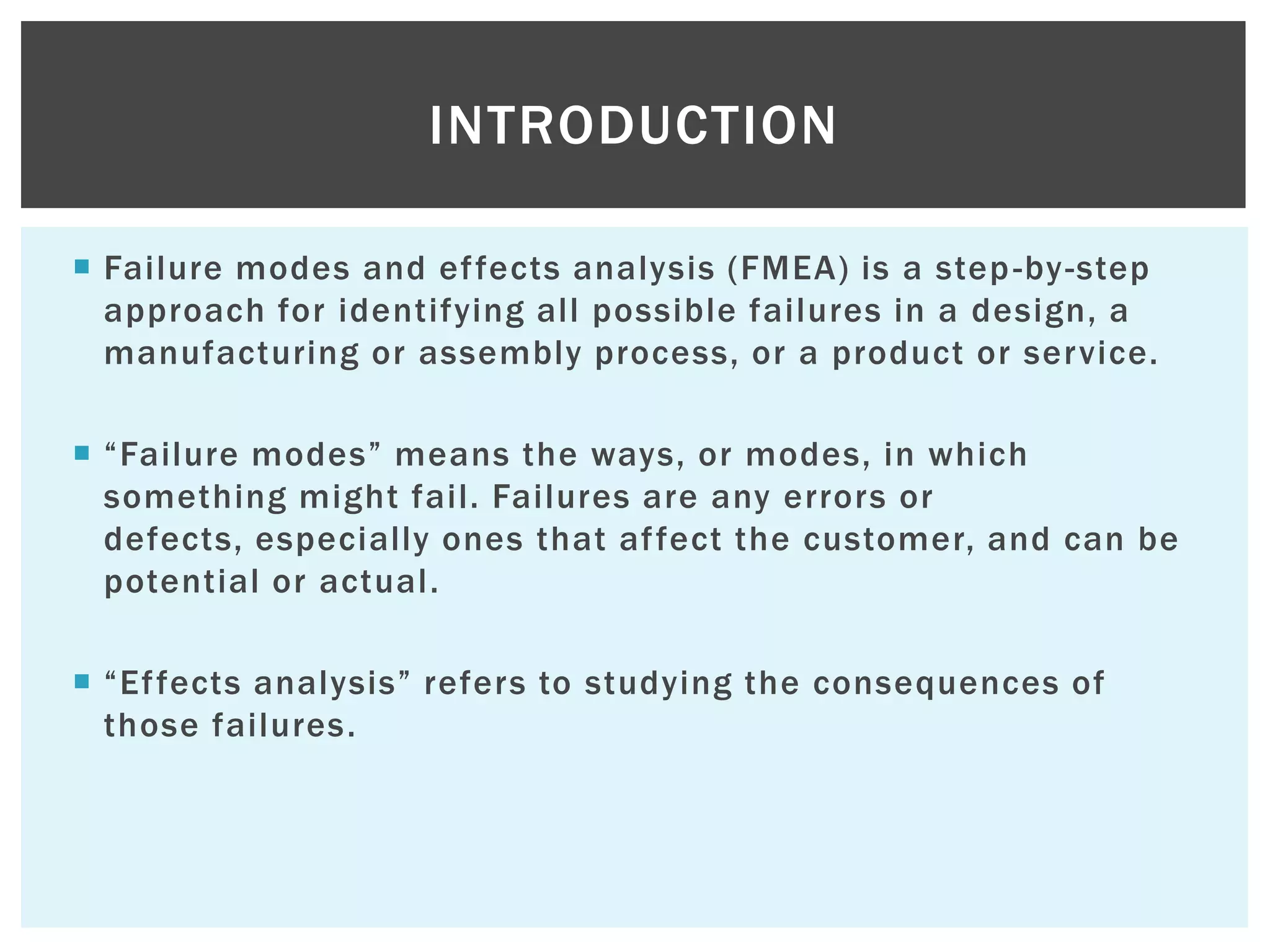

The document discusses failure mode and effects analysis (FMEA). It provides information on:

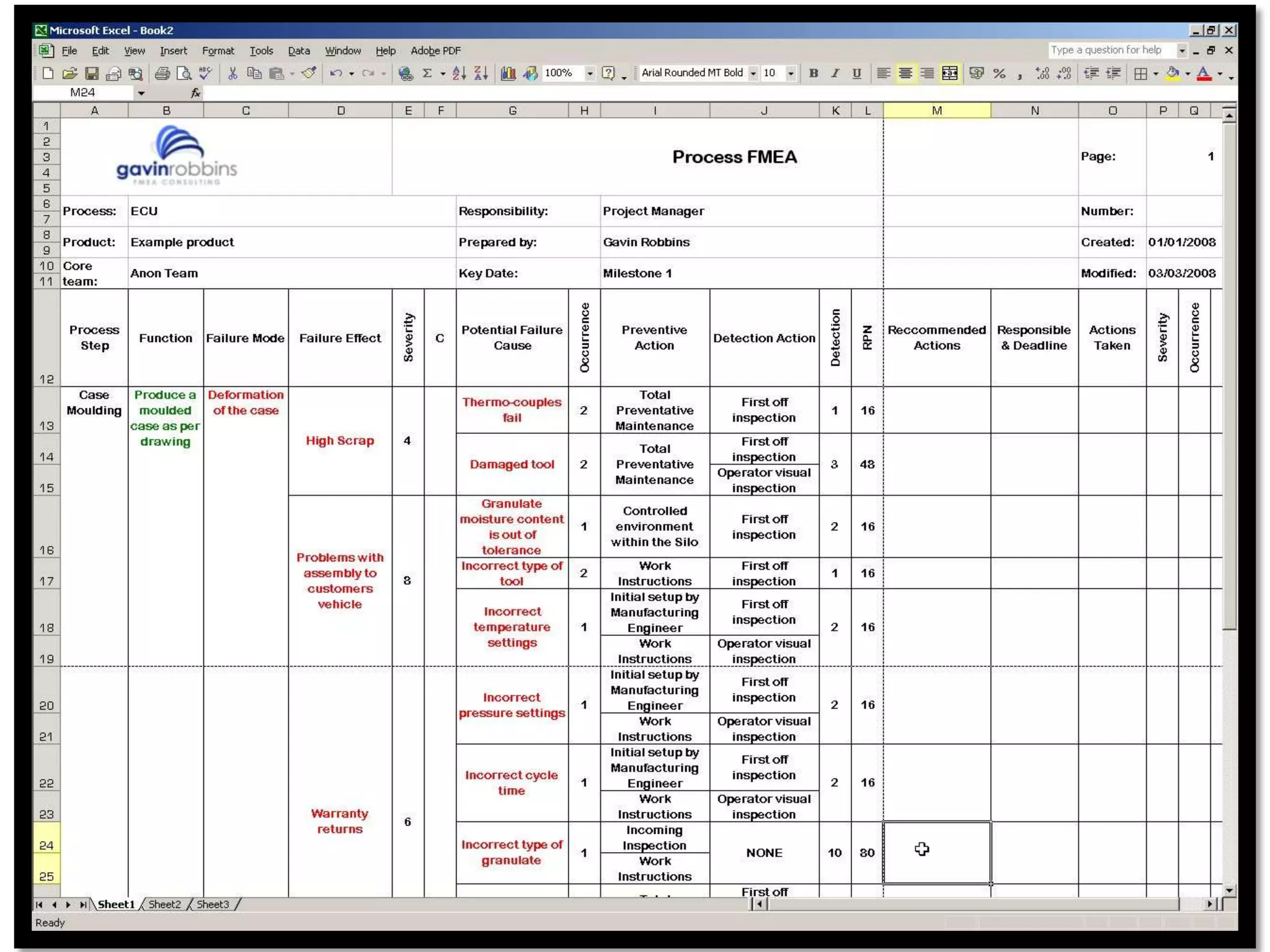

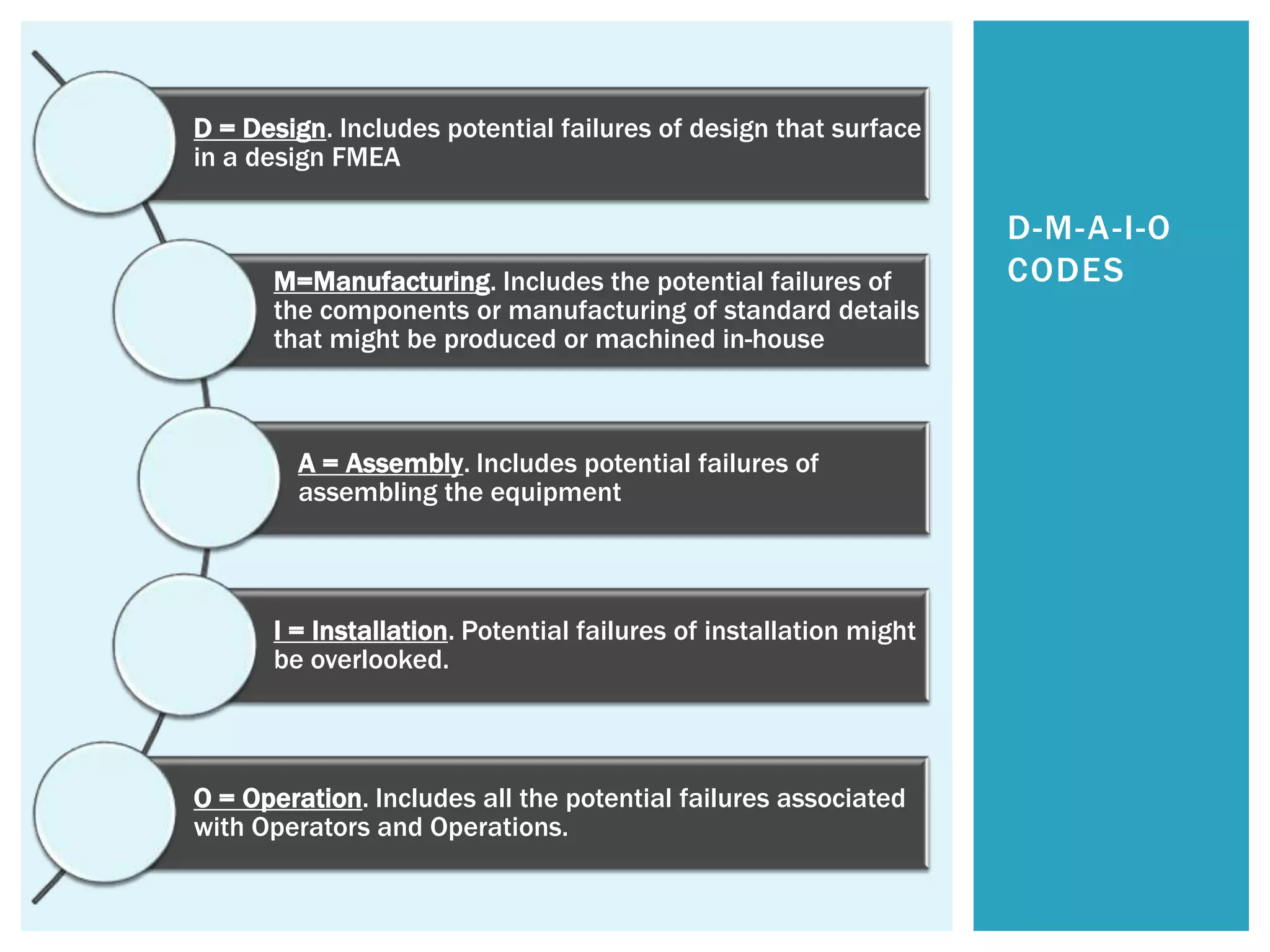

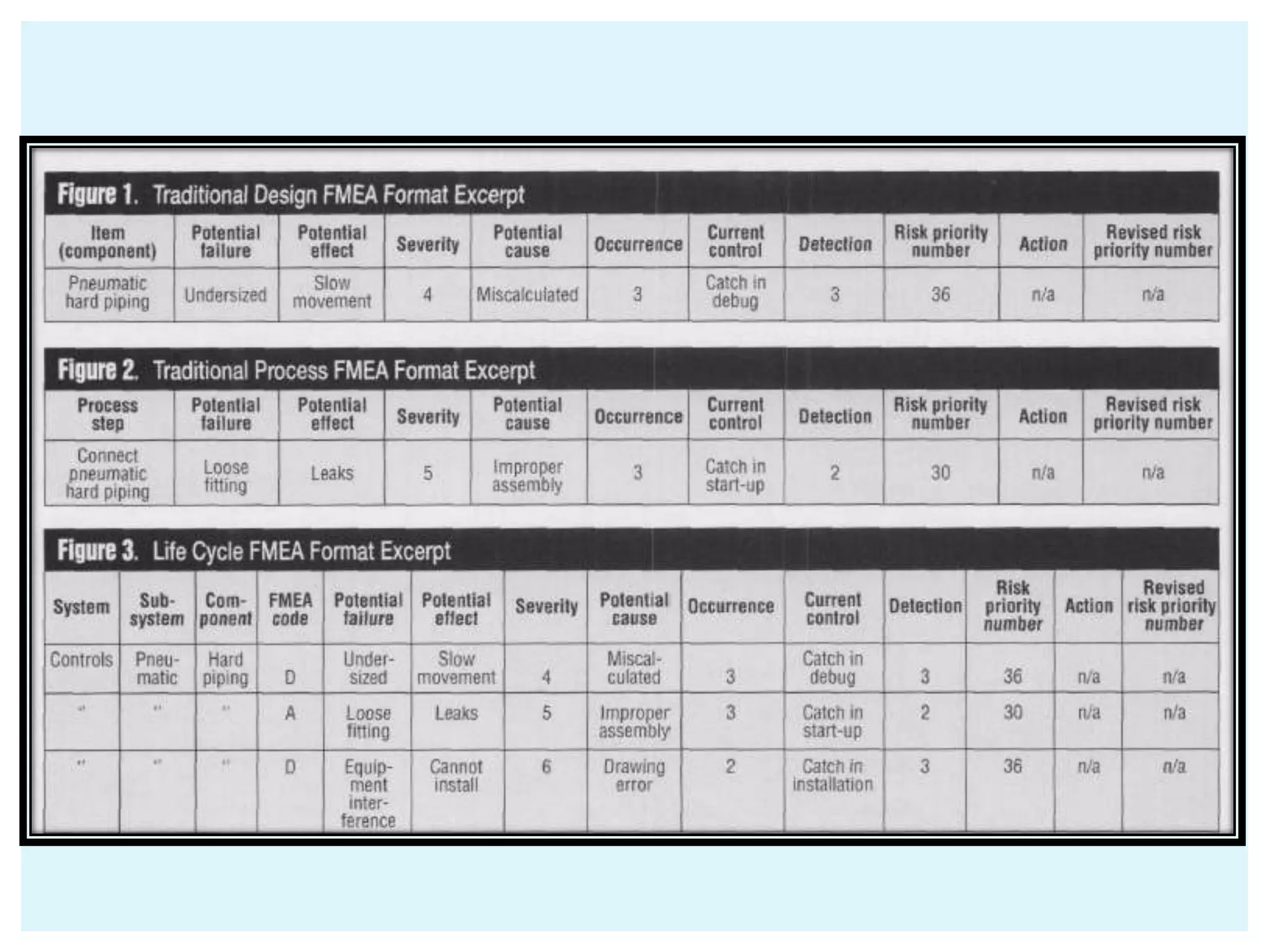

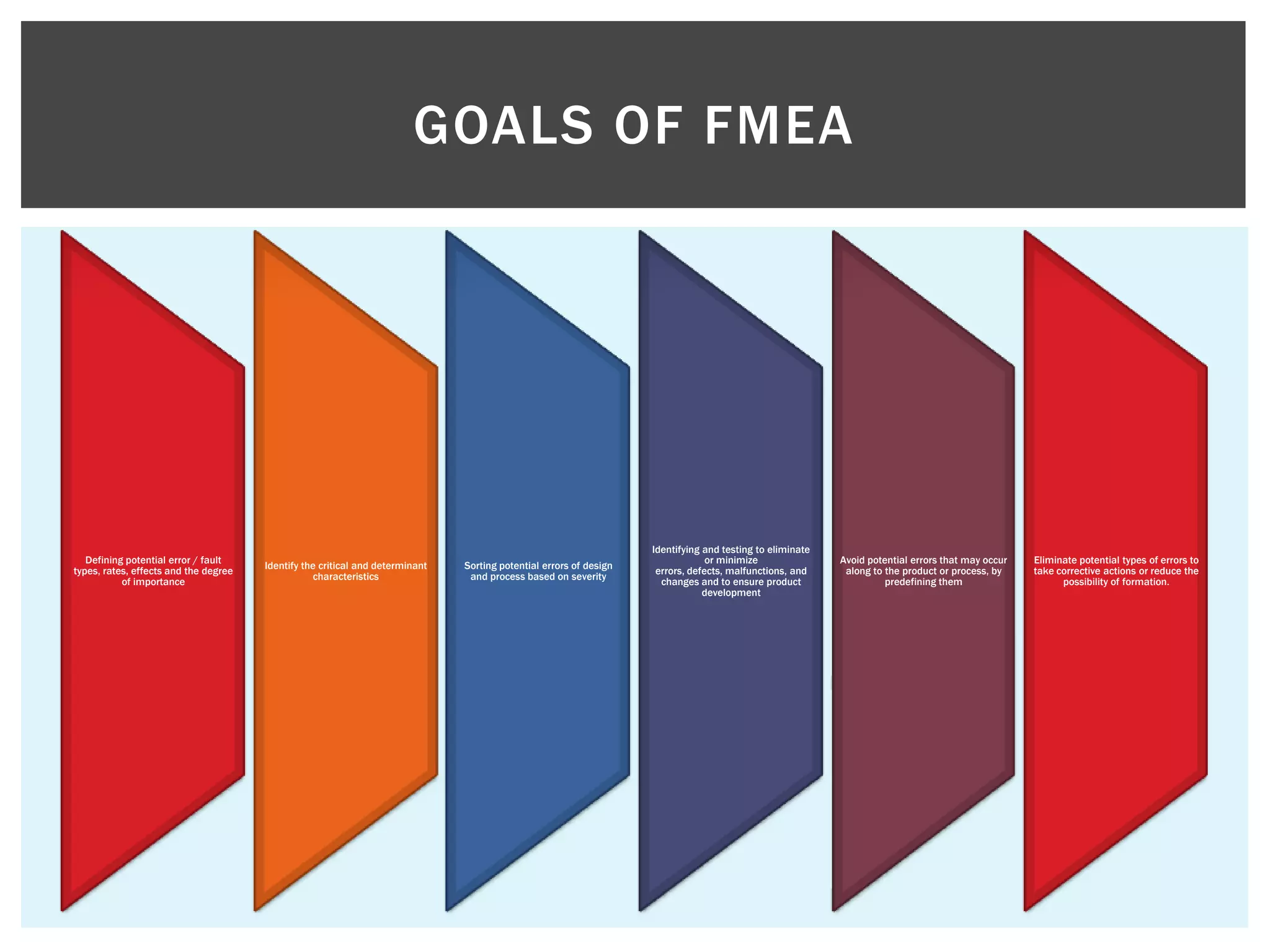

- The types of FMEA including system, design, process, and service FMEA.

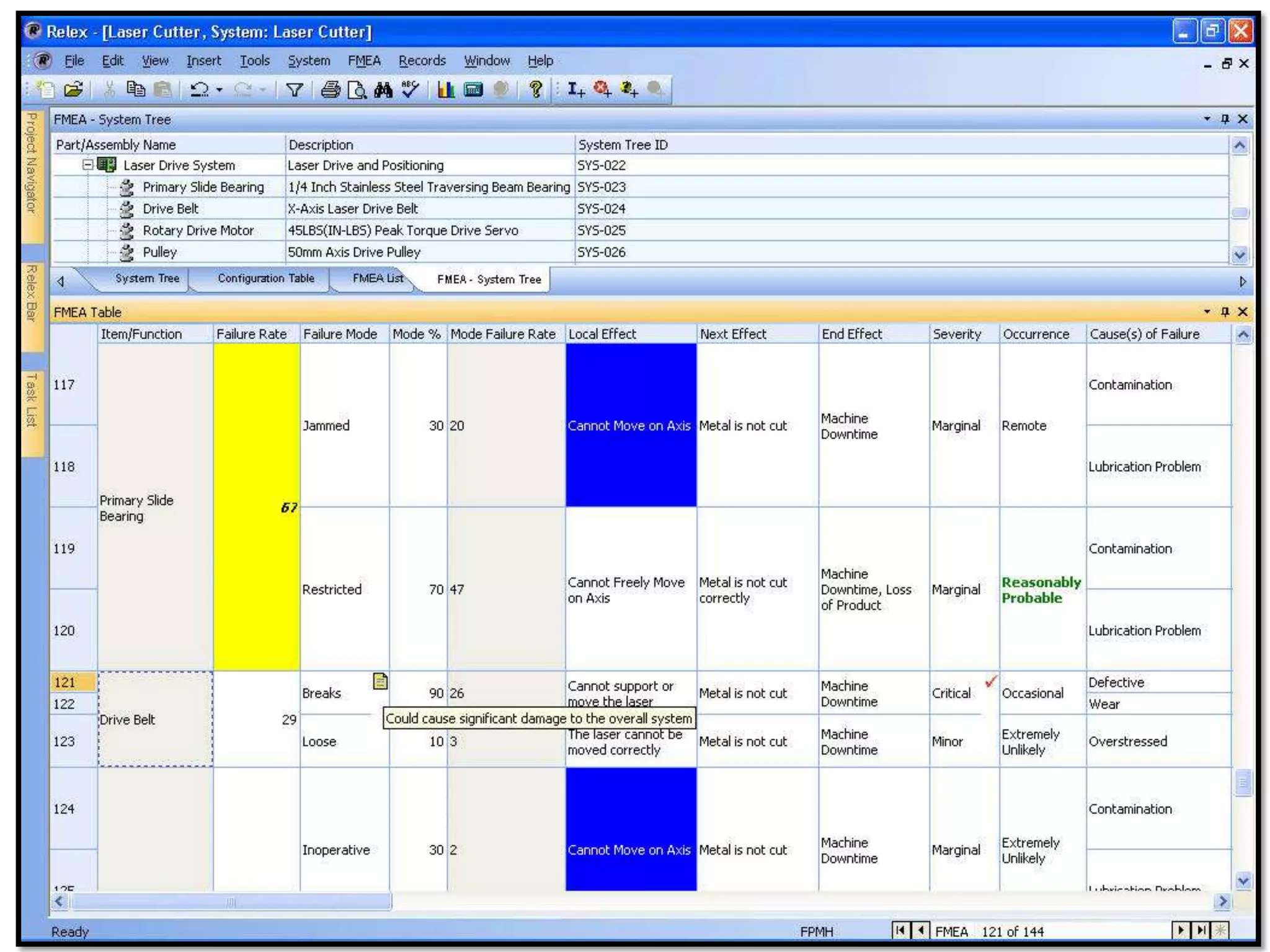

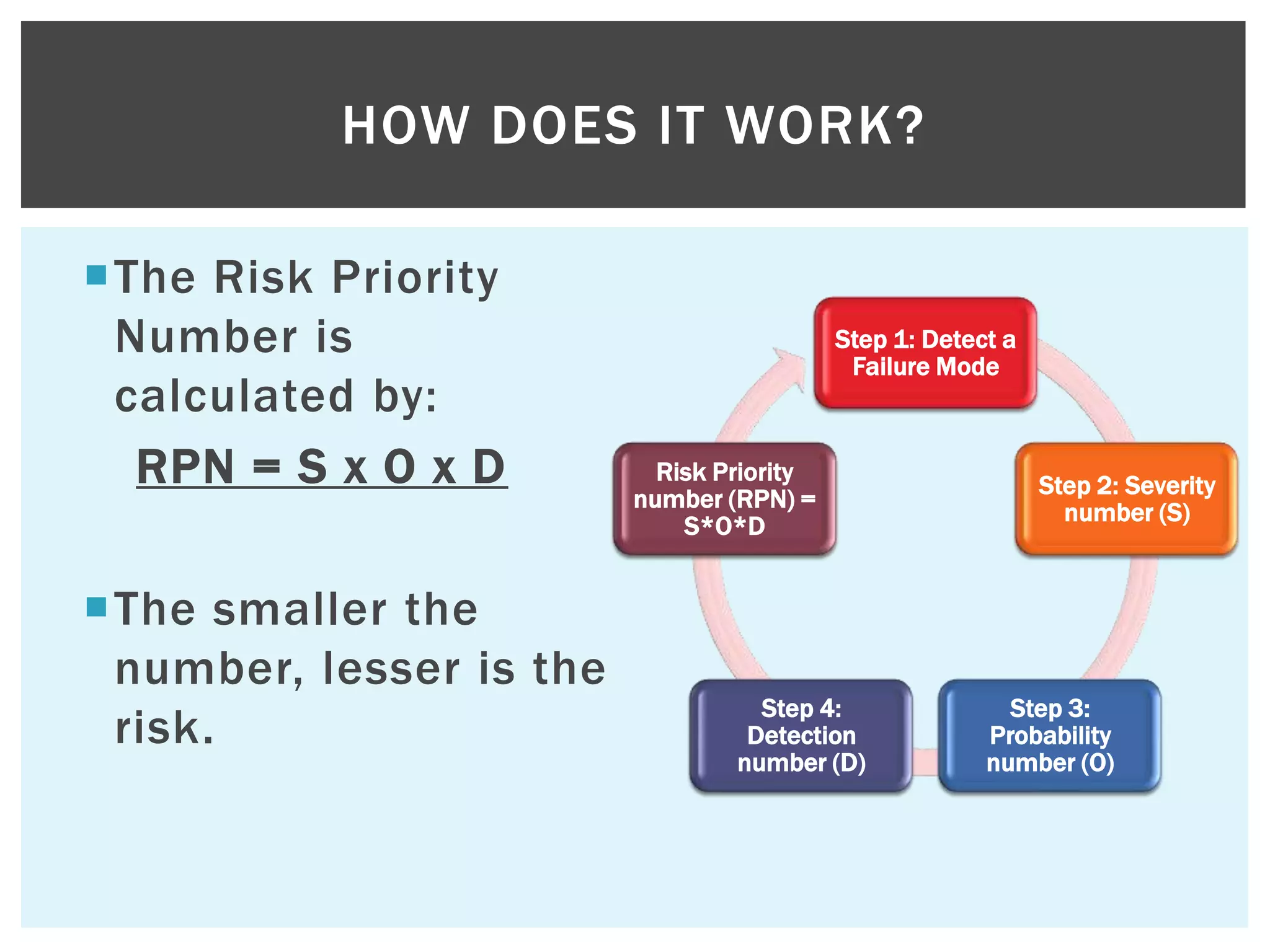

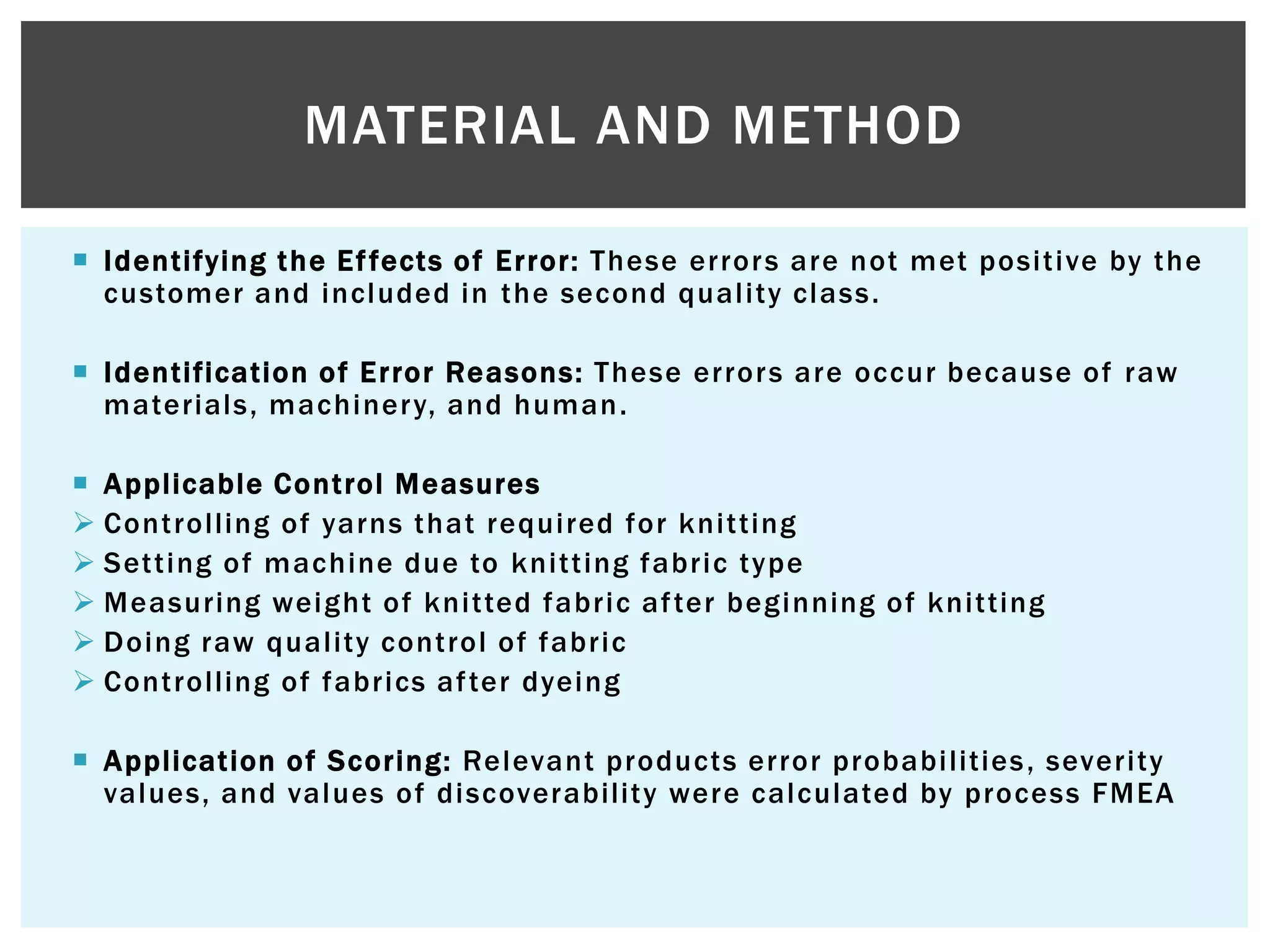

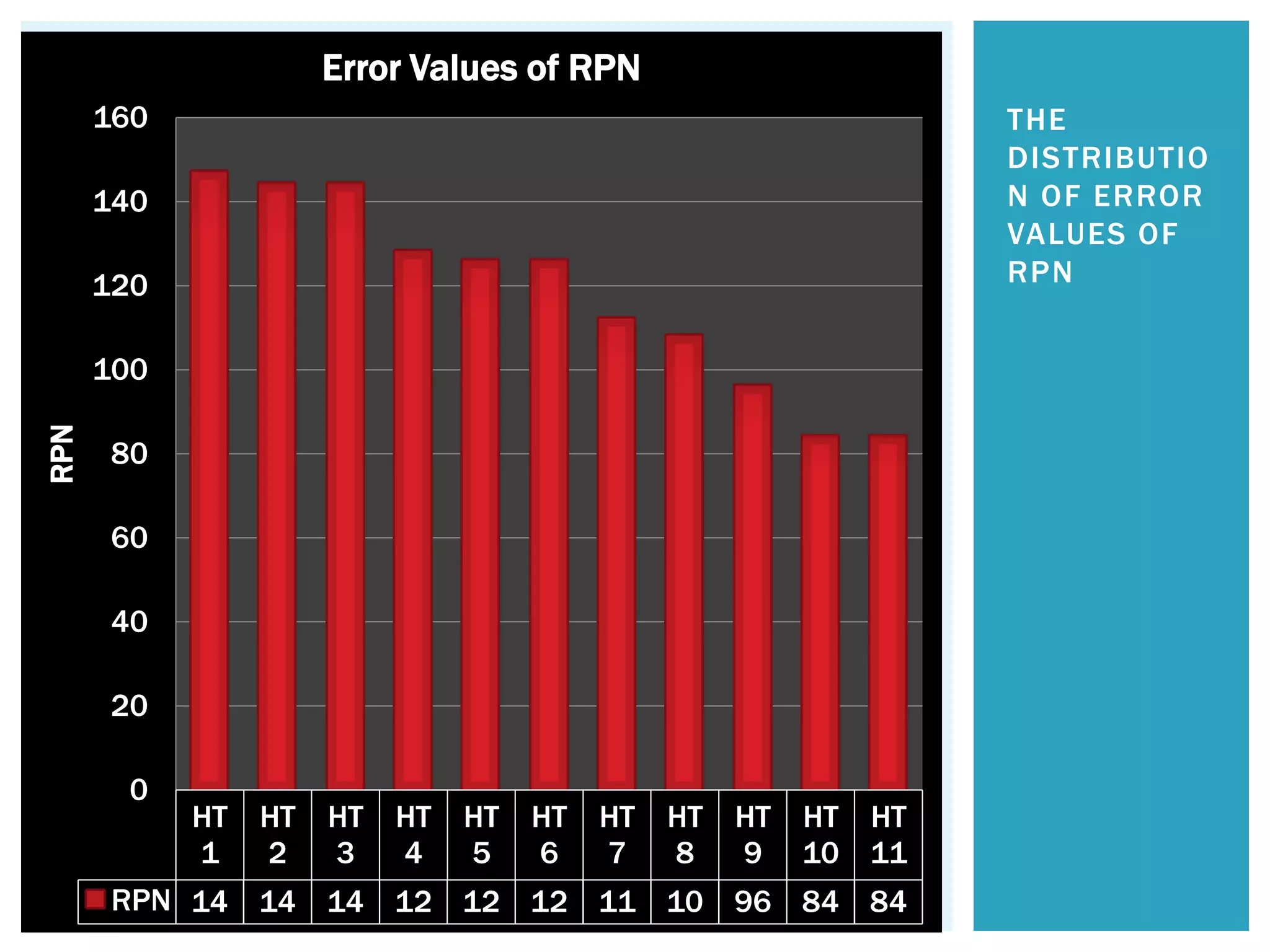

- How FMEA works by identifying potential failure modes, analyzing their effects, and prioritizing them according to severity, occurrence, and detection.

- When FMEA should be used including during design, improvement planning, and when analyzing process or product failures.

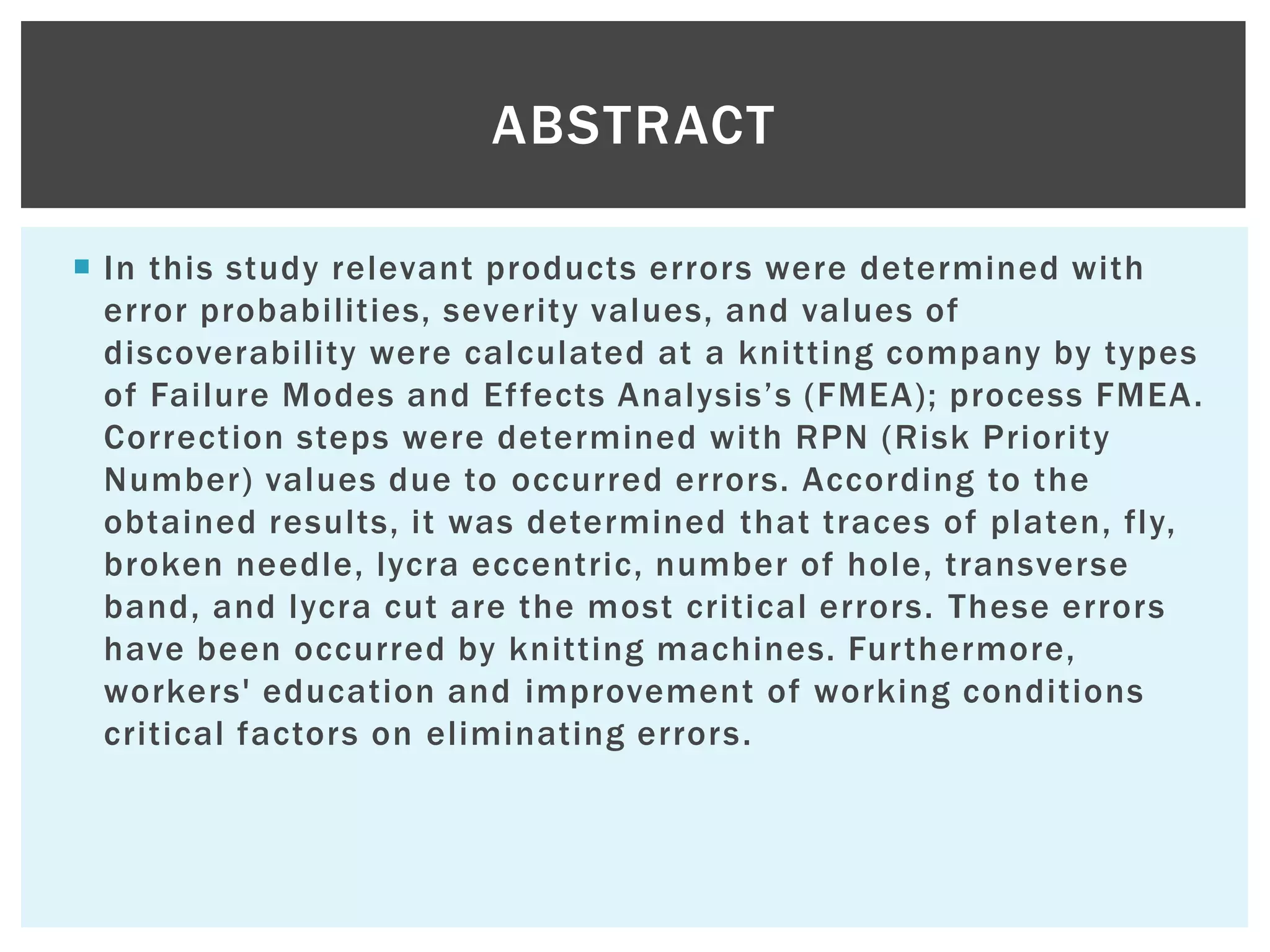

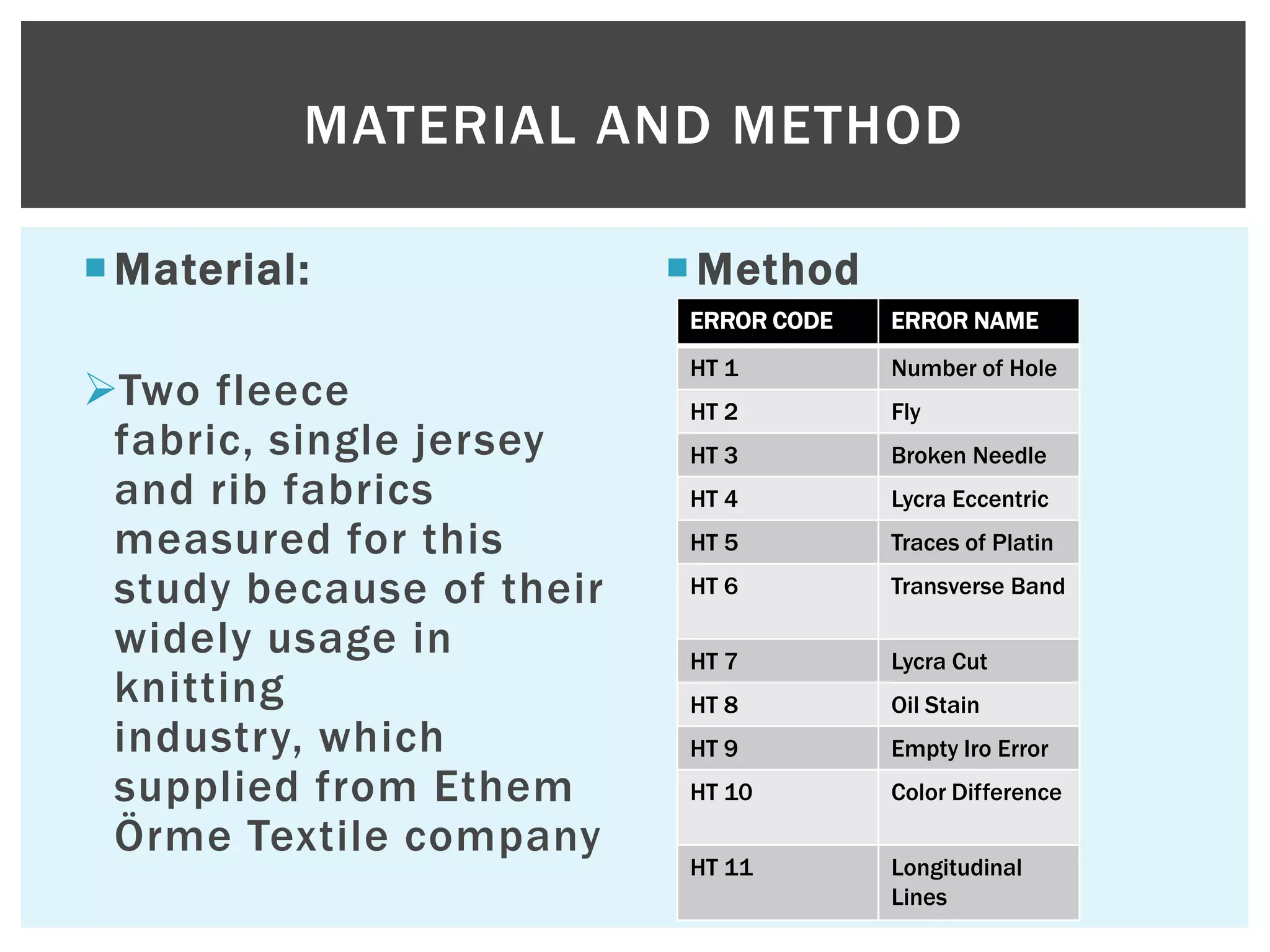

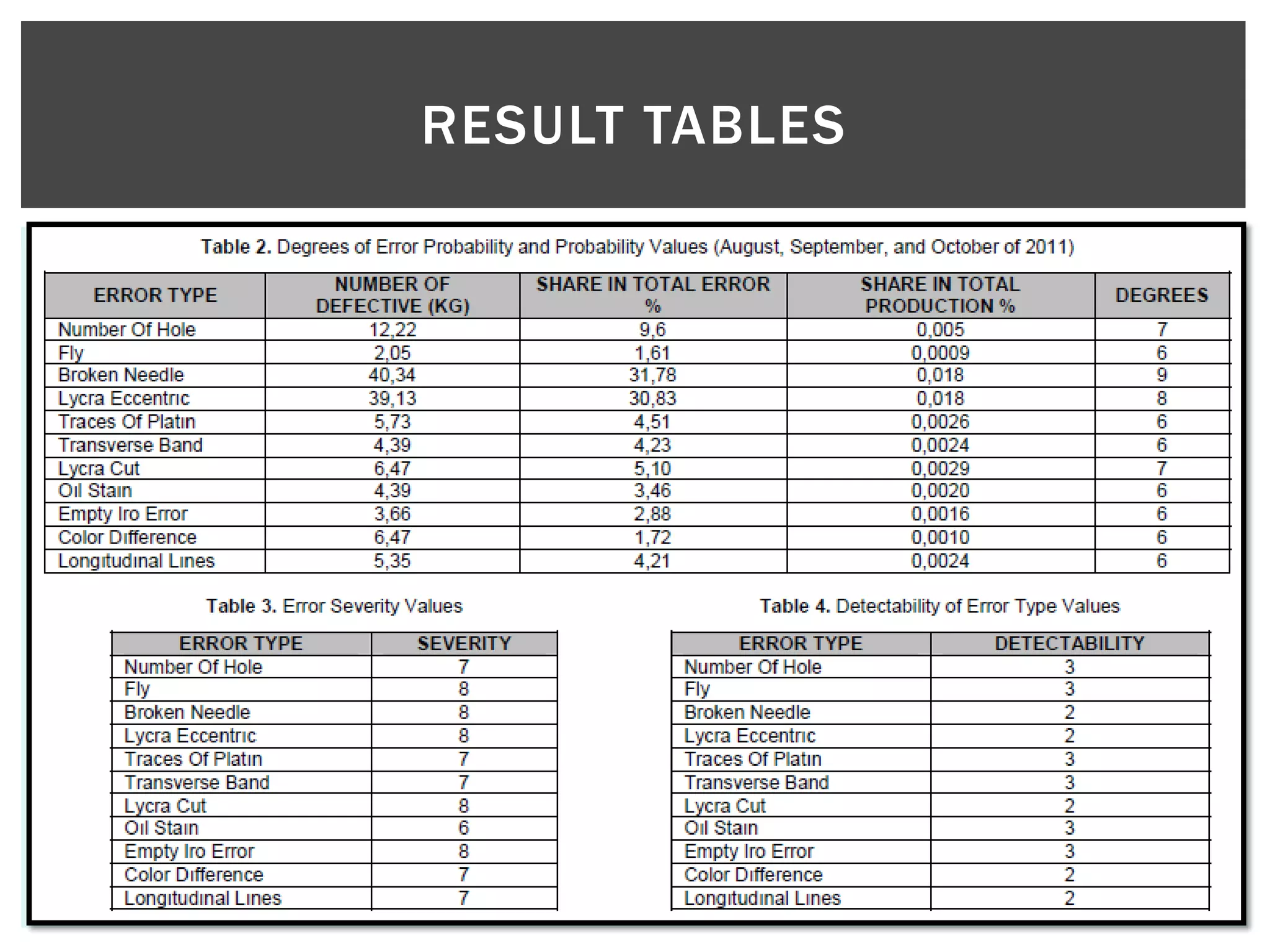

- A case study on how FMEA was used to analyze errors in a knitting industry and identify critical errors to focus corrective actions on.