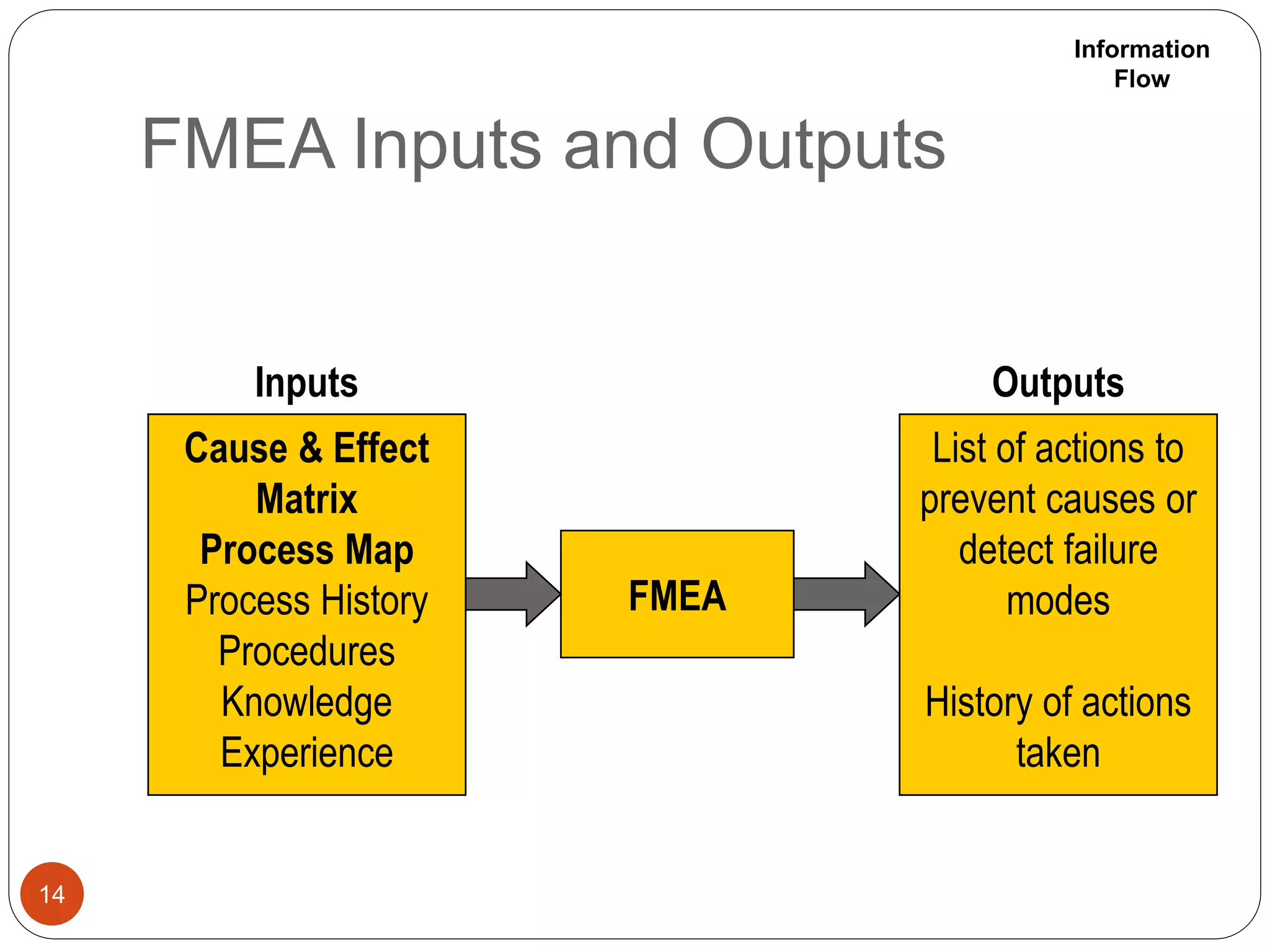

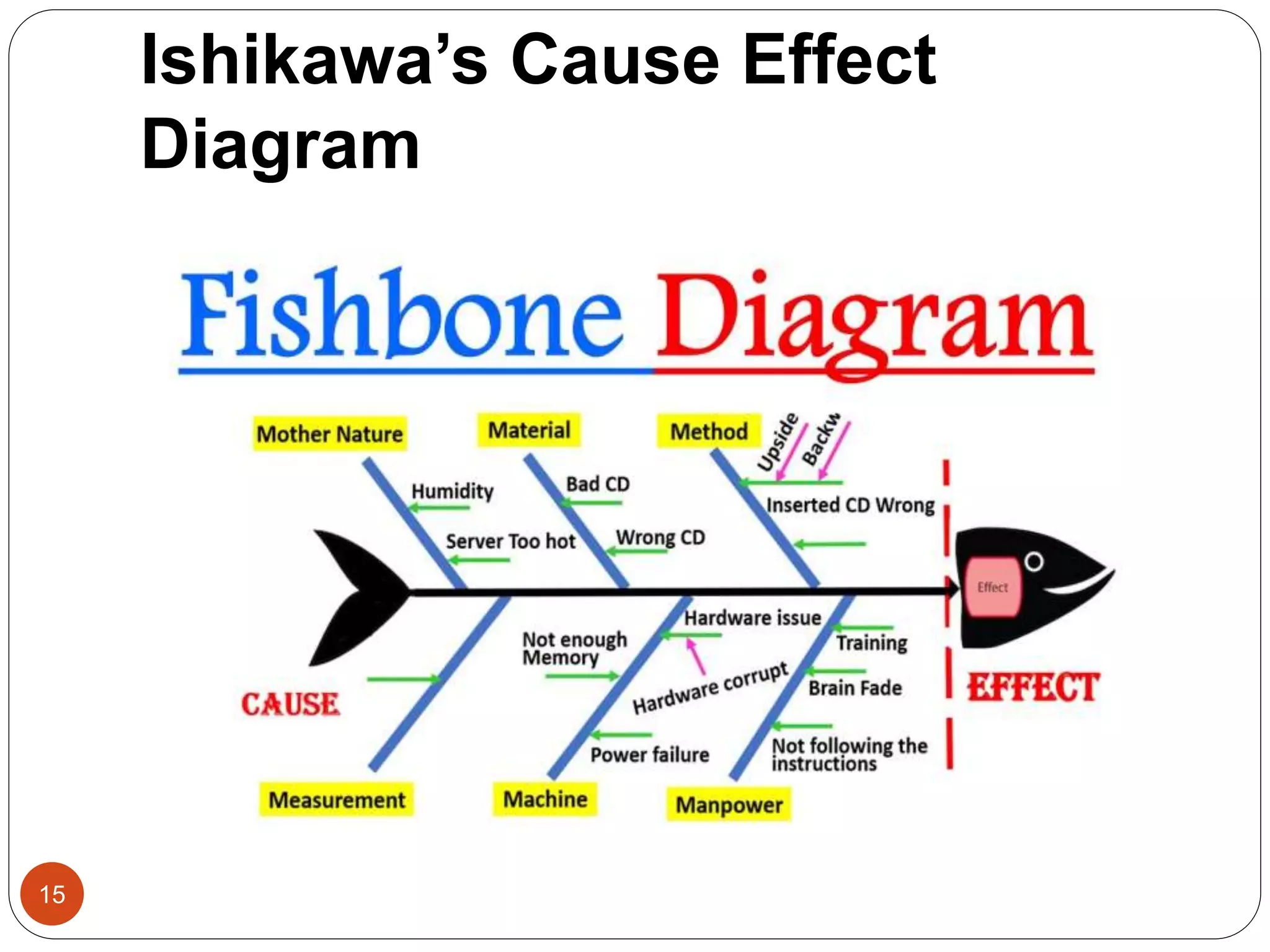

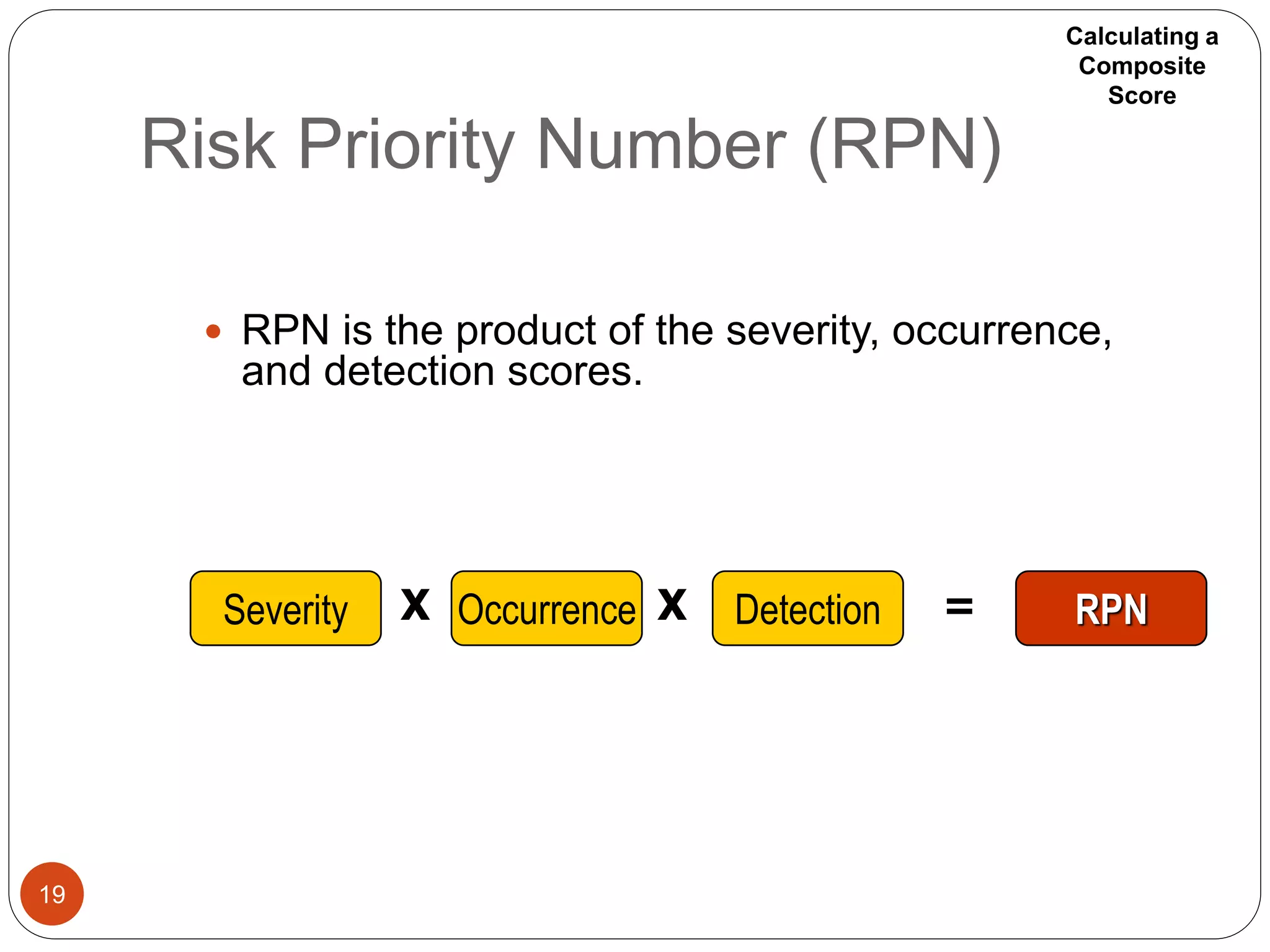

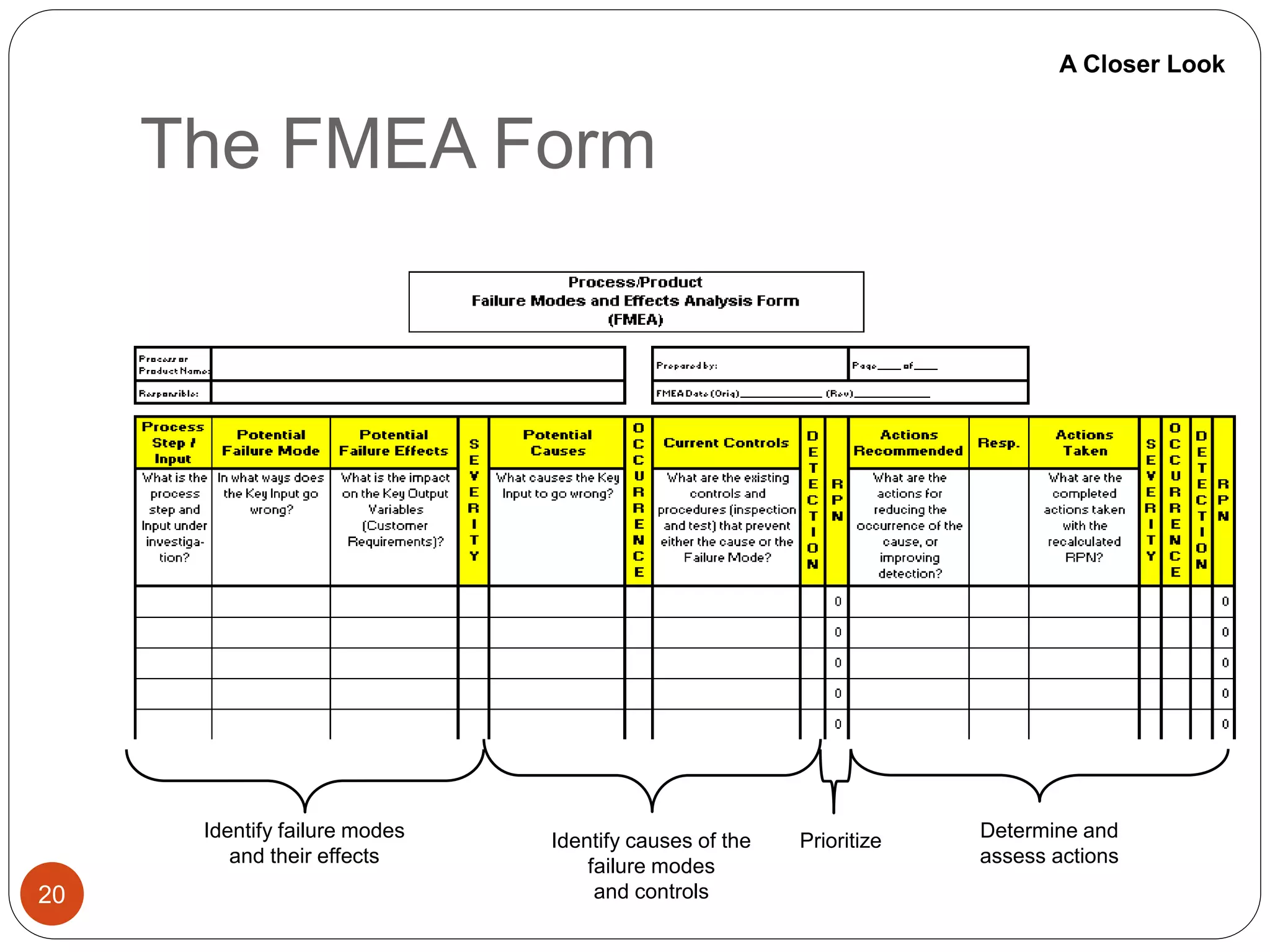

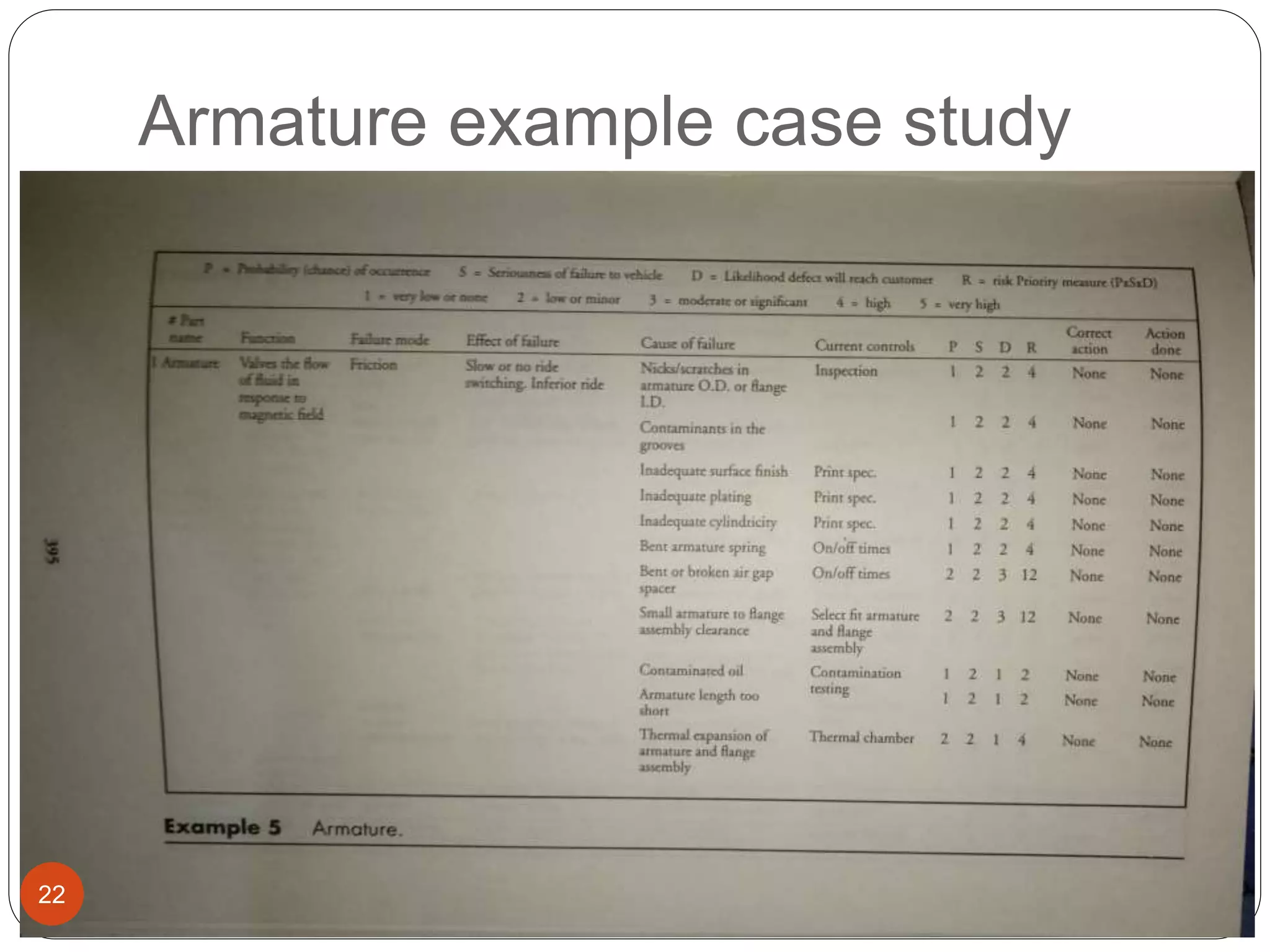

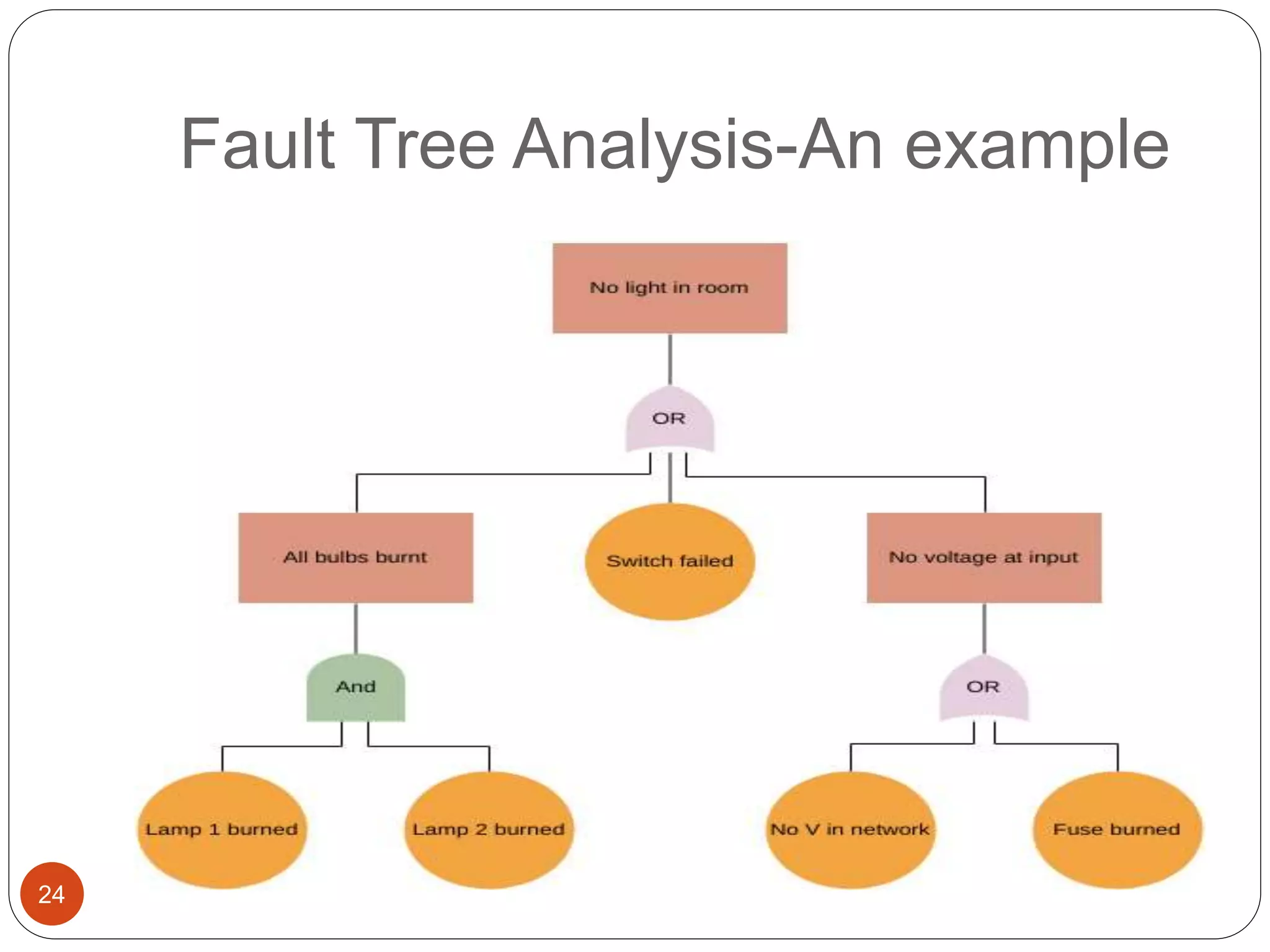

This document provides an overview of failure mode and effects analysis (FMEA). It describes FMEA as a tool to identify potential failure modes, estimate the risk associated with failures, and prioritize actions to address high-risk failures. The document outlines the FMEA process, which involves identifying failure modes and their causes and effects, then calculating a risk priority number to prioritize issues. It also discusses design and process FMEAs and when each is used. Finally, it reviews how FMEA relates to and can be used along with other process analysis tools.