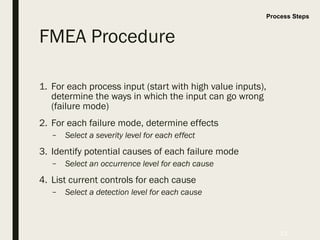

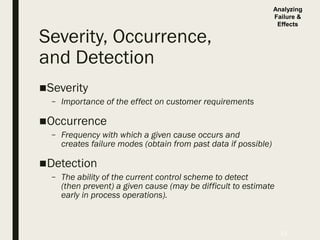

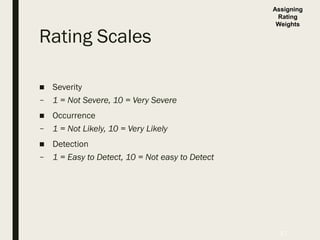

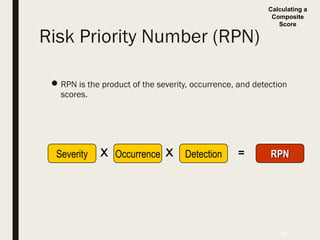

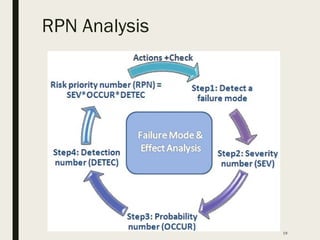

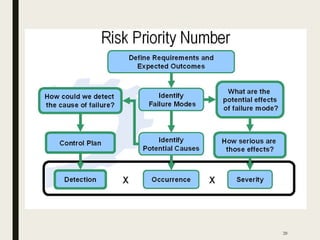

Failure Modes Effect Analysis (FMEA) is a methodology to identify and eliminate potential failures early in development. It involves a team identifying ways a process can fail, estimating risk from causes, and prioritizing actions. There are two types - design FMEA analyzes product design, while process FMEA analyzes manufacturing processes. The team rates the severity, occurrence, and detection of failures and causes to calculate a Risk Priority Number and identify high risk items.