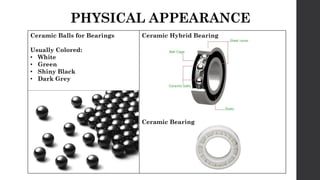

Ceramic ball bearings, made with silicon nitride ceramic balls, offer significant advantages over steel bearings, including higher speed, reduced friction, and longer service life. They are nonconductive, lower maintenance costs, and can operate at cooler temperatures, making them suitable for multiple applications such as wind power and high-speed machinery. While they may have a higher initial cost, their durability and efficiency lead to overall savings in maintenance and production.