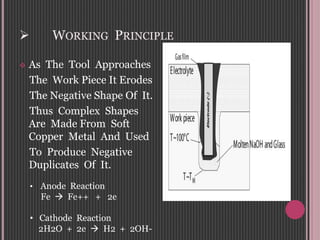

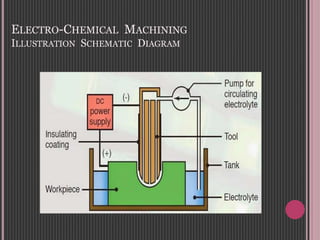

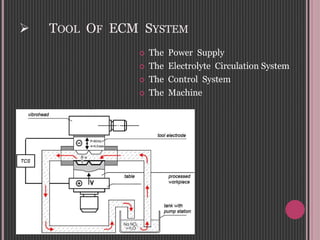

Electrochemical machining (ECM) is a non-traditional machining process that removes metal by electrochemical dissolution rather than mechanical forces. ECM was first introduced in 1929 and has since been used for complex machining applications. In ECM, an electric current is passed between an electrode tool and a conductive workpiece submerged in an electrolyte solution. This causes metal ions from the workpiece to dissolve into the solution, machining the workpiece without physical contact. ECM can machine hard metals and complex shapes more accurately than traditional methods, but requires specialized equipment and produces hazardous waste. Common applications include machining turbine blades and rifle barrels.

![ELECTRO CHEMICAL MACHINING

[ECM]

SUBJECT : MANUFACTURING ENGINEERING - 3

PREPARED BY : JAYKUMAR R. SONAR

ENROLL. NO : 149740319047

GUIDED BY :

MR. D . T . PATEL](https://image.slidesharecdn.com/electrochemicalmachining-160731093233/85/Electrochemical-machining-1-320.jpg)