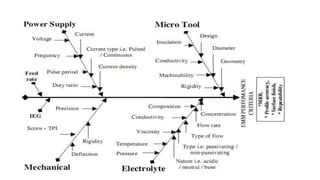

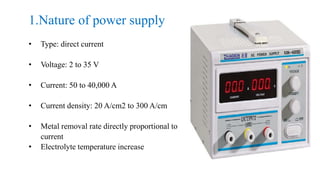

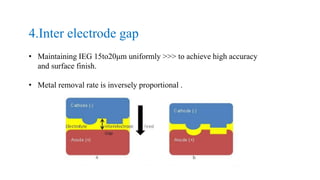

This document discusses parameters that affect the surface roughness of electrochemically machined surfaces. It outlines several key parameters including: the type of power supply used, duty cycle, voltage, inter-electrode gap, electrolyte concentration, temperature and flow rate, the type of tool used, and the micro-tool feed rate. Maintaining an optimal inter-electrode gap of 15-20 micrometers and using a duty cycle of 0.3 were found to produce the best surface roughness. The concentration of the electrolyte and keeping the temperature below 50 degrees Celsius also impacted surface quality.

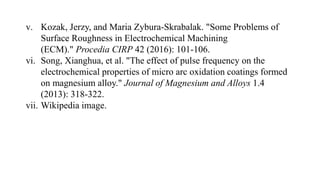

![Used in Russia Ref.[7]](https://image.slidesharecdn.com/ecmparameters-171122073750/85/Electro-chemical-machining-parameters-2-320.jpg)

![Affecting parameters of electro chemical machined

surface

1. Nature of power supply

2. duty cycle

3. voltage

4. Inter electrode gap

5. Concentration, temperature and flow rate of electrolyte

6. Tools

7. Micro-tool feed

REF.[7]](https://image.slidesharecdn.com/ecmparameters-171122073750/85/Electro-chemical-machining-parameters-15-320.jpg)

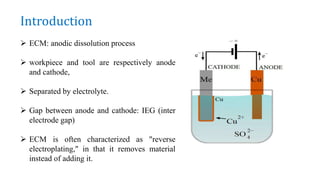

![3.Flow of electrolyte

• Nontoxic electrolyte should be used

• electrolyte is pumped from a storage tank via a pressure controller

• delivery systems and multi nozzle systems.

Variations of electrolyte condition along the machining

length

REF. [3]](https://image.slidesharecdn.com/ecmparameters-171122073750/85/Electro-chemical-machining-parameters-23-320.jpg)

![REF.[4]](https://image.slidesharecdn.com/ecmparameters-171122073750/85/Electro-chemical-machining-parameters-26-320.jpg)

![[References]

i. Venkatesan, K. "The study on force, surface integrity, tool life and chip on laser

assisted machining of inconel 718 using Nd: YAG laser source." Journal of

Advanced Research 8.4 (2017): 407-423

ii. Burger, M., et al. "Electrochemical machining characteristics and resulting surface

quality of the nickel-base single-crystalline material LEK94." Journal of

Manufacturing Processes 14.1 (2012): 62-70.

iii. Deconinck, D., et al. "Study of the effects of heat removal on the copying accuracy

of the electrochemical machining process." Electrochimica Acta 56.16 (2011):

5642-5649

iv. Chen, Xuezhen, et al. "Experimental research on electrochemical machining of

titanium alloy Ti60 for a blisk." Chinese Journal of Aeronautics 29.1 (2016): 274-

282..](https://image.slidesharecdn.com/ecmparameters-171122073750/85/Electro-chemical-machining-parameters-28-320.jpg)