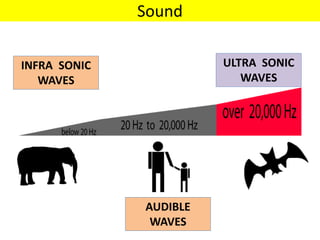

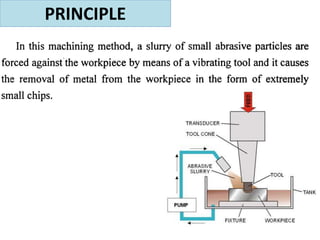

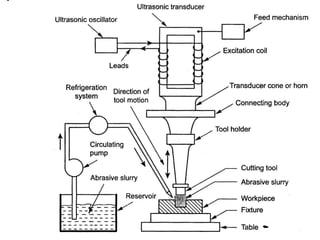

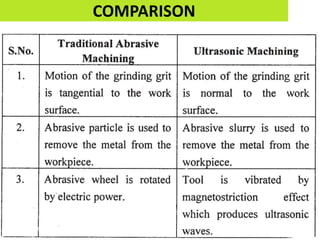

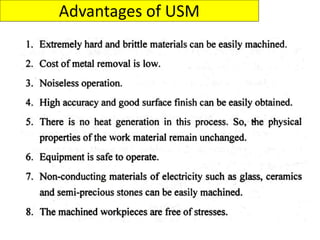

Ultrasonic machining (USM) uses high-frequency ultrasonic vibrations to remove material from a workpiece with an abrasive slurry. Key aspects of USM include:

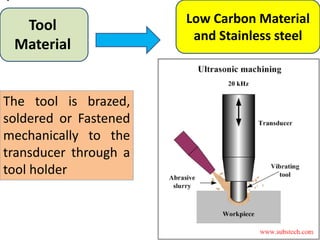

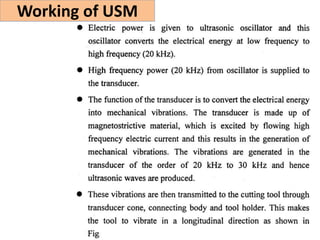

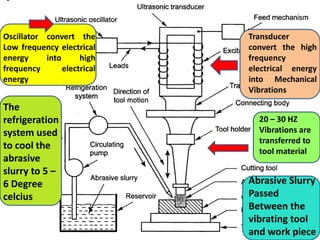

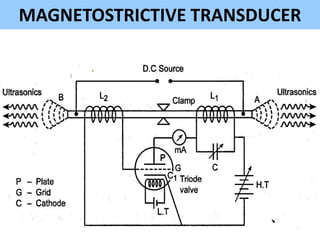

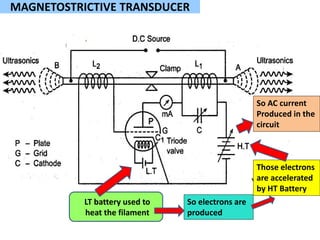

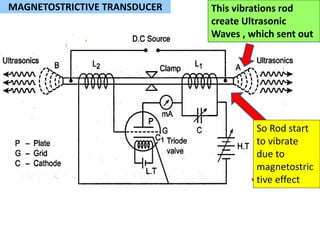

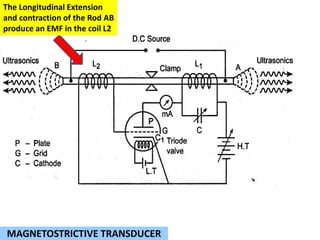

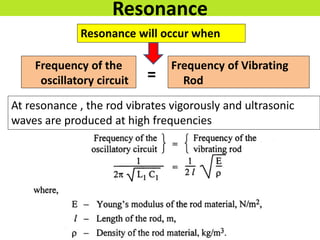

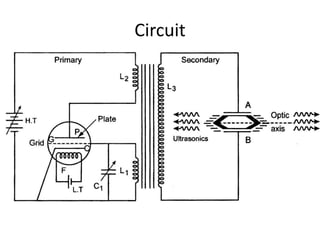

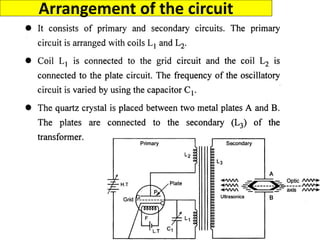

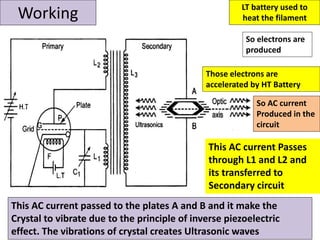

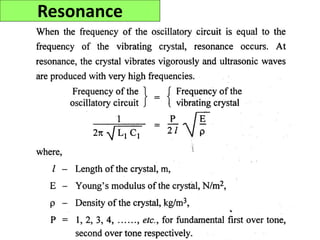

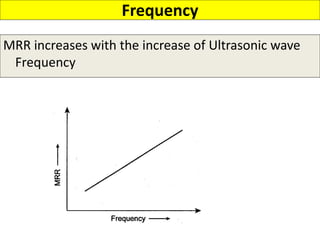

1. An ultrasonic generator produces high-frequency vibrations that are transmitted by a transducer to a tool.

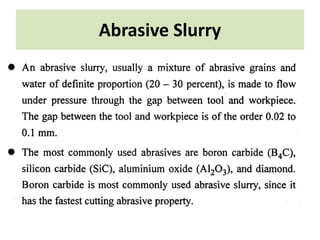

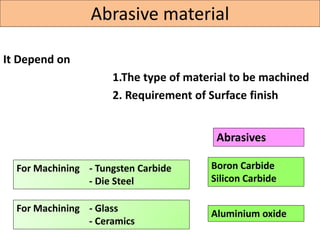

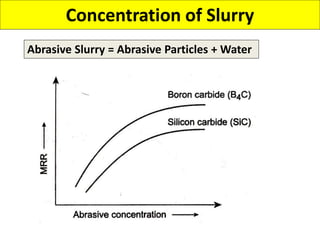

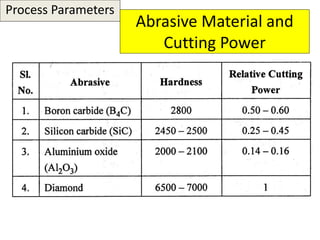

2. An abrasive slurry is fed between the vibrating tool and workpiece to facilitate material removal.

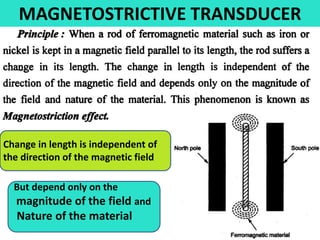

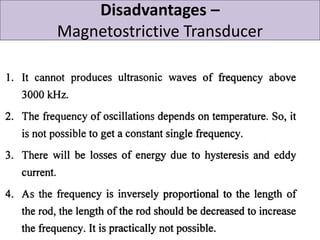

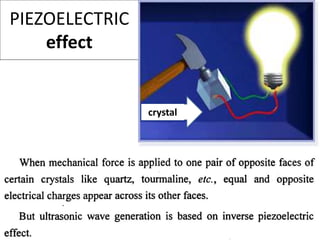

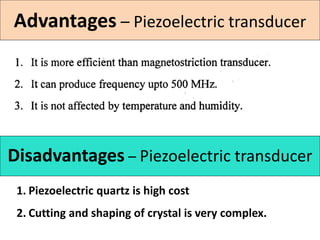

3. Common transducer types are magnetostrictive and piezoelectric, with piezoelectric being more efficient.

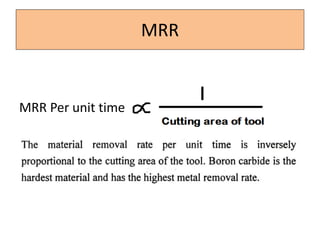

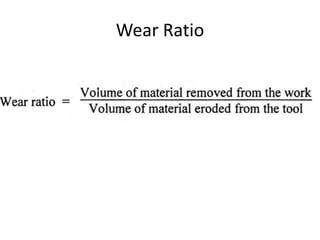

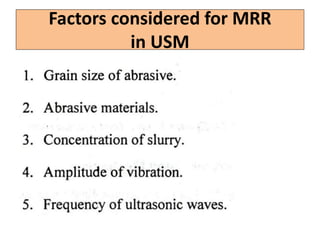

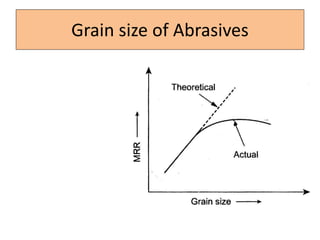

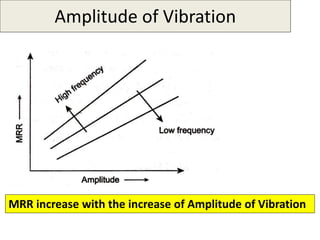

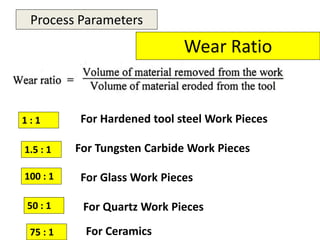

4. Process parameters like amplitude, frequency, abrasive properties influence the material removal rate and wear ratio.