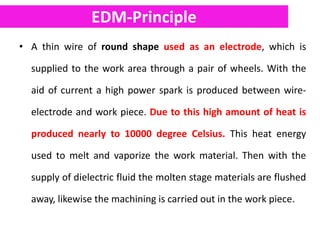

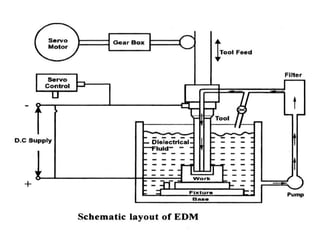

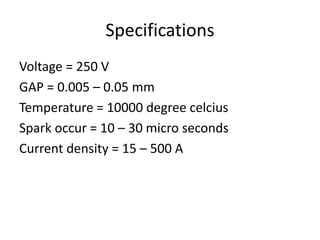

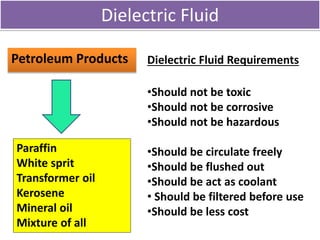

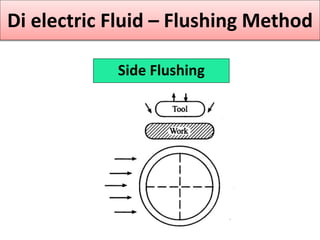

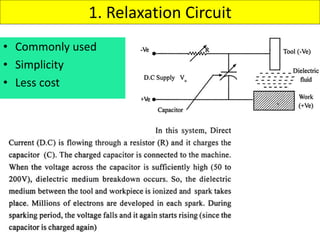

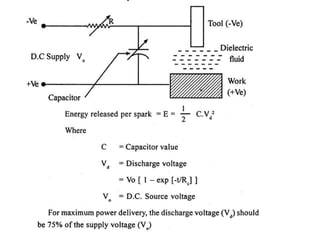

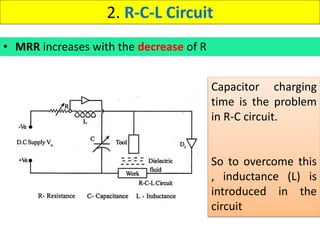

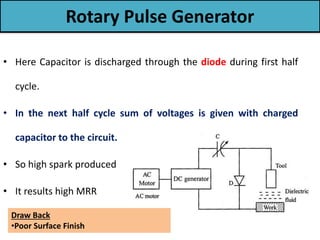

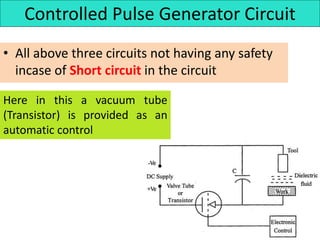

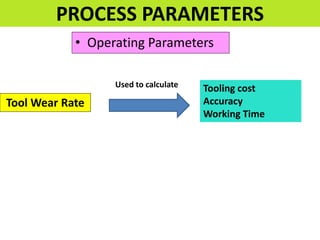

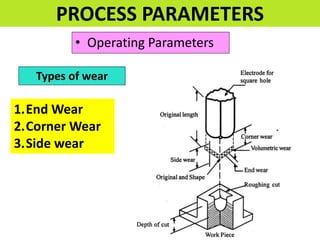

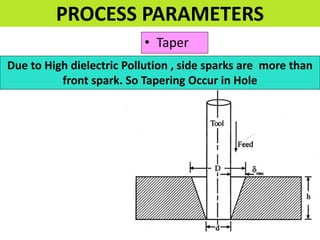

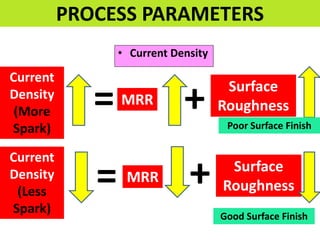

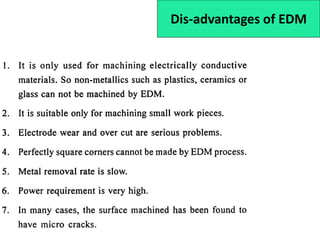

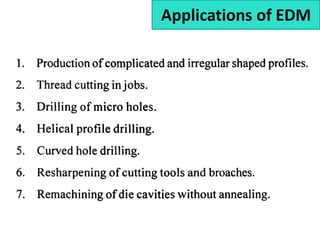

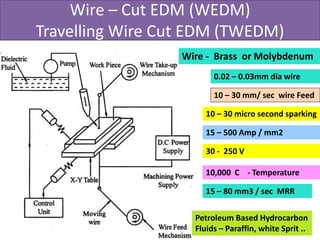

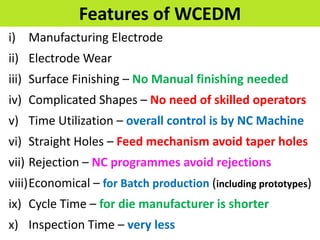

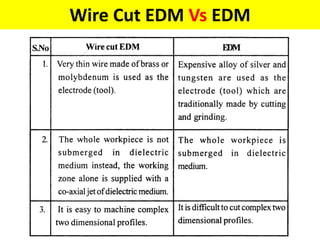

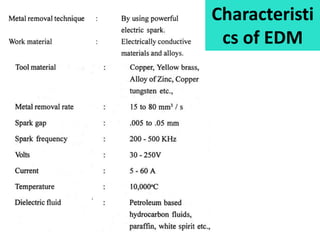

This document discusses electrical discharge machining (EDM). EDM uses electrical sparks to erode material from a workpiece. A thin wire electrode is used to produce high-power sparks between itself and the workpiece, reaching temperatures of 10,000 degrees Celsius. This heat melts and vaporizes the workpiece material, which is then flushed away by a dielectric fluid. The document discusses EDM principles, specifications, dielectric fluids, power generating circuits, process parameters including surface finish and current density, advantages and disadvantages of EDM, and applications for wire-cut EDM.