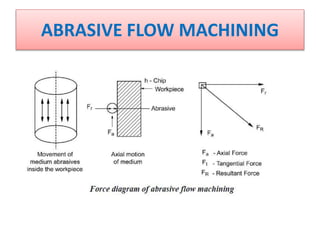

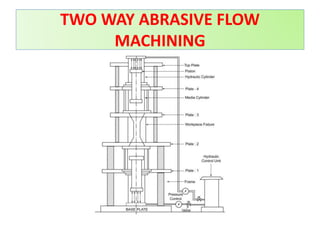

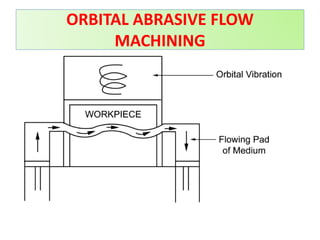

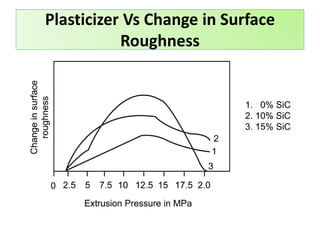

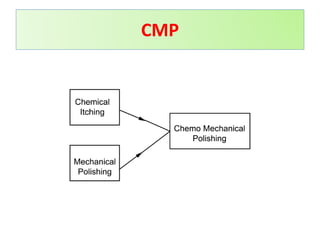

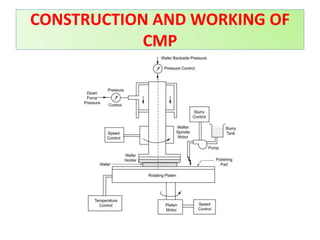

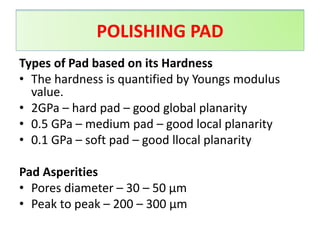

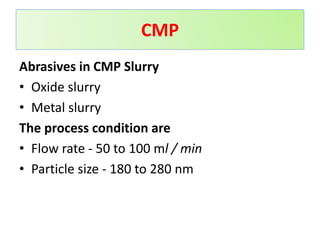

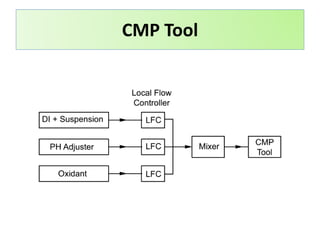

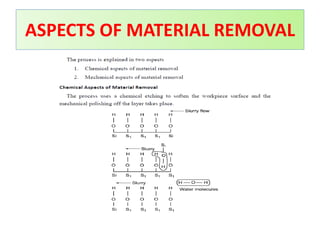

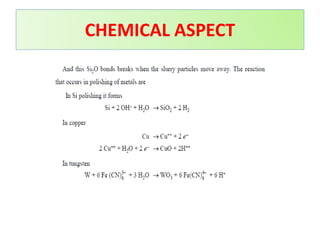

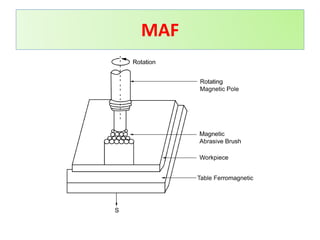

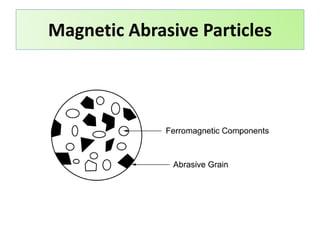

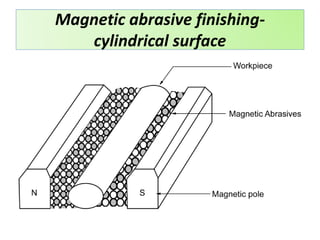

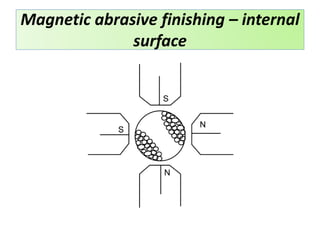

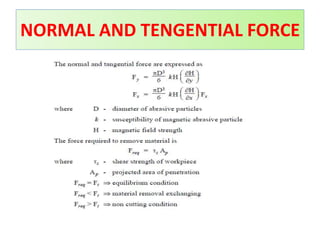

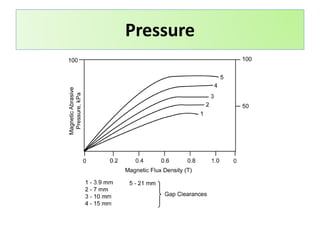

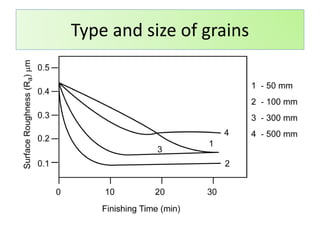

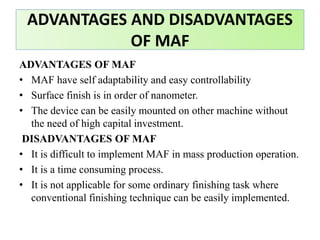

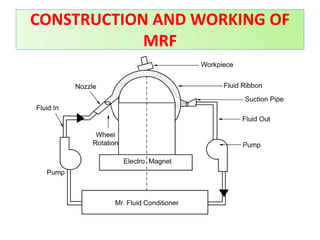

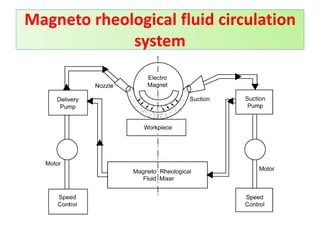

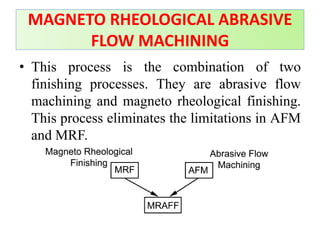

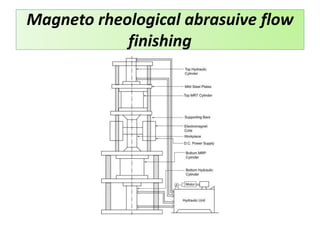

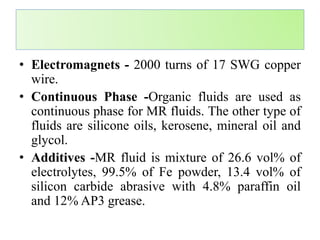

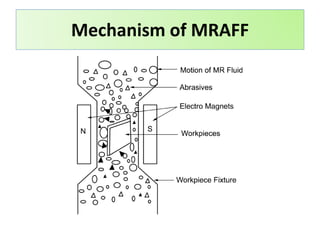

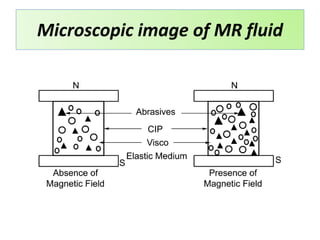

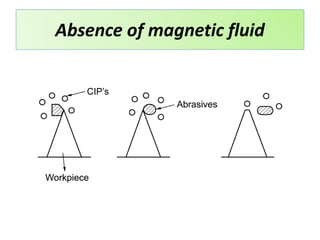

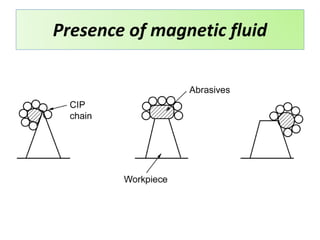

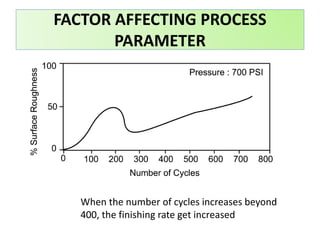

This document provides an overview of advanced nano finishing processes. It describes abrasive flow machining, chemo mechanical polishing, magnetic abrasive finishing, magneto rheological finishing, and magneto rheological abrasive flow finishing. For each process, it outlines the basic principles, construction and working, process parameters, advantages, limitations, and applications. Abrasive flow machining uses a semisolid abrasive media to remove small amounts of material from surfaces. Chemo mechanical polishing combines chemical etching and abrasive polishing, while magnetic abrasive finishing uses magnetic particles to form an abrasive brush for finishing. Magneto rheological finishing takes advantage of smart fluids that change viscosity in magnetic fields for precision mach