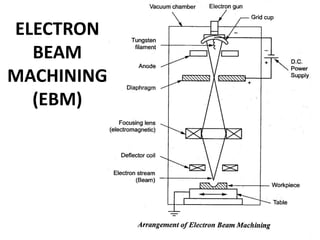

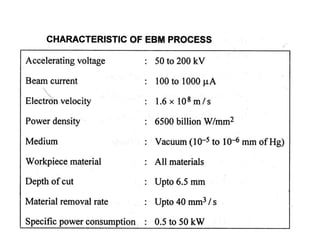

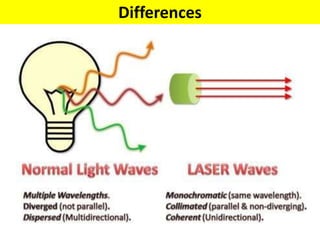

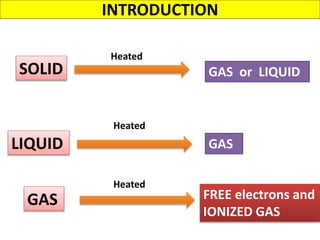

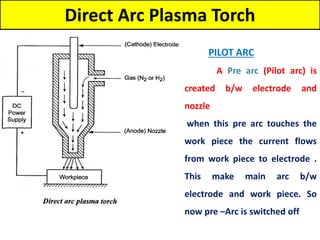

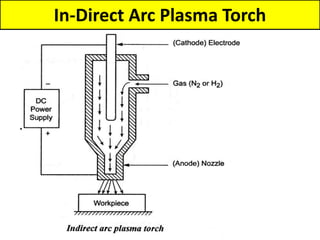

Thermal energy based machining processes like electron beam machining (EBM), laser beam machining (LBM), and plasma arc machining (PAM) work by focusing heat energy on a portion of the work material to melt and vaporize it. EBM works by focusing a beam of electrons, LBM uses a focused laser beam, and PAM uses an ionized gas plasma jet at very high temperatures. These processes can machine hard and exotic materials with high precision and no tool contact. However, they require specialized equipment, skilled operators, and have high operating costs. Common applications include cutting, drilling, welding, and surface treatment of metals.