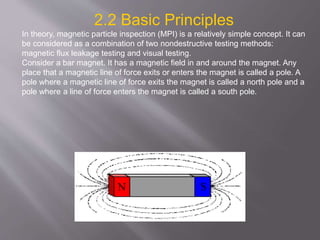

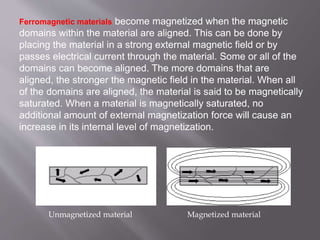

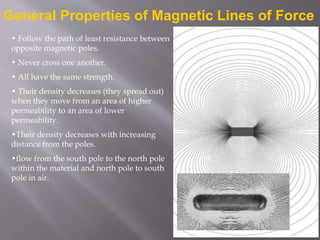

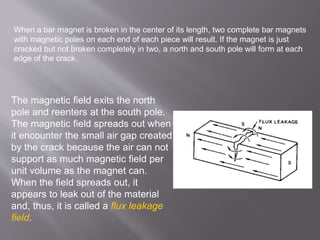

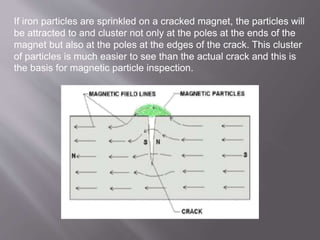

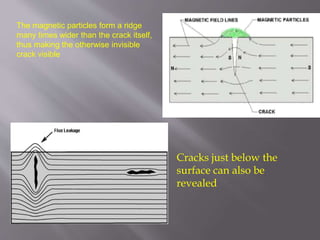

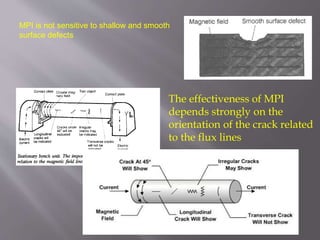

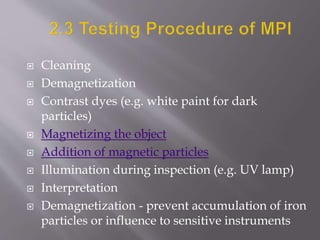

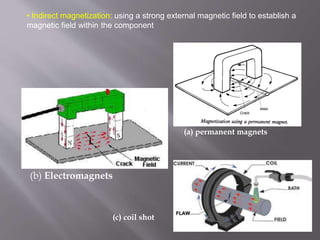

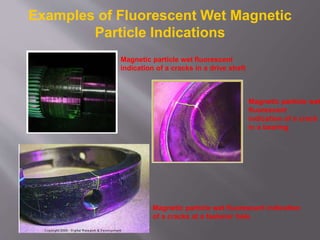

This document provides an overview of magnetic particle inspection (MPI), a nondestructive testing method used to detect surface and near-surface defects in ferromagnetic materials. It describes the basic principles of how MPI works by magnetizing a material and using magnetic particles to reveal defects that cause magnetic flux leakage. The document outlines the properties of materials in magnetic fields, the MPI process, standards, advantages, limitations, and examples of MPI indications.