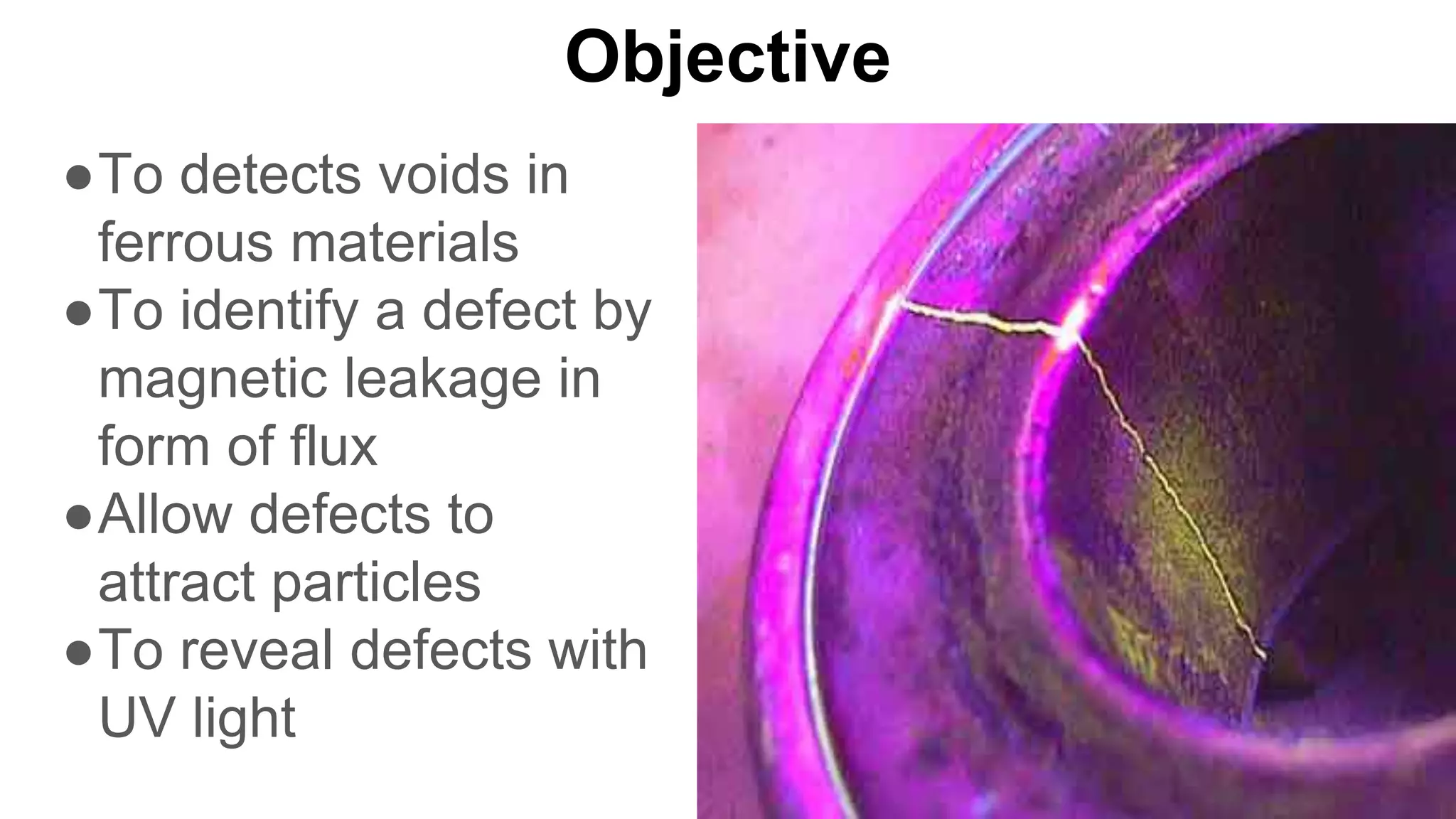

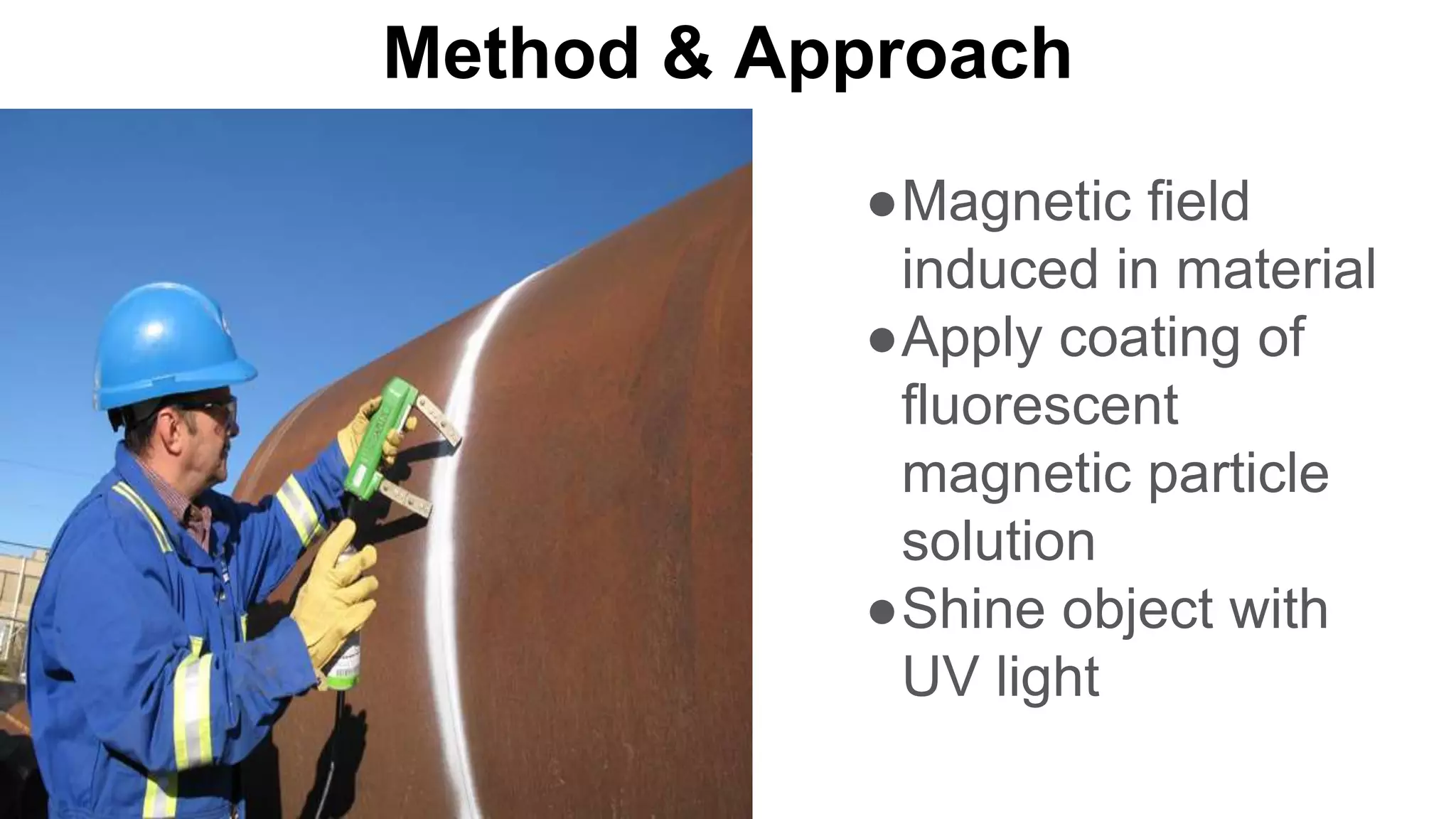

Magnetic particle inspection detects defects in ferromagnetic materials by magnetizing the material and applying iron-based particles or wet fluorescent dye. Defects are revealed under ultraviolet light as the particles cluster at discontinuities in the magnetic field caused by the defect. Image processing techniques can further analyze inspection images to enhance defect detection. While providing accurate detection of surface and near-surface flaws, magnetic particle inspection is time-consuming and subjective, but digital image analysis automates some inspection tasks.