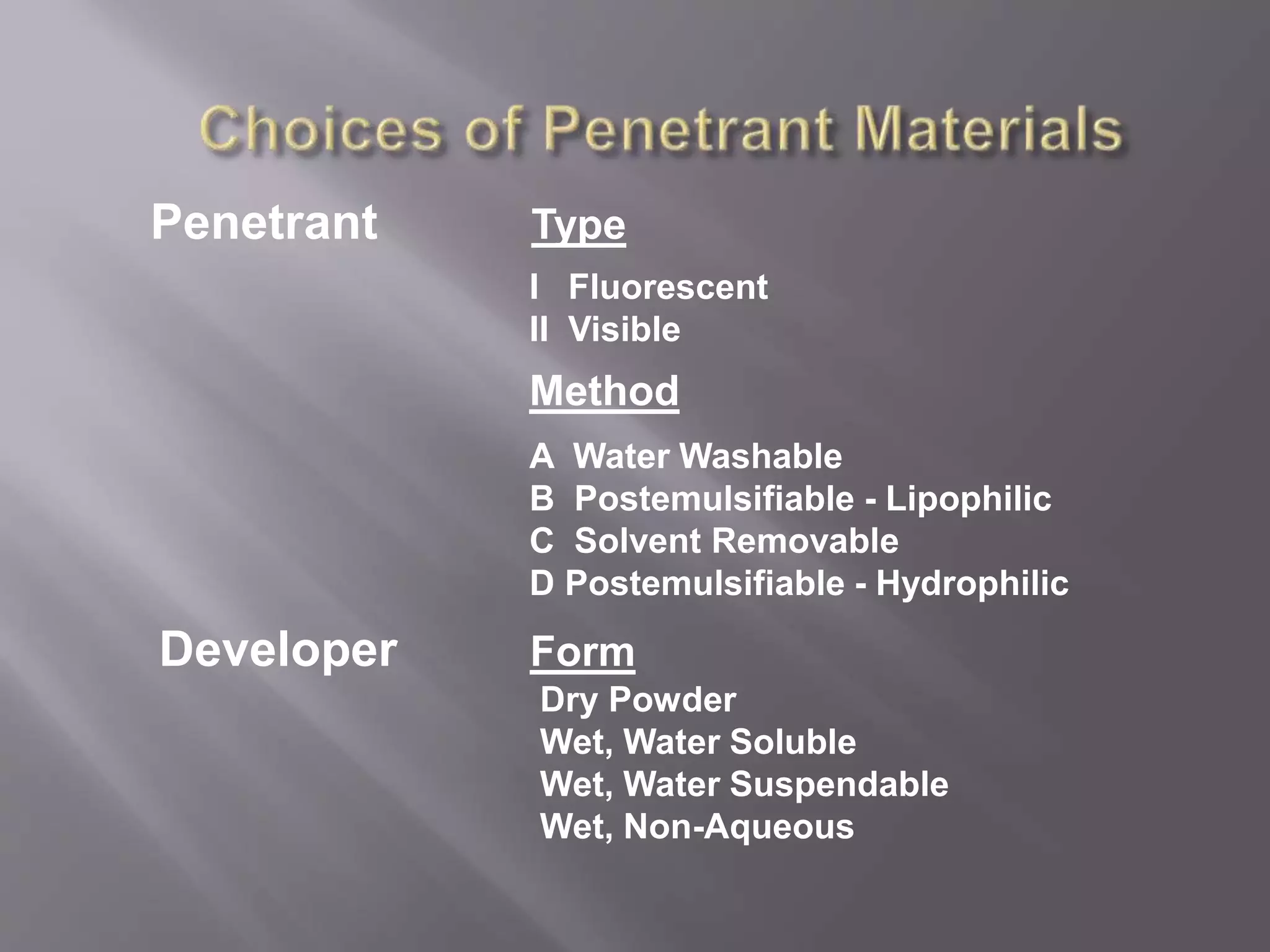

Penetrant testing (PT) is a nondestructive testing method used to detect surface-breaking defects in materials. It works by applying a liquid penetrant that seeps into defects, then using a developer to draw the penetrant back to the surface where it can be seen. The process involves cleaning, applying penetrant, removing excess, applying developer, and inspecting under UV or white light. Proper selection of penetrant type and sensitivity level is important to optimize defect detection without excessive false indications. PT can find cracks, pores, and other discontinuities in metals and some non-metals.