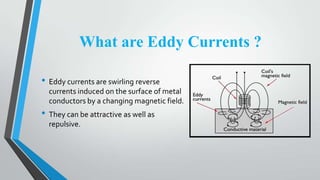

Eddy current brakes use magnetic fields to induce eddy currents in a conductive surface, like a metal disc, which then generate drag due to Lenz's law. They have advantages over traditional braking systems like being more eco-friendly since they don't produce wear debris and can generate higher braking forces for high speed systems. An eddy current brake consists of a stationary electromagnet and a solid metal disc rotor with a small air gap between them. When the magnetic field changes due to the disc's rotation, eddy currents are induced in the disc which interact with the magnetic field to slow the disc's rotation via electromagnetic braking forces without direct contact. Eddy current brakes are used in applications like trains