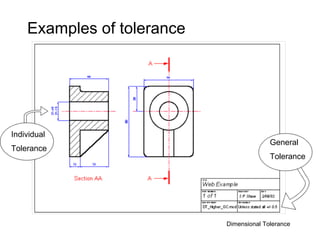

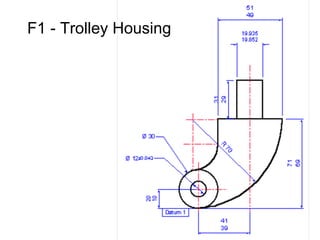

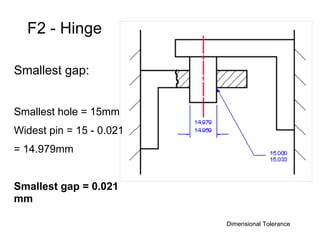

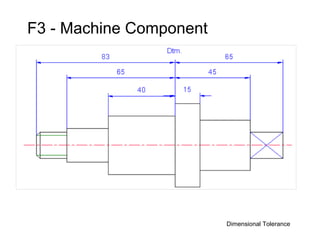

British standards define technical, manufacturing, and safety guidelines for UK industry. Dimensional tolerances account for permissible errors in achieving exact sizes during manufacturing. The choice of tolerance depends on the manufacturing method, item size, cost considerations, desired quality, material properties, and interfaces. Tolerances can be general, applying to all non-functional dimensions, or individual, specifying tolerances for critical dimensions. Examples show individual tolerances for functional parts and a general tolerance in a title block.