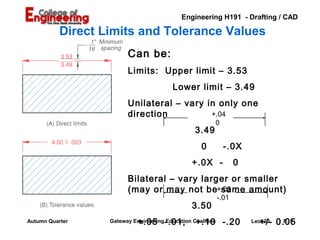

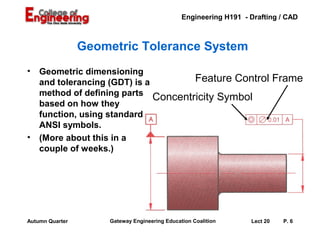

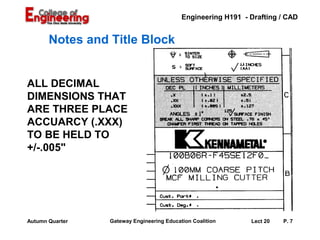

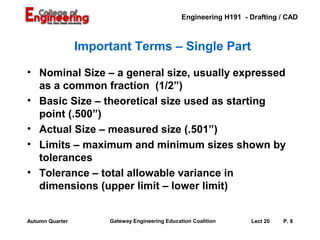

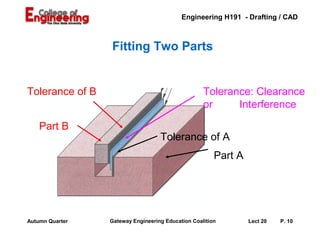

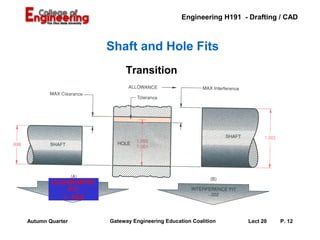

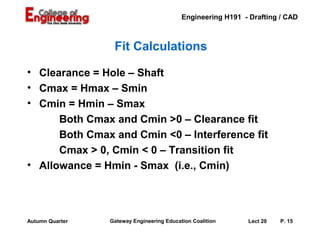

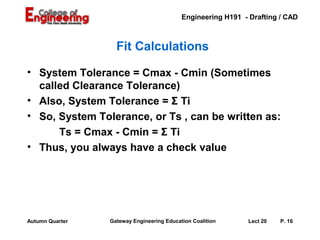

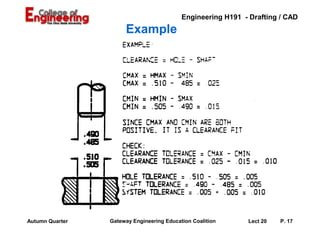

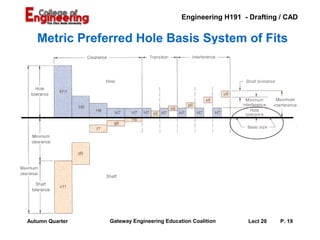

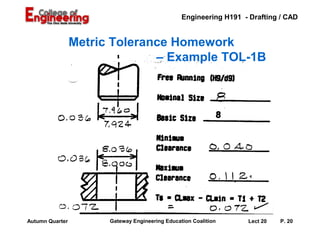

This document summarizes a lecture on fits and tolerances in engineering drafting. It defines tolerance as the total amount a dimension can vary between its maximum and minimum limits. It discusses different ways to express tolerances, including direct limits, geometric tolerancing, and general notes. Key terms are introduced, such as nominal size, basic size, actual size, limits, clearance fits, interference fits, and transition fits. Standard tables for shaft and hole fits in both English and metric units are referenced. Examples are provided for calculating fits and tolerances.