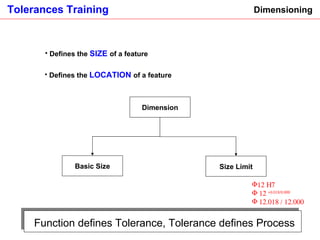

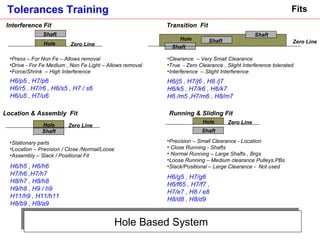

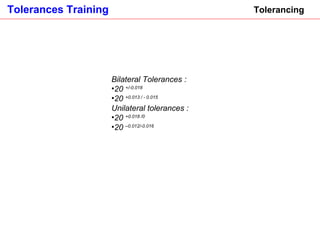

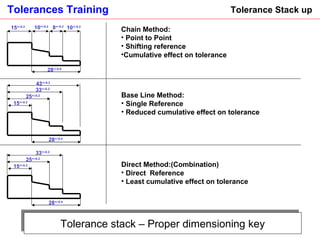

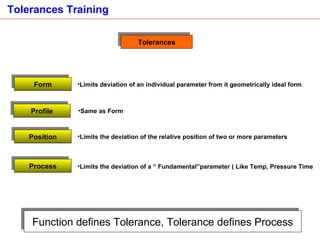

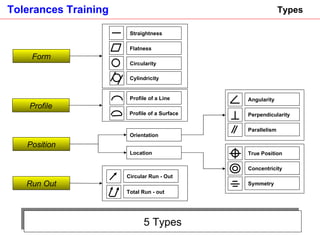

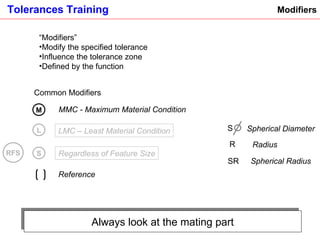

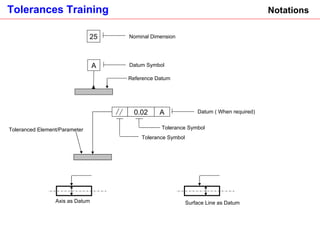

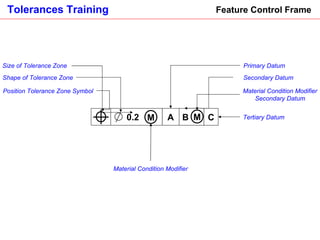

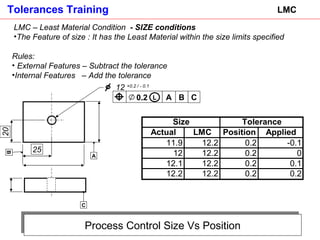

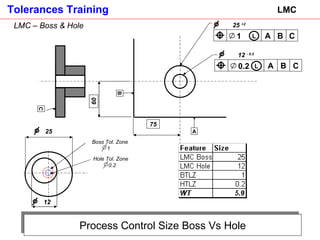

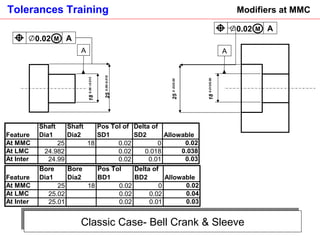

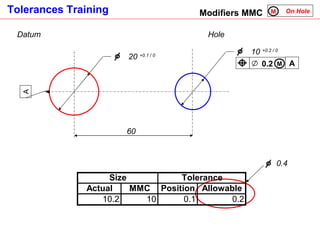

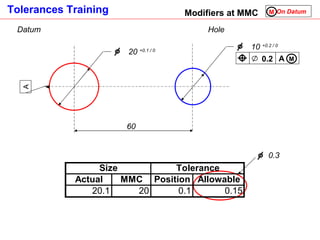

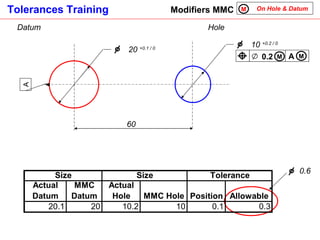

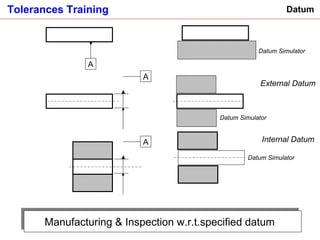

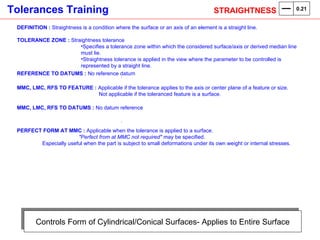

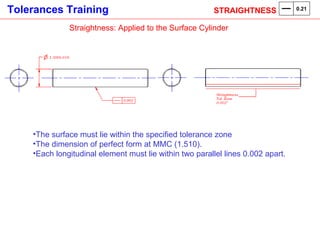

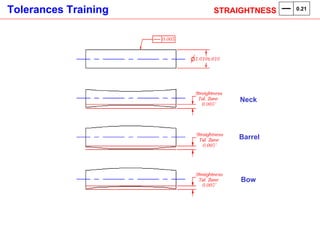

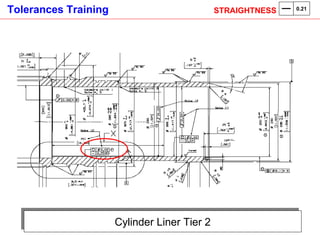

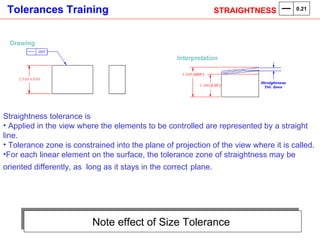

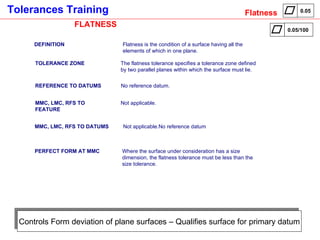

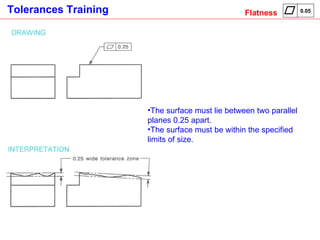

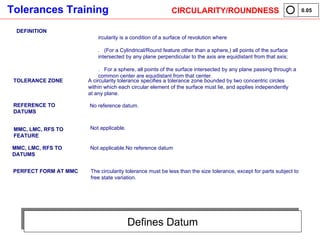

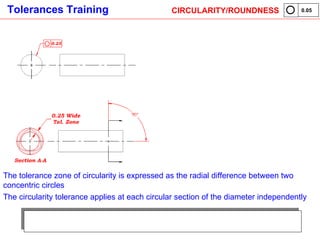

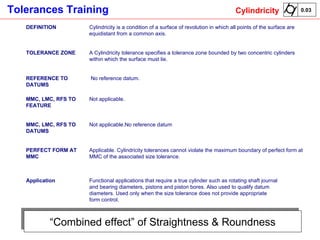

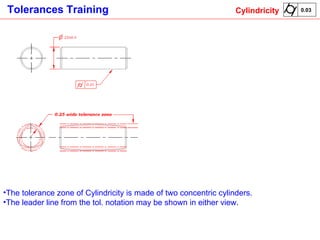

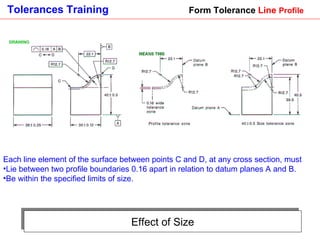

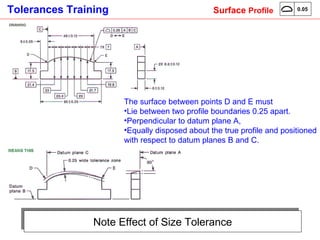

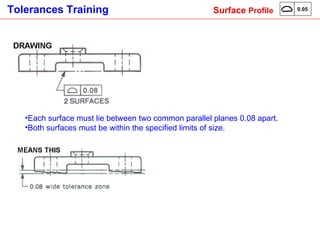

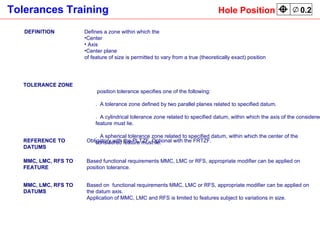

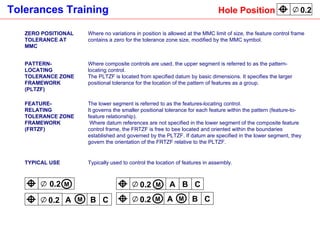

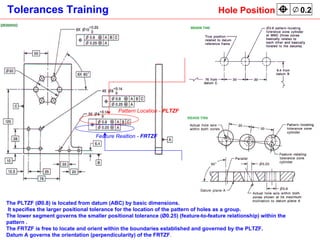

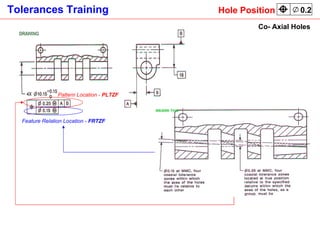

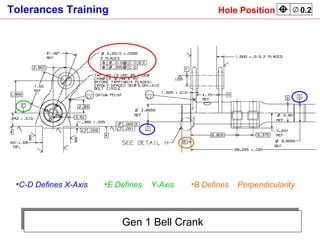

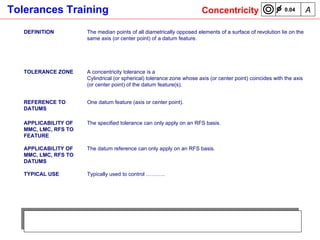

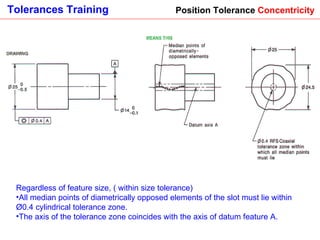

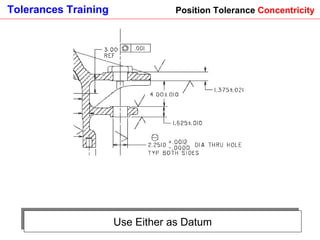

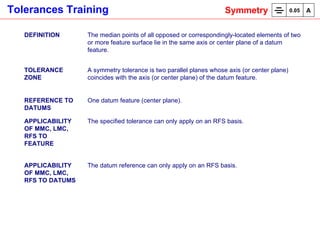

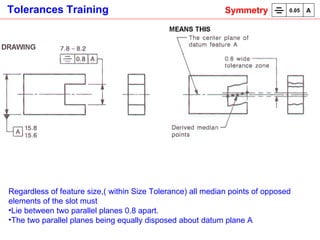

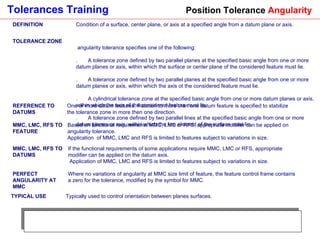

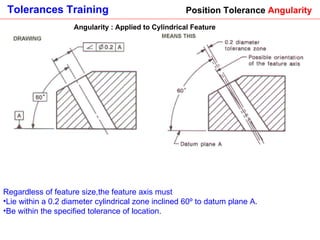

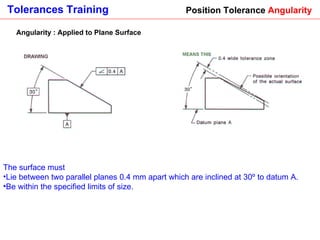

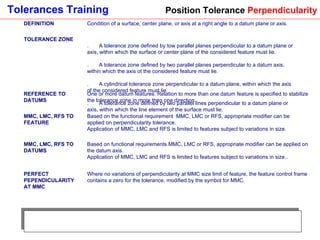

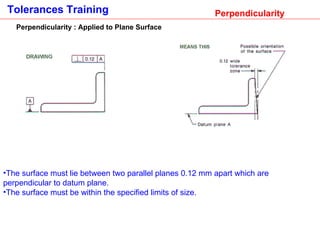

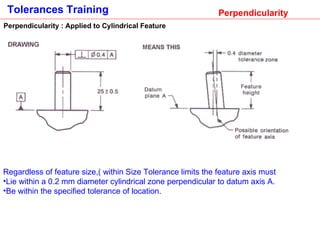

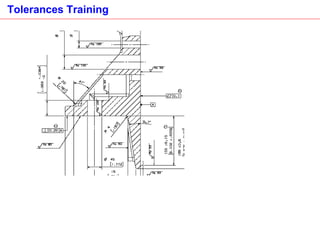

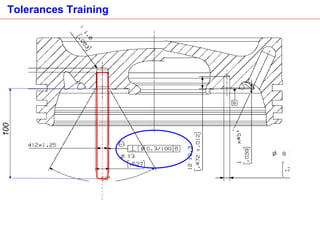

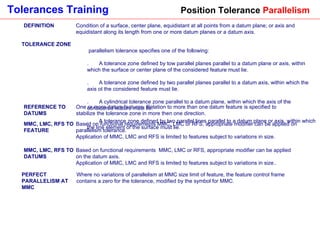

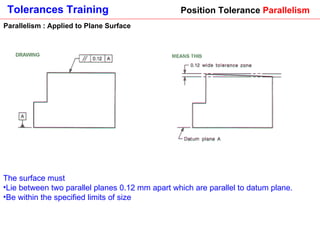

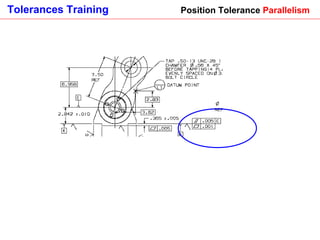

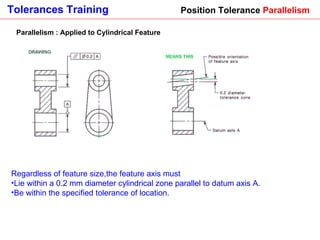

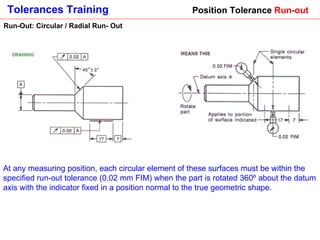

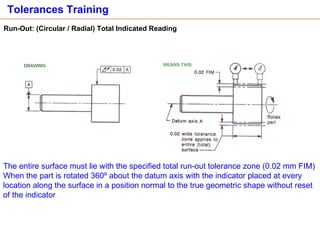

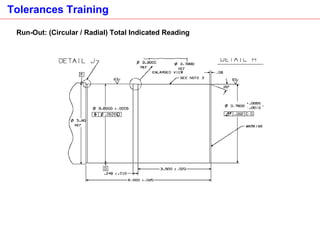

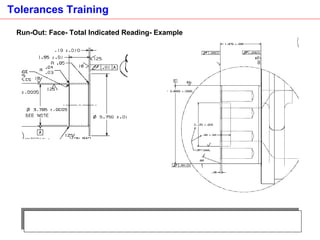

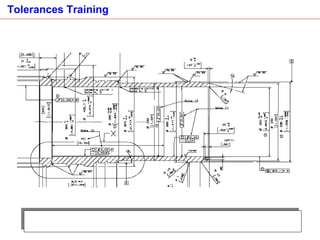

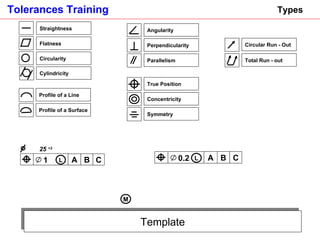

The document provides a comprehensive overview of geometric dimensioning and tolerancing (GD&T) principles, including various types of tolerances, fit systems, and modifiers as per ANSI Y14.5M-1988 standards. It details the calculations for tolerance stack-up methods, the definitions of form, orientation, and location tolerances, as well as the application of modifiers like maximum and least material condition. Additionally, it discusses the relationship between dimensions, tolerances, and the control of assembly processes in engineering design.